vehicle control system

A vehicle control system and vehicle technology, applied to bicycle control systems, bicycle brakes, bicycle accessories, etc., can solve problems such as easy corrosion and short service life, and achieve the effect of reducing frictional resistance and precise actuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples illustrate possible implementations of the present invention, but are not intended to limit the protection scope of the present invention.

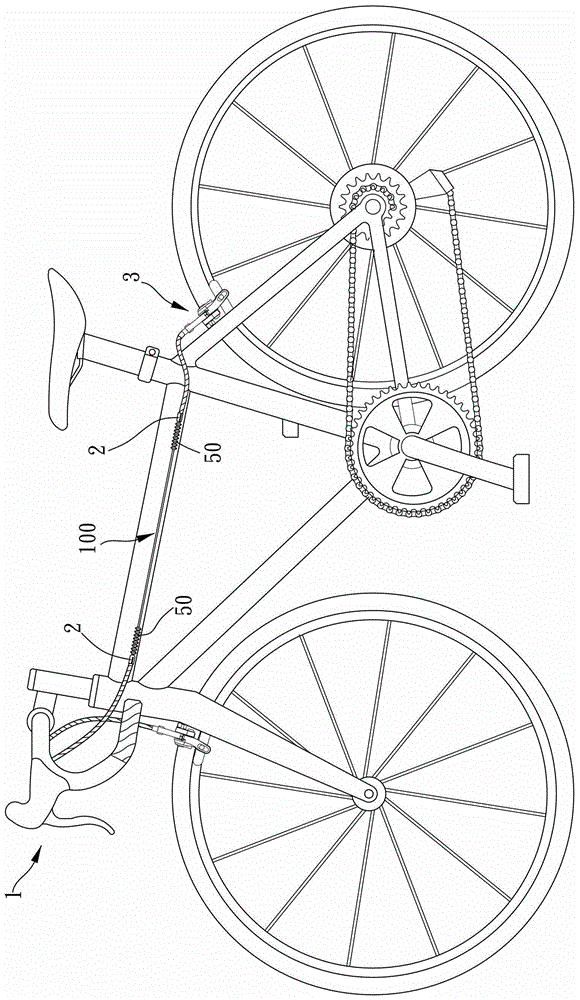

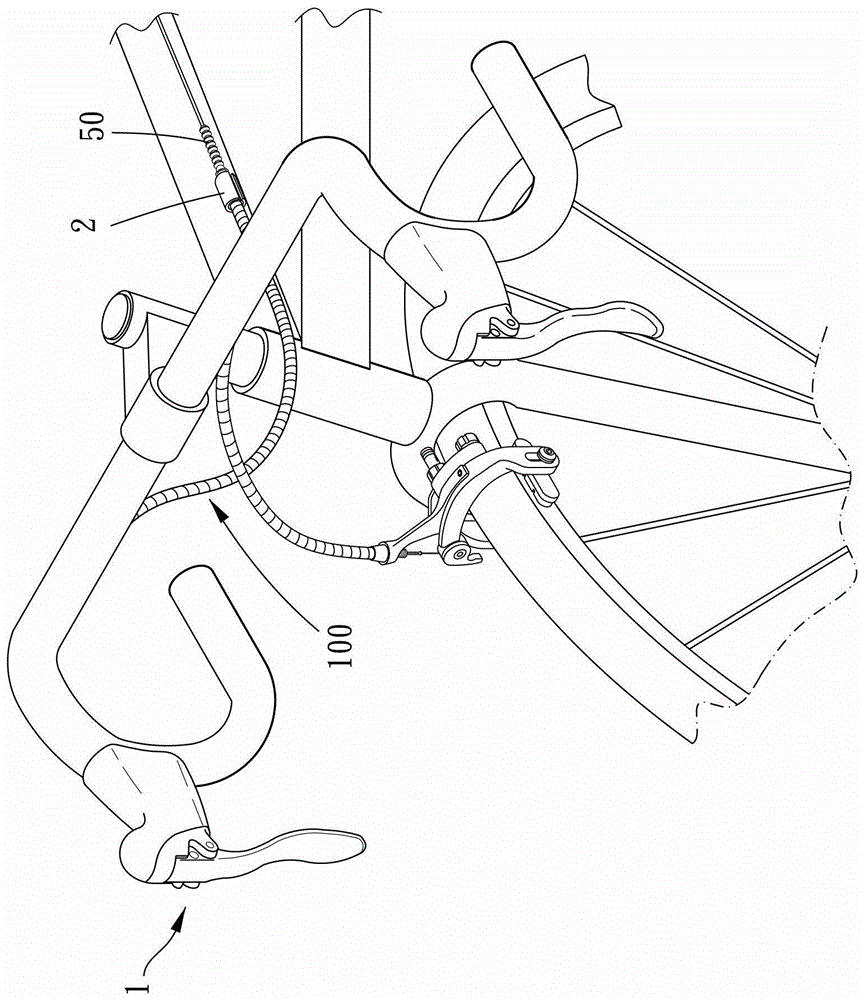

[0027] Please refer to figure 1 and figure 2 , which shows a preferred embodiment of the present invention, the vehicle control system 100 of the present invention is for installation in a vehicle (such as bicycle, locomotive, automobile), and the vehicle is provided with an operable actuating part 1, at least two for fixing The fixed part 2 and an actuating device 3 of the vehicle control system 100 . The actuating part 1 is, for example, a brake handle, a shift handle, or an oil circuit control device, and the actuating device 3 is, for example, a brake device, a transmission device, or an oil circuit control device.

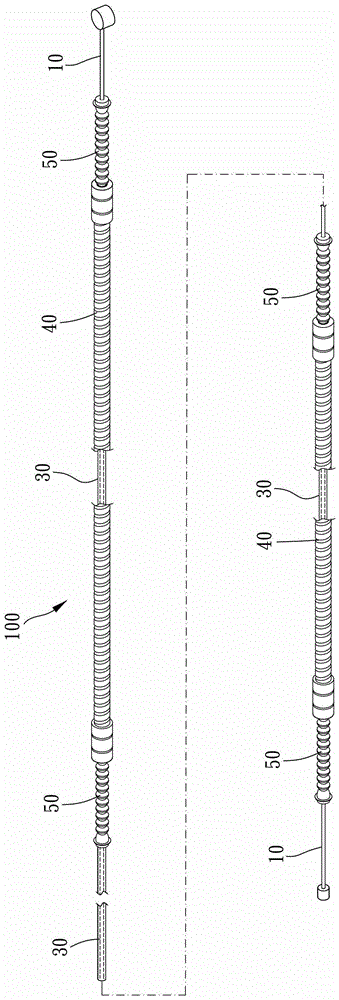

[0028] Please refer further image 3 and Figure 4 , in this embodiment, the vehicle control system 100 includes a central line body 10 , a first casing 20 , a second casing 30 , an oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com