Method of correcting electric angle of motor of new energy automobile

A new energy vehicle, electric angle technology, applied in the estimation/correction of motor parameters, etc., can solve the problems of increasing the calibration process and labor costs, and achieve the effects of high accuracy, reduced labor costs, and reduced human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

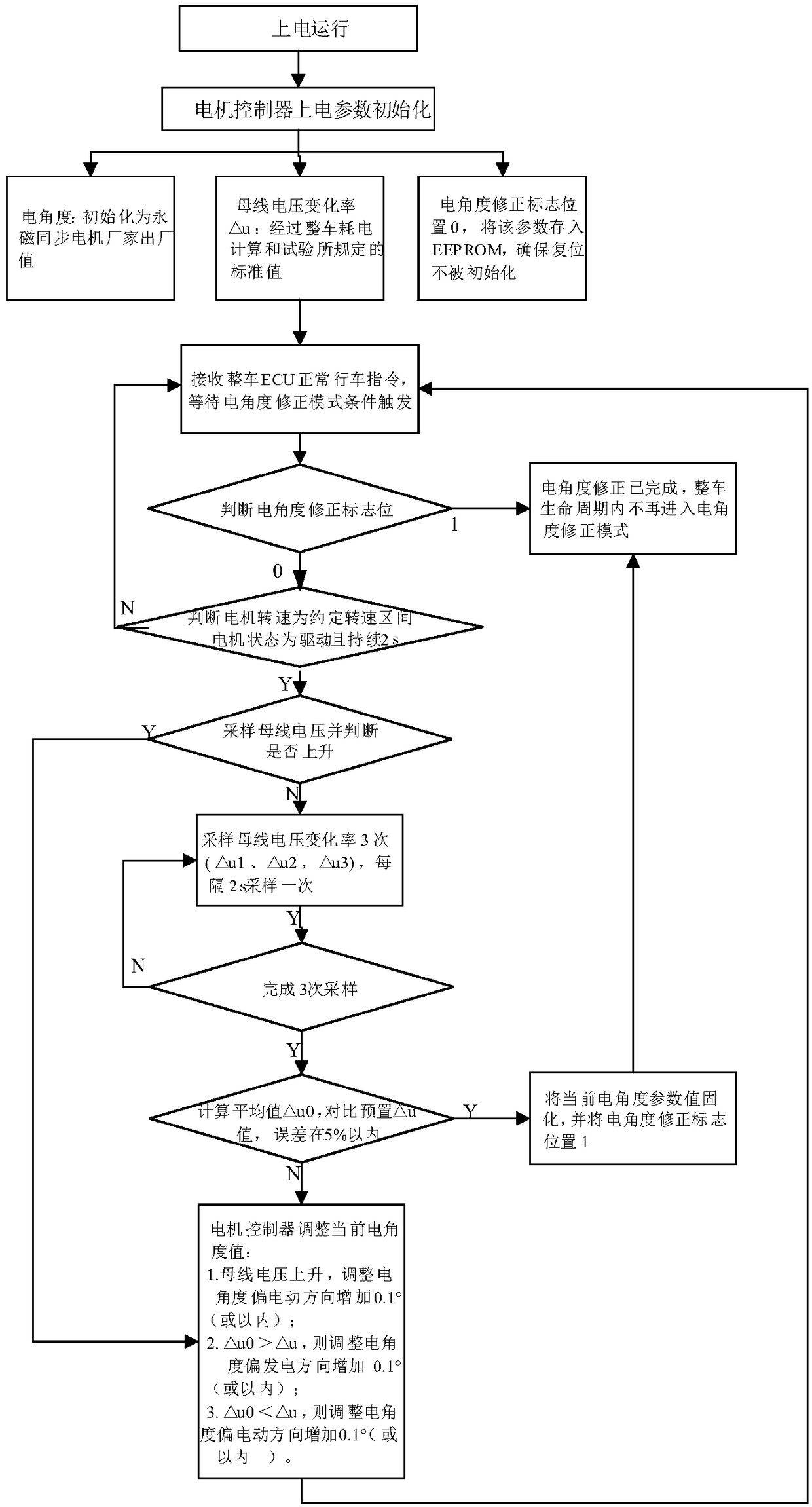

[0020] Such as figure 1 Shown is a flow chart of a new energy vehicle motor electrical angle correction method of the present invention, including the following steps:

[0021] 1. After the vehicle is started, the motor controller is powered on to run, and all parameters are initialized. The initialization value of the motor electrical angle is the parameter given by the manufacturer. The set value △u of the bus voltage change rate of the super capacitor is the test calibration value, and the motor electrical angle The correction flag bit is initialized to 0, and the electrical angle correction flag bit of the motor is stored in EEPROM or other non-erasable memory upon power failure.

[0022] 2. After step 1 is completed, the motor controller enters the normal driving mode, accepts the vehicle ECU command, and waits for the condition to trigger to enter the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com