Exhaust manifold structure for improving engine cold start emission

An exhaust manifold and cold-start technology, applied in the field of auto parts, can solve the problem that the efficiency conditions of the three-way catalyst are difficult to meet, and achieve the effects of low heat loss, increased flow rate, and rapid preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

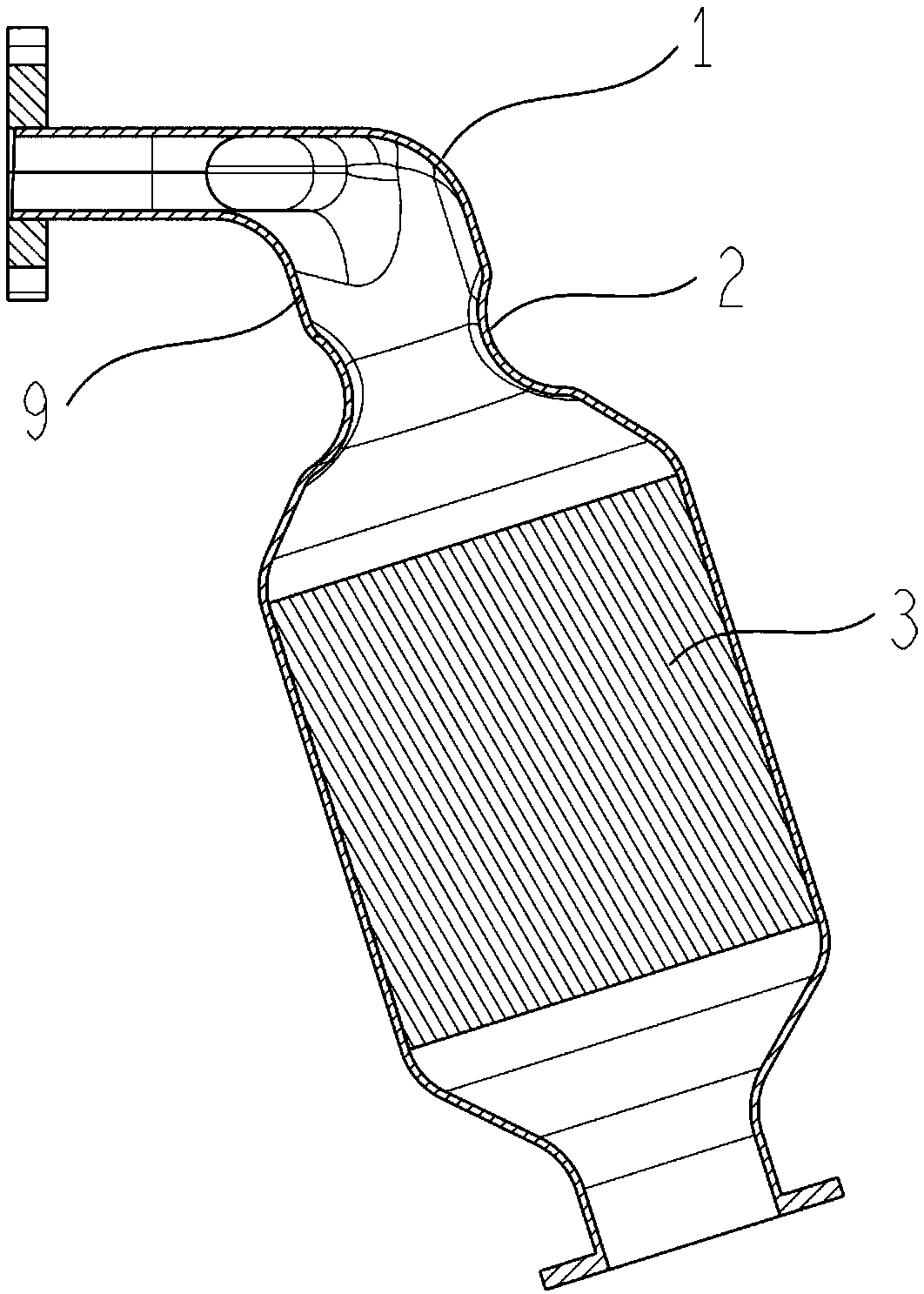

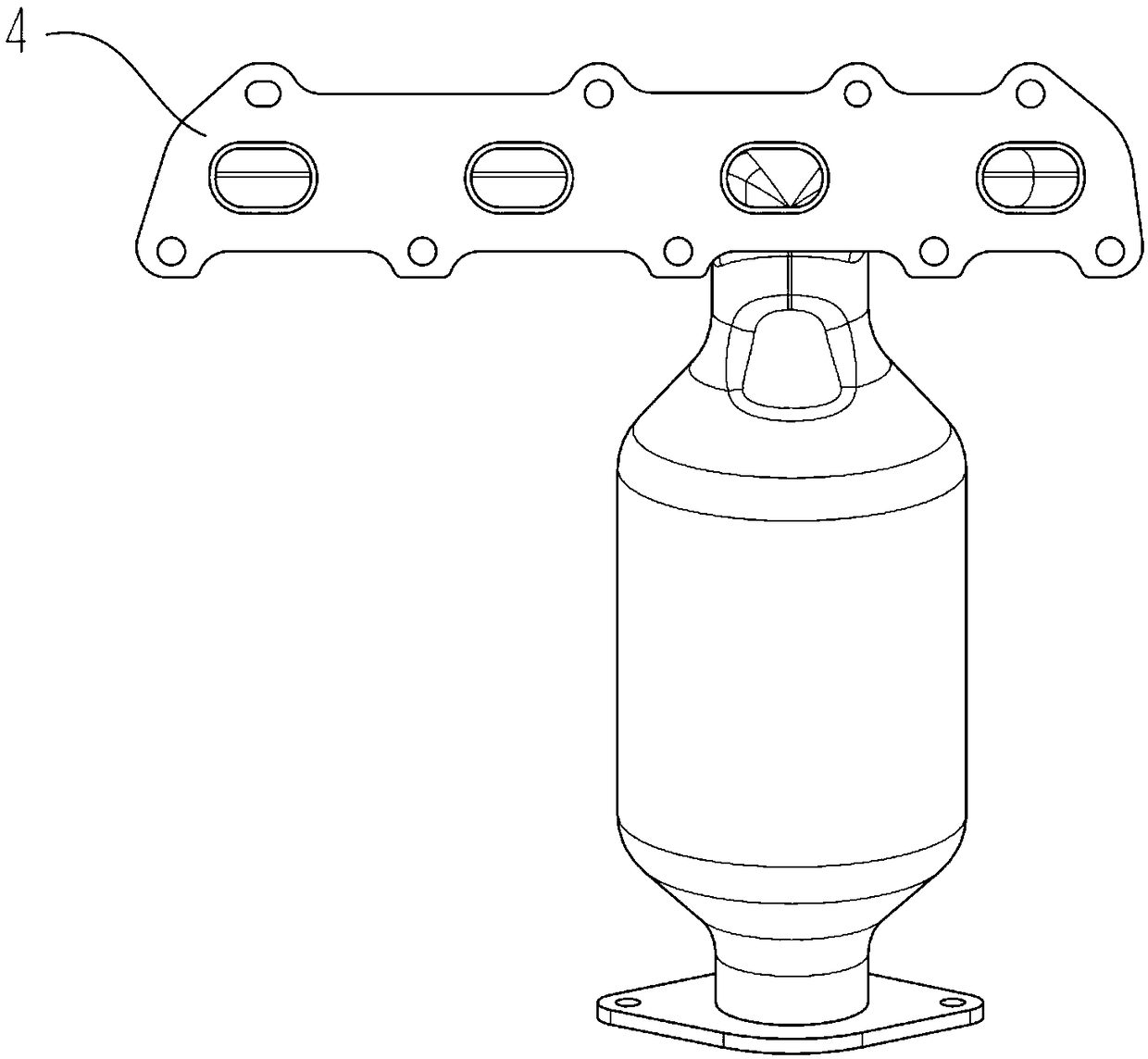

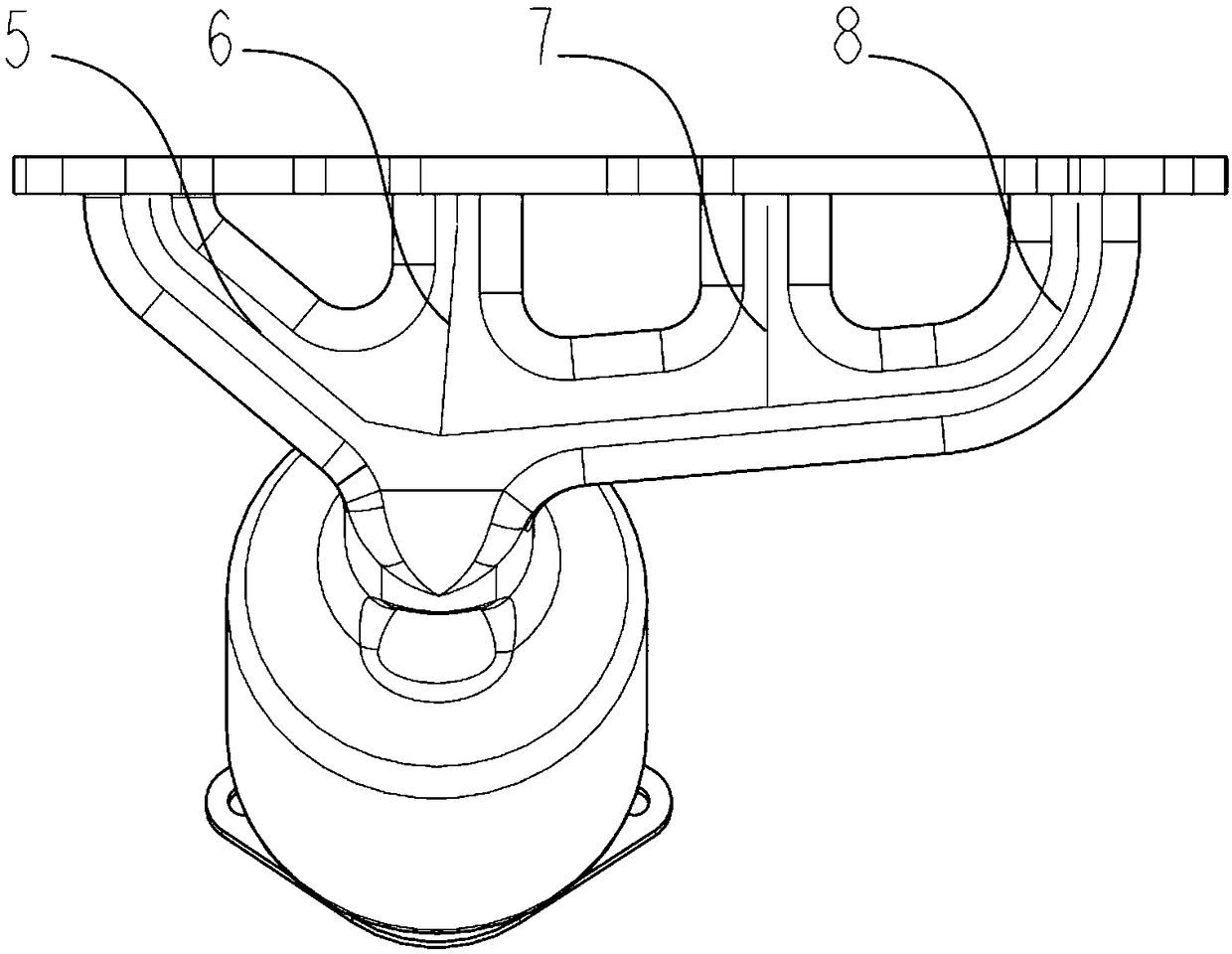

[0027] The diameter of the semicircular arc of the waist circle of the radial section of the first exhaust manifold, the second exhaust manifold, the third exhaust manifold and the fourth exhaust manifold is 19mm, and the waist circle connecting two The length of the two parallel lines at the ends of the semicircle is 31mm, the angle between the centerline of the first exhaust manifold inlet 5 and the centerline of the second exhaust manifold inlet 6 is 55°, the third row The included angle between the centerline of the gas manifold inlet 7 and the centerline of the fourth exhaust pipe inlet 8 is 85°, and the height of the raised structure 2 along the axial direction of the exhaust manifold inlet connecting transition section 9 is 40 mm. The structure 2 has a radial width of 31mm along the inlet of the exhaust manifold connecting the transition section 9, and the diameter of the catalytic converter carrier 3 is 115mm. This embodiment has been verified by experiments. Compared ...

Embodiment 2

[0029] The diameter of the semicircular arc of the waist circle of the radial section of the first exhaust manifold, the second exhaust manifold, the third exhaust manifold and the fourth exhaust manifold is 16mm, and the waist circle connects two The length of the two parallel lines at the ends of the semicircle is 29mm, the angle between the centerline of the first exhaust manifold inlet 5 and the centerline of the second exhaust manifold inlet 6 is 52°, the third row The included angle between the centerline of the gas manifold inlet 7 and the centerline of the fourth exhaust manifold inlet 8 is 82°, and the height of the raised structure 2 along the axial direction of the transition section 9 connected to the inlet of the exhaust manifold is 39mm. The radial width of the starting structure 2 along the inlet of the exhaust manifold connecting the transition section 9 is 29 mm, and the diameter of the catalytic converter carrier 3 is 112 mm. This embodiment has been verified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com