Tooling for pipe processing

A pipeline and tooling technology, applied in the field of welding pipeline flange tooling, can solve the problems of reducing work efficiency, slipping on the ground, smashing and other problems, and achieving the effect of preventing personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the present invention, the embodiments of the present invention will be explained in detail below with reference to the accompanying drawings.

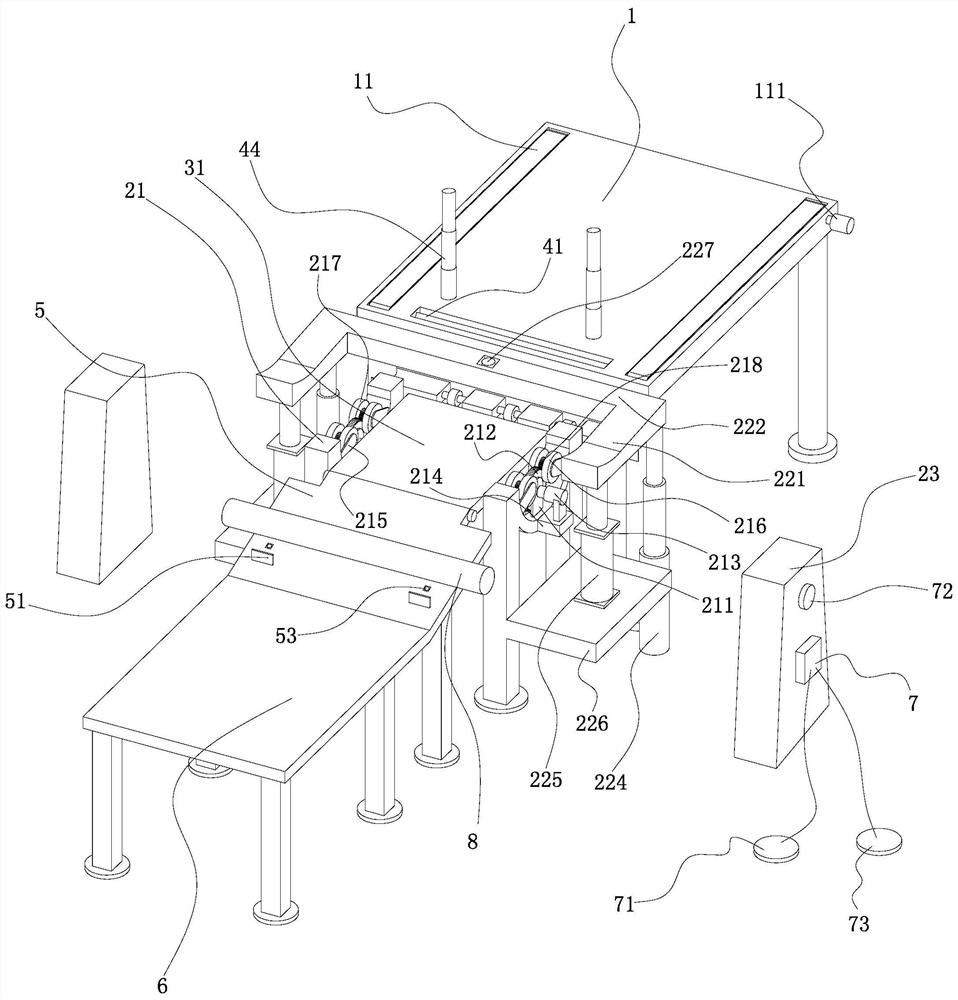

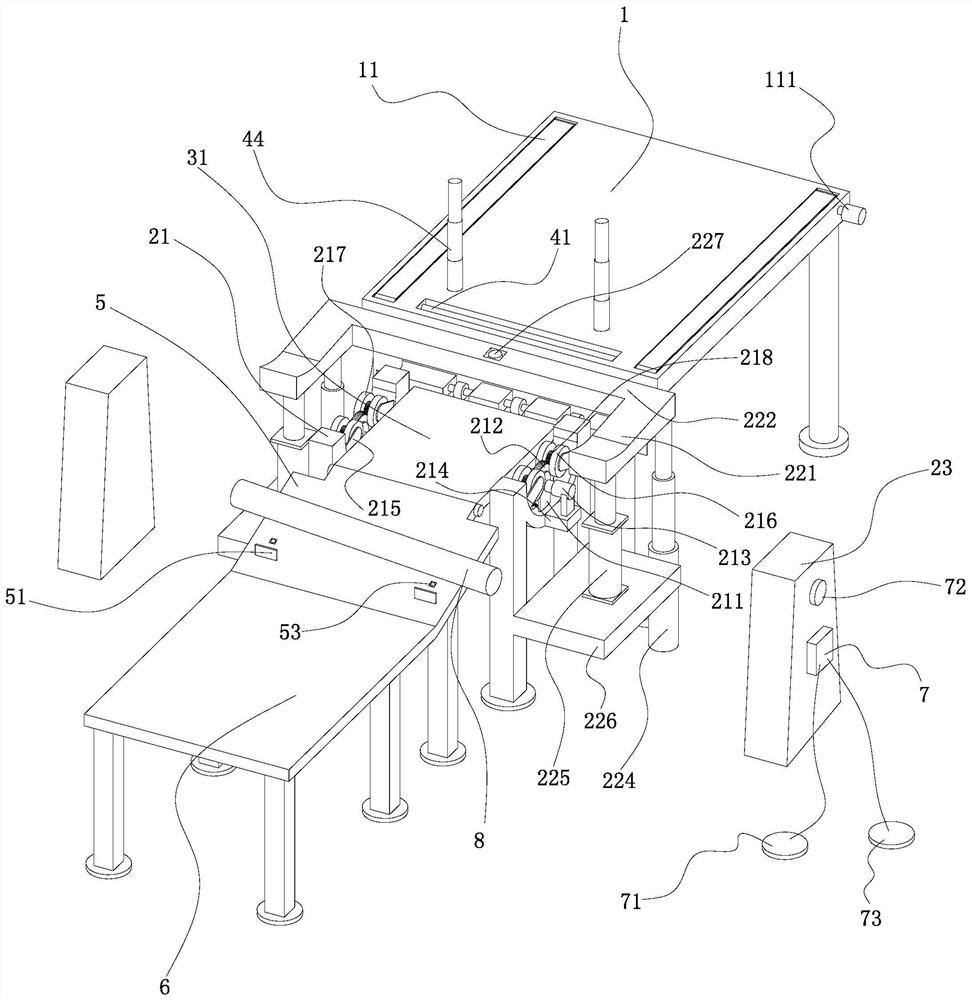

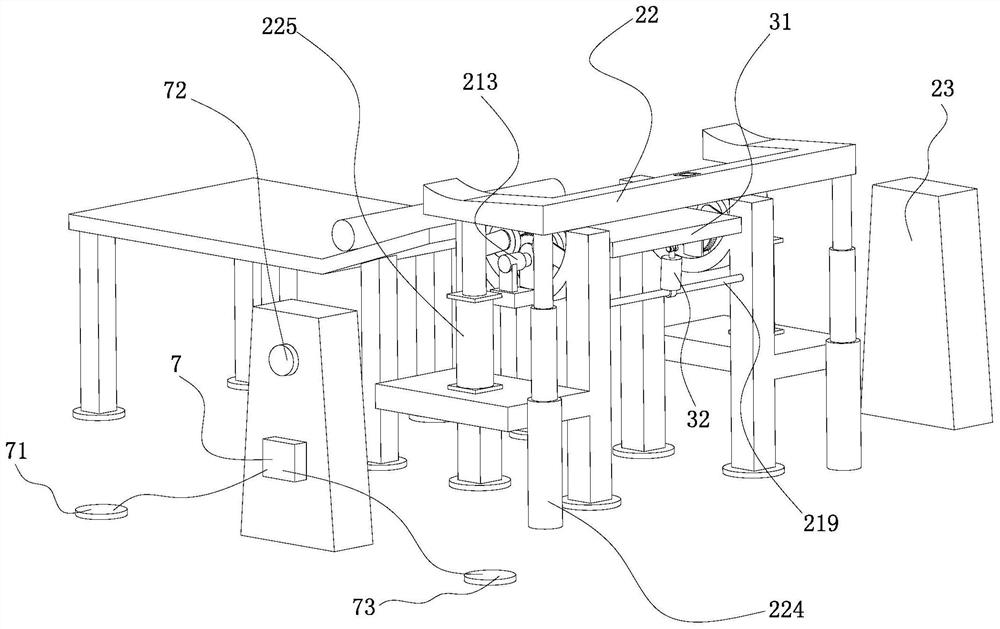

[0041] As attached figure 1 Attached Picture 11 As shown, the present invention includes a pipe placement frame 1, a positioning mechanism 2, a pushing mechanism 3, a blocking mechanism 4, a slide frame 5, a horizontal frame 6 and a controller 7.

[0042] The pipe placing rack 1 is provided with symmetrical strip grooves on the left and right sides, and a conveyor belt 11 is arranged in the strip groove. The two conveyor belts 11 are 0.5-1.5 cm higher than the upper surface of the pipe placing rack 1, preferably The height is 1cm. The front and rear ends of the two conveyor belts 11 are respectively connected by a rotating roller, and one side of the rotating roller is drivingly connected with a driving motor I111; the driving connection may be the motor shaft of the driving motor I111 and the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com