Foldable, stackable and traceable turnover box

A turnover box and traceable technology, applied in the field of tools, can solve the problems of difficult stacking, easy generation of paper scraps, high cost of use, etc., and achieve the effect of increasing the number of transportation, reducing the occupied space, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

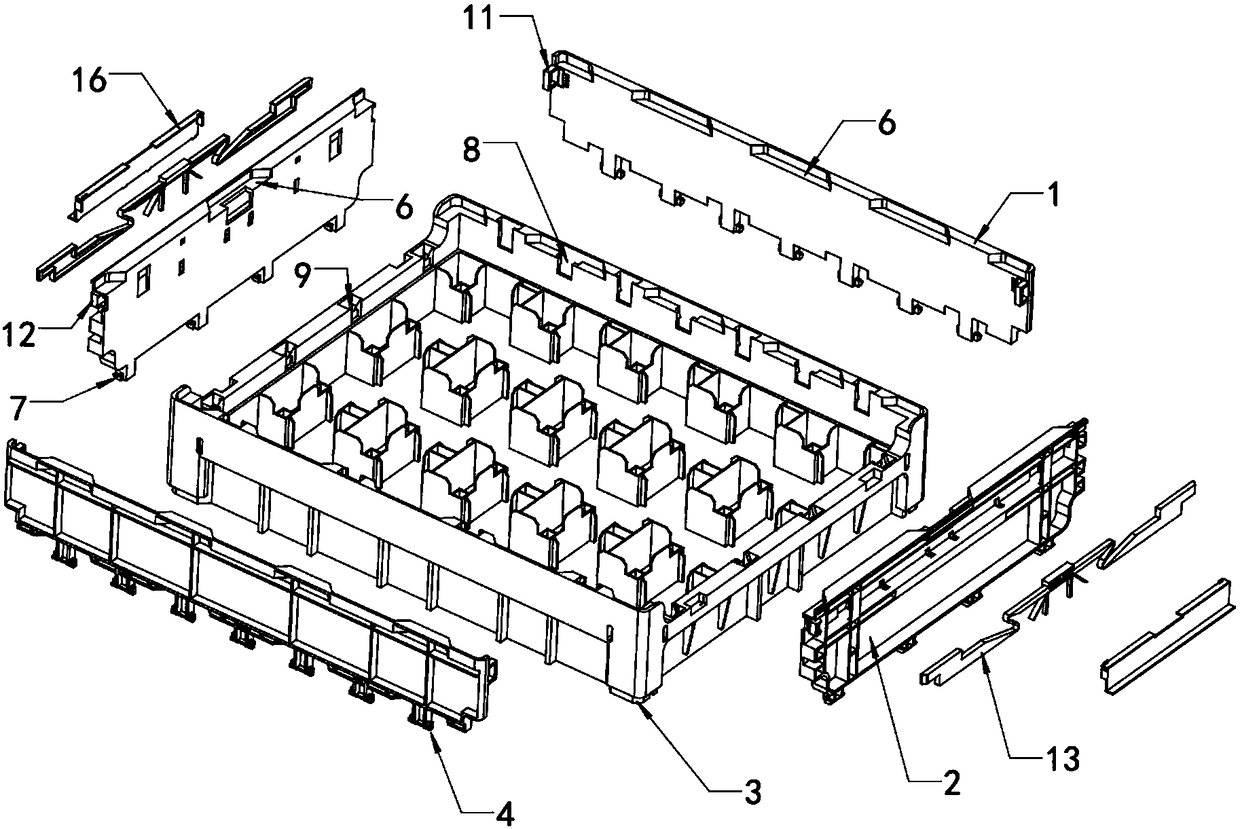

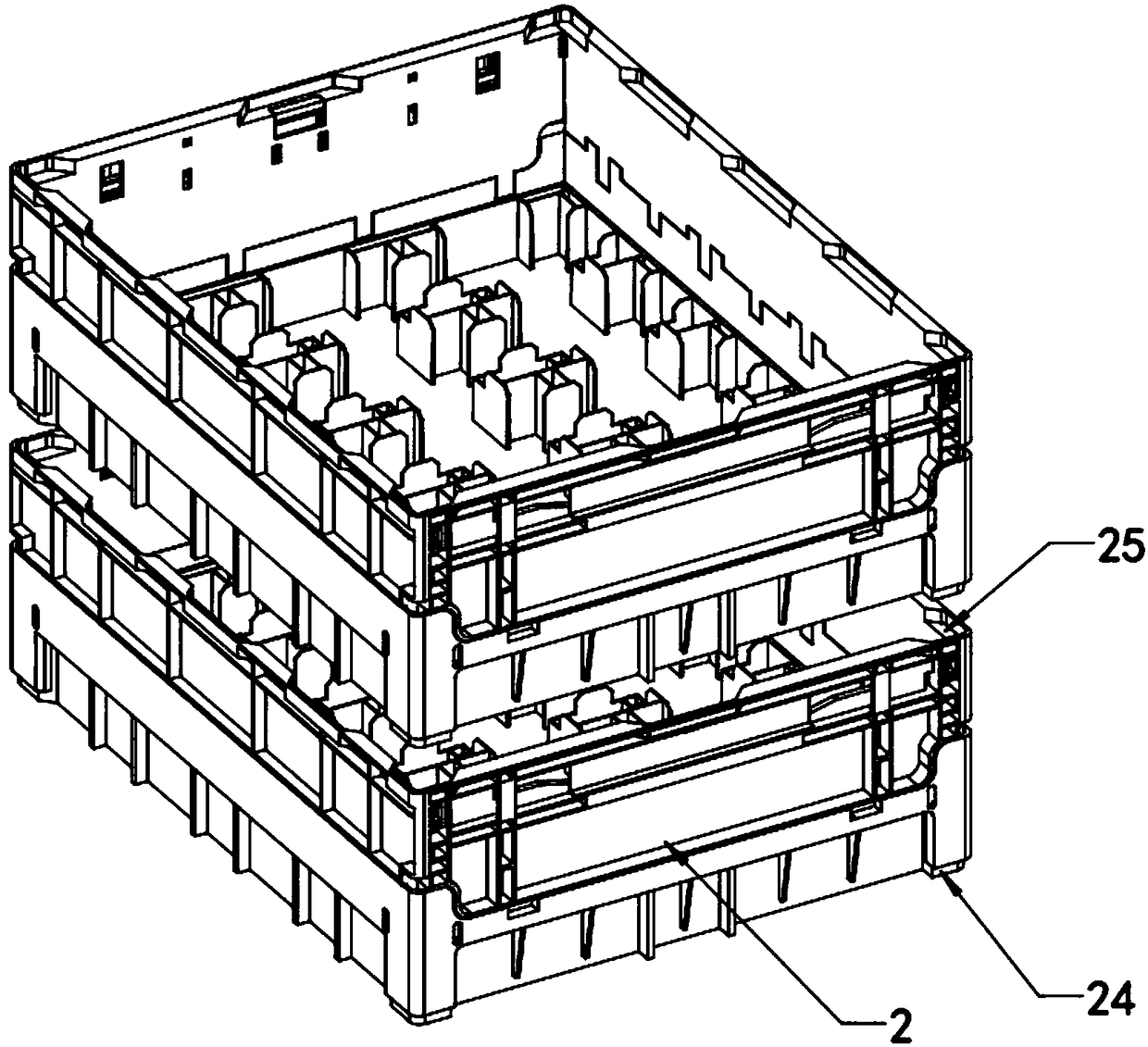

[0029] like figure 1 and figure 2 As shown, a foldable, stackable and trackable turnover box includes a foldable long board 1, a side panel 2 and a bottom board 3, two foldable long boards 1, two side panels 2 and a bottom board 3 form a frame, and the foldable long board 1 The board 1 and the side panel 2 have a smooth inner surface and an outer surface with reinforcing ribs, and a plurality of protruding first buckles 4 are arranged on the bottom of the folded long board 1 , and on both sides of the plurality of first buckles 4 A protruding trapezoidal surface 5 is provided at intervals to form a first buckle 4 and a first buckle 4 with a trapezoidal surface 5 is continuously arranged at the bottom of the folding long board 1 , and the folding long board 1 and the side panel 2 The top of the top is provided with trapezoidal grooves 6 at intervals, the long bottom of the trapezoidal grooves 6 is an inward opening, and the bottom of the side panel 2 is provided with a plural...

Embodiment 2

[0036] like Figure 8 As shown, compared with the above-mentioned embodiment, the difference of this embodiment is that a plurality of rectangular grooves 18 on the bottom surface and arc-shaped grooves 19 matching the arc surface of the transformer are arranged at intervals on the bottom plate 3, and the rectangular grooves 18 on the bottom surface There are chamfers at the ribs at the assembly height, and the rectangular grooves 18 and arc grooves 19 on the bottom are used to place the current transformers. In this embodiment, there are two rows of five rectangular grooves 18 with equal spacing on the bottom and the clamping transformers. Twenty arc grooves 19 on the arc surface.

Embodiment 3

[0038] like Figure 9 As shown, compared with the above-mentioned embodiment, the difference of this embodiment is that the bottom plate 3 is arranged at intervals with a plurality of rectangular grooves 20 composed of baffle ribs and bones and thin-walled grooves 21 matching the shape of the product shell. In the example, the rectangular grooves 20 and the thin-walled grooves 21 are arranged in two parallel rows, ten grooves in total.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com