Electrolyte of lithium-sulfur battery

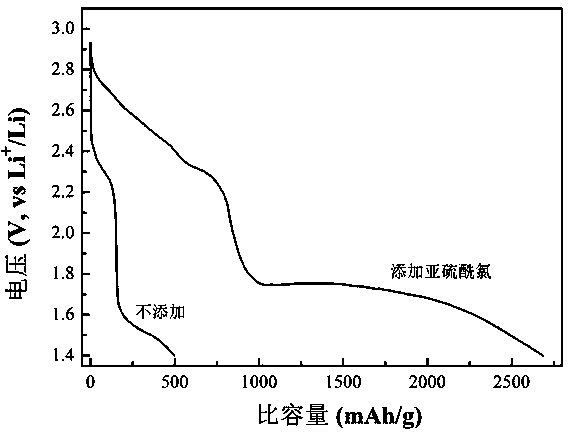

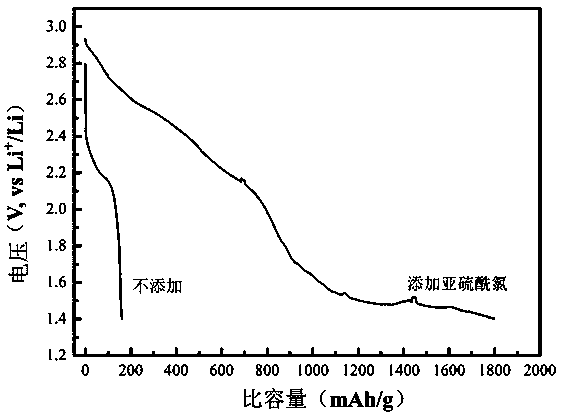

A lithium-sulfur battery and electrolyte technology, which is applied in the new lithium-sulfur battery electrolyte field, can solve the problems of thionyl chloride active additives, etc., and achieves a convenient large-scale industrial production, stable electrochemical performance, and improved energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Material synthesis: Weigh elemental sulfur (sublimed sulfur, 99%, Sinopharm Chemical Reagent Co., Ltd.) and activated carbon (battery grade, Jiangsu Xianfeng Nano Material Technology Co., Ltd.) in a mass ratio of 6:4, transfer them to a ball mill, add A small amount of ethanol (analytically pure) was wet ball milled at 300r / min for 3h, and the ball milled sample was dried in an oven at 60°C for 6h, and then the dried sample was transferred into a polytetrafluoroethylene reactor. In a muffle furnace (DZ47-60, Hefei Kejing Material Technology Co., Ltd.), the temperature was raised to 155°C at a rate of 2°C / min for 12 hours, and cooled to room temperature to obtain the prepared sample containing 60% sulfur.

[0023] Preparation of electrode materials: Weigh the prepared active material, super conductive carbon black, and binder (polyvinylidene fluoride, PVDF) with a mass ratio of 7:2:1, and mix them thoroughly with a mortar , adding an appropriate amount of N-methyl-2-pyrr...

example 2

[0026] Preparation of electrode materials: Weigh the prepared active material, super conductive carbon black, and binder (polyvinylidene fluoride, PVDF) with a mass ratio of 5:4:1, and mix them thoroughly with a mortar , adding an appropriate amount of N-methyl-2-pyrrolidone (NMP), and stirring for 12 h to obtain a homogeneous slurry. The obtained slurry was uniformly coated on the aluminum foil (current collector) with a coater, dried in a vacuum oven at 60 °C for 12 h, and prepared into a circular electrode sheet with a diameter of 10 mm after oil pressure.

[0027] Battery assembly: In order to avoid the influence of factors irrelevant to the experiment on the experimental results, first clean the cleaned button battery, punched electrode sheets and other materials and tools, and then place them in an oven at 60 °C for 6 h. Then quickly weigh the dried pole pieces, and then immediately put them into the glove box together with other tools. The water and oxygen values of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com