A wire drawing processing device for the outer surface of stainless steel pipe

A stainless steel tube and wire drawing processing technology, which is applied in the direction of grinding drive devices, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult adjustment of the compression degree between the grinding roller and the stainless steel tube, low control accuracy, and slow wire drawing efficiency. Achieve good processing effect, precise control effect and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

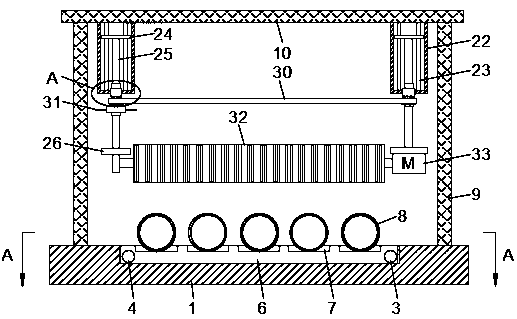

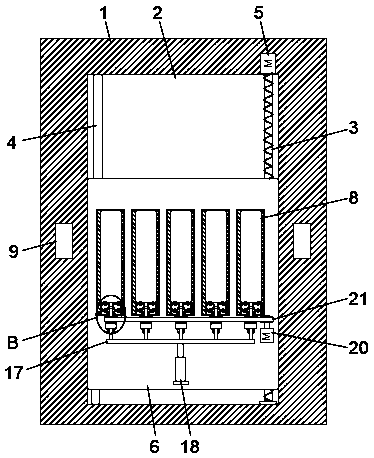

[0024] refer to Figure 1-5 , a stainless steel pipe outer surface wire drawing processing device, including a base 1, the upper end of the base 1 is provided with a chute 2, the inside of the chute 2 is provided with a threaded rod 3 and a first limit rod 4 in parallel, and on the inner wall of the chute 2 The first motor 5 is fixedly installed, and one end of the threaded rod 3 is fixedly connected with the output rod of the first motor 5, and a slide plate 6 is installed on the threaded rod 3 and the first limit rod 4, and the slide plate 6 and the threaded rod 3 threaded connection, the upper surface of the slide plate 6 is equidistantly provided with a plurality of placement slots 7, and a stainless steel tube 8 is placed in each placement slot 7, and the surface of the slide plate 6 is provided with a limit adjustment mechanism for use with multiple stainless steel tubes 8 .

[0025] The limit adjustment mechanism includes a bracket 11, a rotating shell 12, a movable ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com