Temperature difference control method for quick cooling or quick starting of turbine

A rapid start-up and temperature difference control technology, which is applied in the direction of engine start-up, machine/engine, mechanical equipment, etc., can solve the problems of uncommon use of devices, affecting the life of steam turbines, long residence time, etc., to avoid excessive metal stress and ensure use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

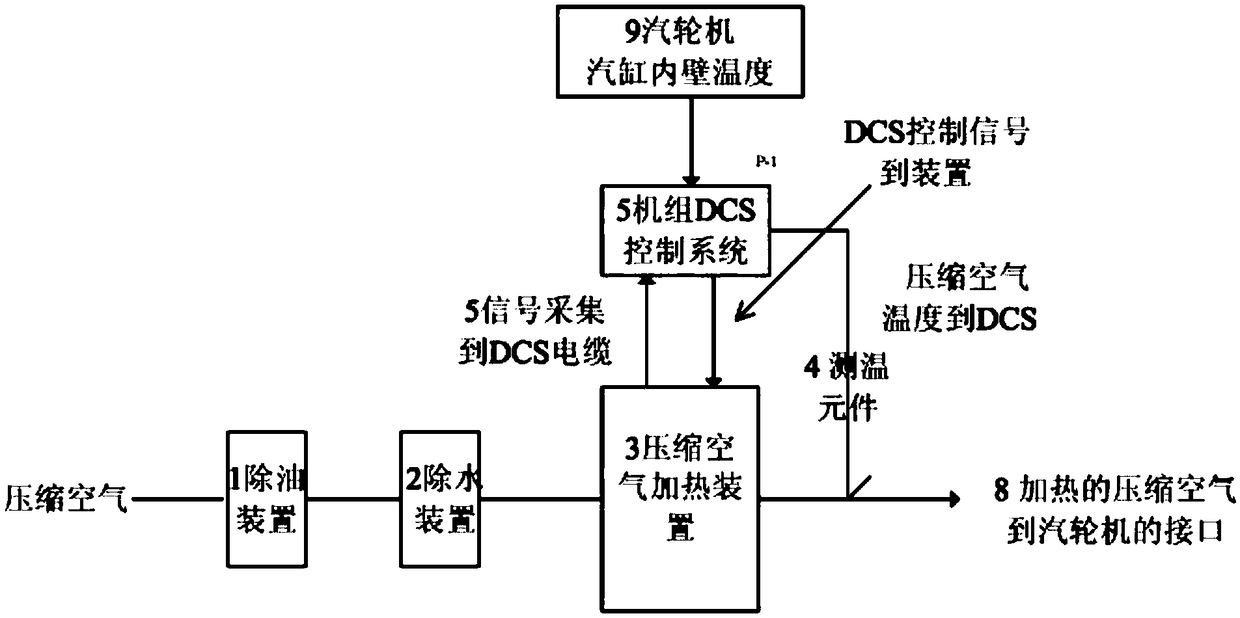

[0028] figure 1 It is a schematic diagram of a quick start device. As shown in the figure, the compressed air enters the inlet 8 of the steam turbine through the oil removal device 1, the water removal device 2, and the compressed air motor heater 3. There is also a temperature measuring element 4 in the figure, and the unit DCS control system 5, steam turbine cylinder inner wall temperature 9.

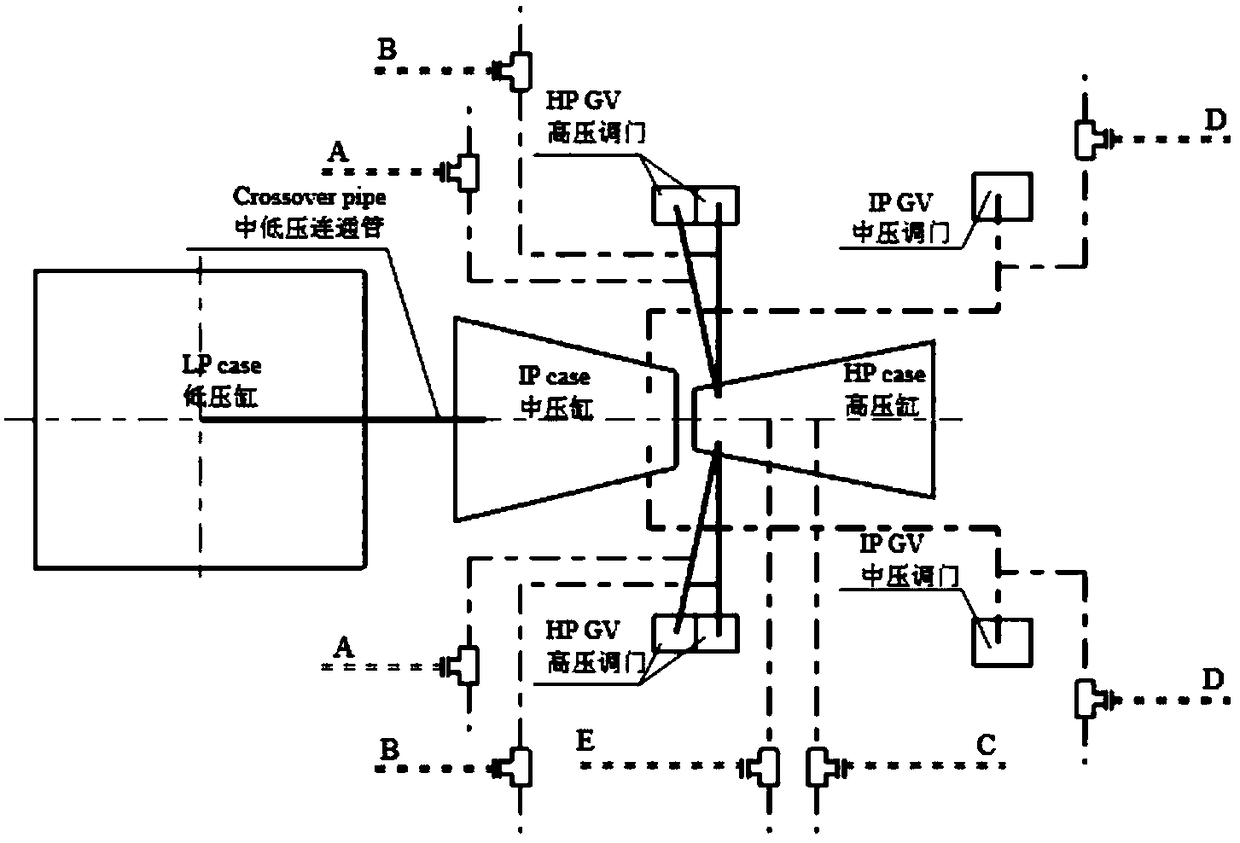

[0029] figure 2 The interface system diagram of the compressed air heated for a certain unit and the steam turbine; as shown in the figure:

[0030] Air inlet: the air inlet port of the high-pressure flow part,

[0031] A: Before the vent valve of the high-pressure steam inlet pipe (steam guide pipe)

[0032] B: Before the steam trap of the high-pressure steam inlet pipe (steam guide pipe)

[0033] C: Before the high-pressure inner cylinder drain valve

[0034] The air inlet port of the flow part of the medium pressure cylinder,

[0035] D: Before the steam trap of the medium p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com