A Safe and Reliable Active Oil Static Eliminator

A static eliminator and oil technology, applied in the direction of static electricity, instruments, electrical components, etc., can solve the problems of detonating oil and gas, occurrence of danger, electric sparks in pipelines, etc., to achieve the effect of eliminating static electricity, avoiding the danger of explosion, and easy ionization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

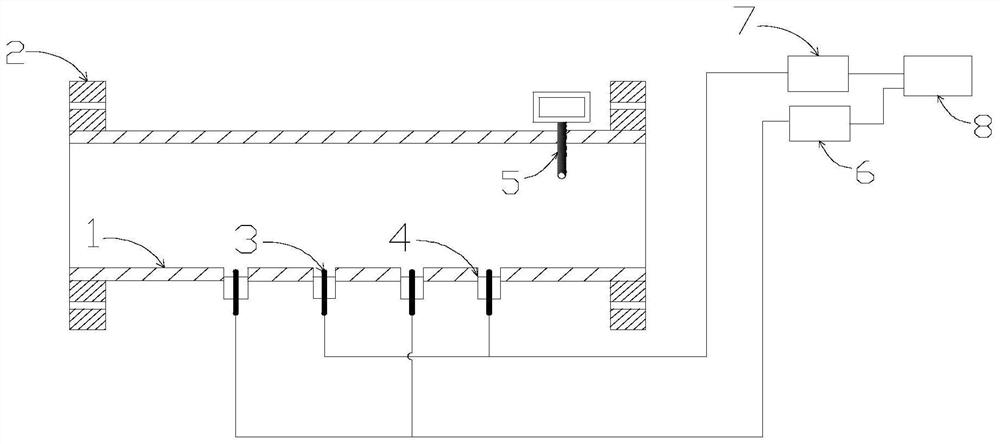

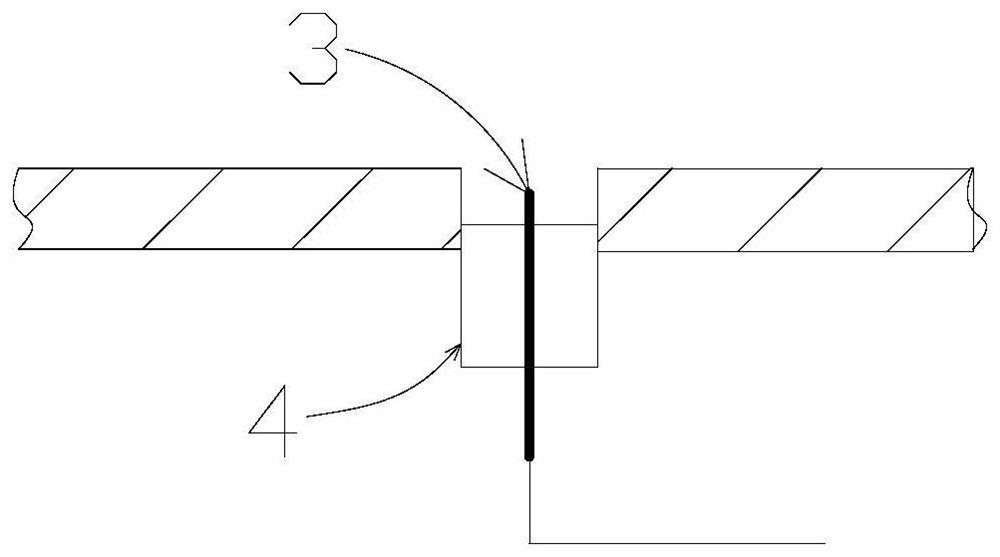

[0018] to combine Figure 1 to Figure 2 As shown, the specific implementation of a safe and reliable active oil static eliminator is as follows:

[0019] A safe and reliable active oil static eliminator, comprising pipeline 1, connecting flange 2, discharge needle 3, insulating block 4, oil charge density monitor 5, positive voltage generating device 6, negative voltage generating device 7 and Control device 8. The oil product charge density monitor 5 is arranged on the pipeline 1, the oil product charge density monitor 5 is connected with the control device 8 through the data line, the control device is respectively connected with the positive voltage generator 6 and the negative voltage generator 7, and the positive voltage generator 6 and the negative voltage generating device 7 are respectively connected to the discharge needle 3 through wires. The discharge needle 3 is arranged at the bottom of the pipe 1, and the discharge needle 3 is wrapped in the insulating block 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com