A bridge deformation monitoring method

A deformation monitoring and bridge technology, applied in the field of bridge engineering, can solve the problems of non-structural deformation, inaccurate measured data, inability to accurately evaluate and truly reflect the deformation of bridges, etc., and achieve the effect of high reliability and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

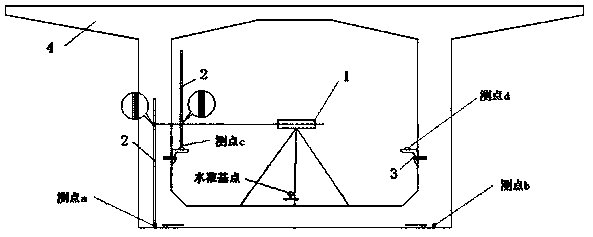

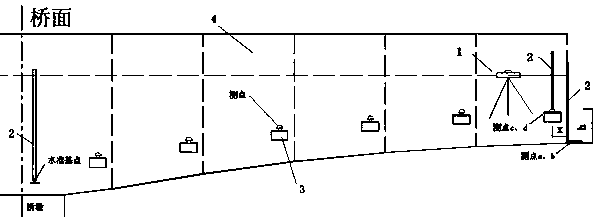

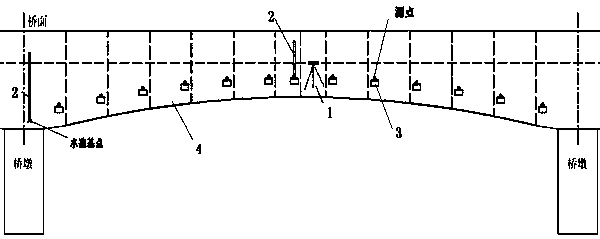

[0051] see figure 1 -6, a bridge deformation monitoring method, especially suitable for bridges with box girder structure (constructed by hanging basket cantilever pouring method, and each segment beam is poured in sections to form the bridge body 4) deformation monitoring method, in the box room of the main girder of the bridge A permanent leveling point is set at the top of the pier, and cross-section measuring points are set inside each segmental beam; use level 1 (preferably a precision level) and supporting leveling rod 2 to measure the distance between the cross-section measuring point and the leveling point in each segmental beam. height difference, so as to calculate the elevation of the cross-section measuring points in each segment beam; by comparing the elevation values of the cross-section measuring points in each segment beam, the deformation of each segment beam can be grasped, so as to realize the deformation of the bridge The monitoring results can also be us...

Embodiment 2

[0083] The monitoring method and device in this embodiment are the same as those in Embodiment 1.

[0084] Taking a super-large bridge as the monitoring object, the bridge structure is composed of 12×45m (prestressed T-beam)+85+2×150+85m (prestressed cantilever cast continuous box girder)+50+2×80+50m (prestressed cantilever Pouring continuous box girder) + 17×25m (prestressed T beam), with a total length of 1704.62m.

[0085] Adopt the monitoring method of the present invention to (85+2×150+85m (prestressed cantilever pouring continuous box girder))+(50+2×80+50m (prestressed cantilever casting continuous box girder)) cantilever casting method to construct the main beam Carry out deformation monitoring;

[0086] Among them (50+2×80+50m (prestressed cantilever cast continuous box girder)), the main girder of the left 17-18# hole (span 80m, the main girder of the bridge spans a total of 20 segmental girders, located on the 17# pier A total of 2 beam sections of 0# on the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com