Zinc oxide/nickel composite micron rod electrode material and preparation method thereof

A zinc oxide micron, electrode material technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve the problem of low first coulombic efficiency of zinc oxide, incomplete charging reaction, and low cycle performance of zinc oxide and other problems, to achieve the effect of enhancing high-rate charge-discharge performance, improving cycle stability, and small entry and exit resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] (1) The homogeneous precipitation method is used to prepare the precursor by homogeneous precipitation reaction of the mixed solution of zinc nitrate, nickel nitrate and ethylenediamine. The concentration of zinc nitrate in the solution is 0.20 mol / L, and the concentration of nickel nitrate is 0.03 mol / L, the concentration of ethylenediamine is 0.05 mol / L, and the reaction temperature is 65 o C, the reaction time is 1 h.

[0020] (2) Calcining the precursor powder obtained in step (1) in a reducing atmosphere of hydrogen-argon mixture (hydrogen-containing gas fraction 5%), the calcination temperature is 400 o C, the calcination time is 2 h, and the ZnO / Ni composite microrod electrode material is obtained.

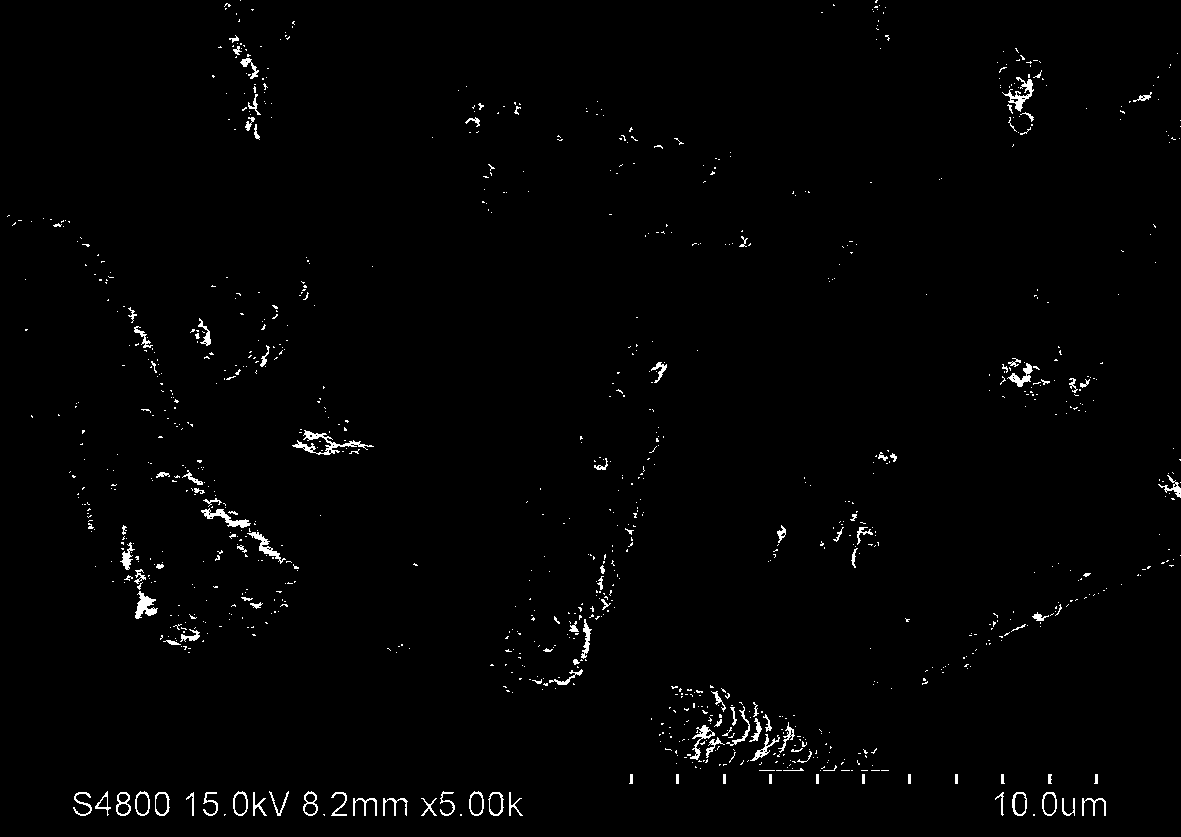

[0021] In the prepared ZnO / Ni composite microrod electrode material, the ZnO microrod was used as the matrix, its length was 10-15 μm, its diameter was 2-3 μm, and its mass fraction was 92%; metal nickel nanoparticles were dispersed in ZnO In the microrod matrix, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com