Cathode slurry material preparation method

A slurry and cathode technology, which is applied in the field of cathode slurry preparation, can solve the problems of increasing the difficulty of mixing and dispersing processes, and achieve the effects of increasing life, increasing energy density, and avoiding settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

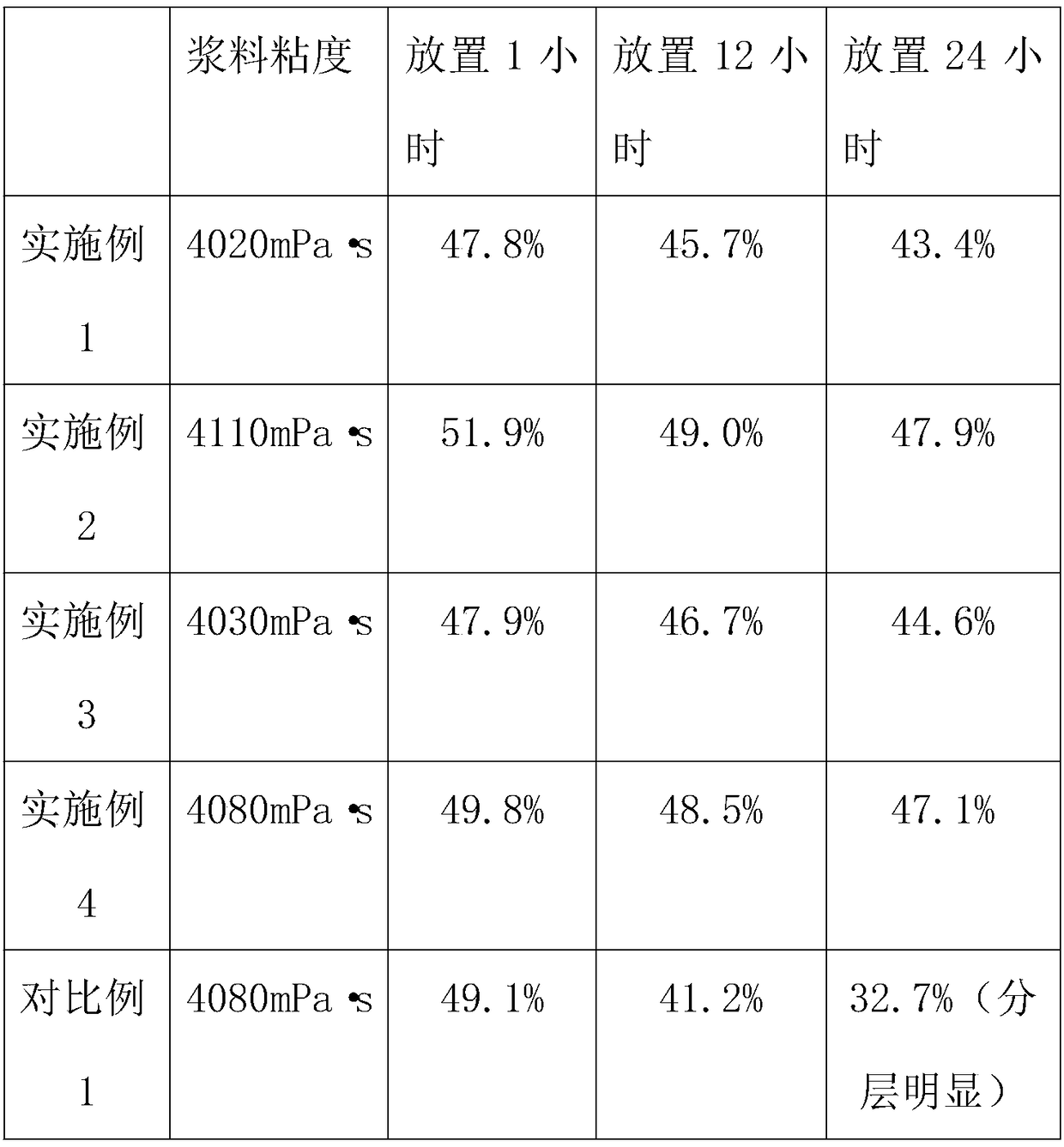

Examples

Embodiment 1

[0026] 1) Provide LiCo 0.97 Al 0.03 o 2 , the LiCo 0.97 Al 0.03 o 2 The particle size is 500nm-1μm; the LiCo 0.97 Al 0.03 o 2 mixed with polyaniline according to the mass ratio of 100:5 and ball milled for 6 hours to obtain polyaniline-coated LiCo 0.97 Al 0.03 o 2 ;

[0027] 2) Add NMP into the first vacuum stirred tank, keep the temperature in the vacuum stirred tank at 5°C, add PVDF and sodium carboxymethyl cellulose into the first vacuum stirred tank, stir for 4 hours, add length For carbon nanotubes of 10 μm, stir for 2 hours, add the product of step 1, stir for 2 hours, add NMP to adjust the solid content of the slurry to 50%, stir for 1 hour, and then vacuumize and stir for 1 hour to obtain the first slurry, wherein the mass ratio, the Polyaniline-coated LiCo 0.97 Al 0.03 o 2 : PVDF: sodium carboxymethyl cellulose: carbon nanotubes = 100:3:2:6;

[0028] 3) Provide LiMnPO 4 f 0.01 / C, where the C content is 3wt%, the LiMnPO 4 f 0.01 / C particle size is ...

Embodiment 2

[0031] 1) Provide LiCo 0.97 Al 0.03 o 2 , the LiCo 0.97 Al 0.03 o 2 The particle size is 1 μm; the LiCo 0.97 Al 0.03 o 2mixed with polyaniline according to the mass ratio of 100:10 and ball milled for 6 hours to obtain polyaniline-coated LiCo 0.97 Al 0.03 o 2 ;

[0032] 2) Add NMP into the first vacuum stirred tank, keep the temperature in the vacuum stirred tank at 5°C, add PVDF and sodium carboxymethyl cellulose into the first vacuum stirred tank, stir for 6h, add length 20 μm carbon nanotubes, stirred for 3 hours, added the product of step 1, stirred for 2-4 hours, added NMP to adjust the solid content of the slurry to 55%, stirred for 1-2 hours, and then vacuumed and stirred for 2 hours to obtain the first slurry, wherein mass ratio, the polyaniline-coated LiCo 0.97 Al 0.03 o 2 : PVDF: sodium carboxymethyl cellulose: carbon nanotubes = 100:5:4:8;

[0033] 3) Provide LiMnPO 4 f 0.01 / C, where the C content is 3wt%, the LiMnPO 4 f 0.01 / C particle size is ...

Embodiment 3

[0036] 1) Provide LiCo 0.97 Al 0.03 o 2 , the LiCo 0.97 Al 0.03 o 2 The particle size is 800nm; the LiCo 0.97 Al 0.03 o 2 mixed with polyaniline according to the mass ratio of 100:8 and ball-milled for 6 hours to obtain polyaniline-coated LiCo 0.97 Al 0.03 o 2 ;

[0037] 2) Add NMP into the first vacuum stirred tank, keep the temperature in the vacuum stirred tank at 8°C, add PVDF and sodium carboxymethyl cellulose into the first vacuum stirred tank, stir for 5h, add length For carbon nanotubes of 15 μm, stir for 3 hours, add the product of step 1, stir for 3 hours, add NMP to adjust the solid content of the slurry to 55%, stir for 2 hours, and then vacuumize and stir for 2 hours to obtain the first slurry, wherein the mass ratio, the Polyaniline-coated LiCo 0.97 Al 0.03 o 2 : PVDF: sodium carboxymethyl cellulose: carbon nanotubes = 100:4:3:7;

[0038] 3) Provide LiMnPO 4 f 0.01 / C, where the C content is 3wt%, the LiMnPO 4 f 0.01 / C particle size is 100nm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com