A dryer suitable for ceramic pipes

A technology for ceramic pipes and dryers, applied in dryers, ceramic products drying, drying and other directions, can solve the problems affecting the overall energy consumption of ceramic enterprises, low ceramic drying efficiency, long ceramic drying time, etc. Drying effect and drying efficiency, improving drying effect and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

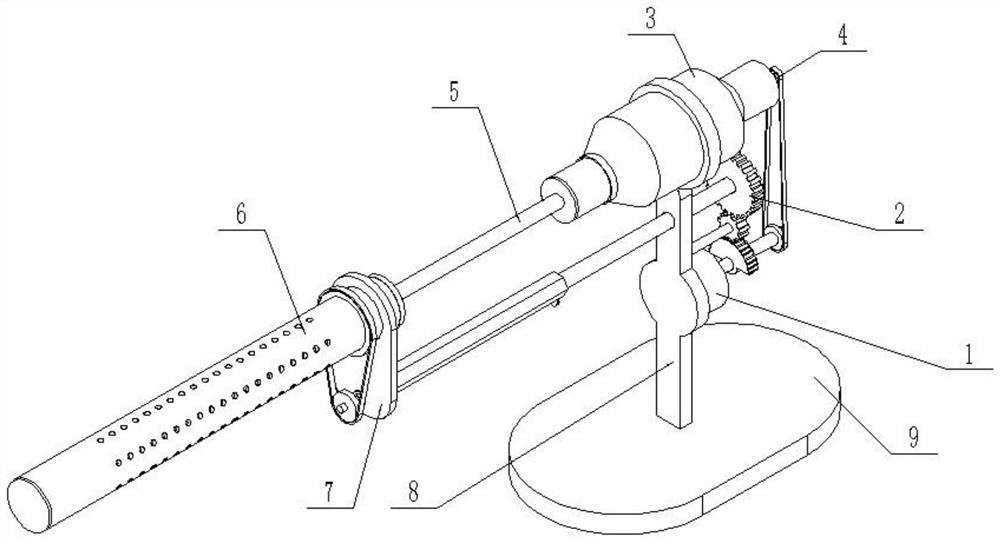

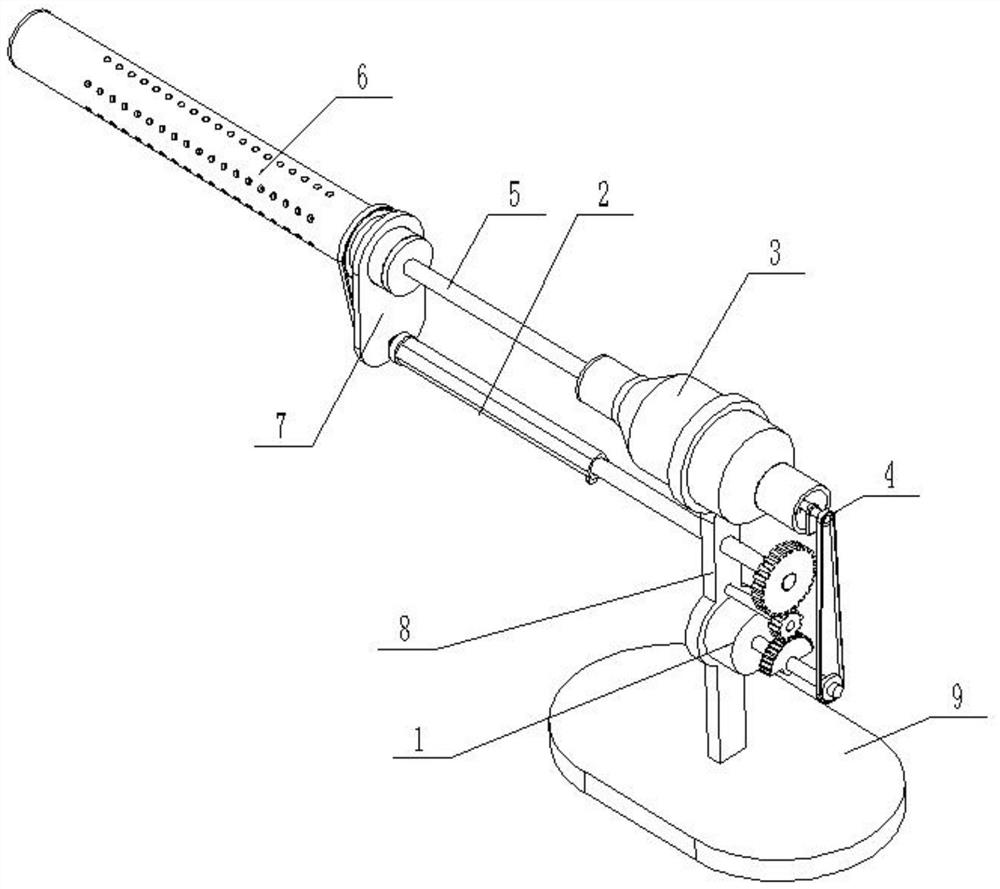

[0041] like Figure 1-13As shown, a dryer suitable for ceramic pipes includes a driving device 1, a transmission wheel 2, a ventilator 3, an exhaust fan 4, an air guide pipe 5, a rotating air pipe 6, a movable frame plate 7, and a vertical frame plate 8 And base plate 9, described driving device 1 comprises servomotor 1-1, drive shaft 1-2, half gear 1-3, reduction gear 1-4, axle 1-5 and driving pulley 1-6; The motor 1-1 is fixedly connected to the vertical frame plate 8 through the motor base, and the vertical frame plate 8 is fixedly connected to the base plate 9; the output shaft of the servo motor 1-1 is connected to the drive shaft 1-2 through a coupling; Said driving shaft 1-2 is fixedly connected with half gear 1-3 and driving pulley 1-6, and the axes of driving shaft 1-2, half gear 1-3 and driving pulley 1-6 are collinear; said half gear 1 -3 meshing transmission connection reduction gear 1-4, reduction gear 1-4 is fixedly connected on the wheel shaft 1-5, the axes of ...

specific Embodiment approach 2

[0044] Such as Figure 1-13 As shown, the transmission wheel 2 includes a linkage gear 2-1, a rotating shaft 2-2, a limit slider 2-3, a rotating sleeve 2-4, a stepped shaft 2-5 and a first pulley 2-6; the rotating shaft 2-2. The axes of the rotating sleeve 2-4, the stepped shaft 2-5 and the first pulley 2-6 are collinear, and the linkage gear 2-1 meshes with the reduction gear 1-4; the linkage gear 2 -1 is fixed on one end of the rotating shaft 2-2, the rotating shaft 2-2 is rotatably connected to the vertical frame plate 8 through a bearing with a seat and is provided with axial positioning, and the other end of the rotating shaft 2-2 is slidingly fitted and connected to the rotating sleeve 2- 4. The inner side of one end is provided with a horizontal chute 2-4-1 on the pipe surface of the rotating sleeve 2-4, and the limit slider 2-3 is slidably connected to the inside of the horizontal chute 2-4-1, and the limit slide The block 2-3 is fixedly connected to the rotating shaf...

specific Embodiment approach 3

[0047] Such as Figure 1-13 As shown, two axial retaining rings 2-5-1 are threadedly connected to the stepped shaft 2-5, and the two axial retaining rings 2-5-1 are arranged at both ends of the vertical frame plate 8 respectively. The arrangement of the axial stop ring 2-5-1 on the stepped shaft 2-5 can prevent the stepped shaft 2-5 from being separated from the movable frame plate 7, and play a role of limiting and positioning the stepped shaft 2-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com