Multidirectional reinforcing steel connecting device

A technology for connecting devices and steel bars, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of reinforced concrete fracture or peeling, increase the difficulty of construction, and local quality hidden dangers, so as to achieve accurate positioning of connections and improve construction progress , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

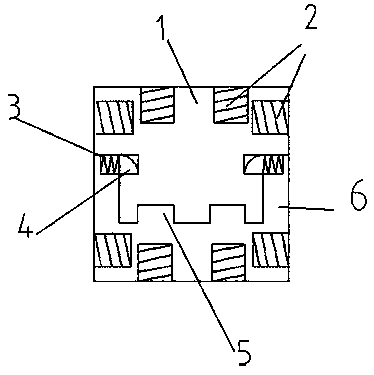

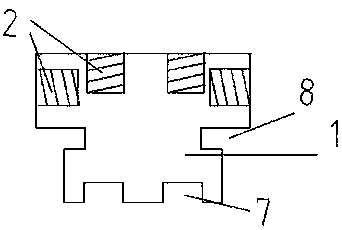

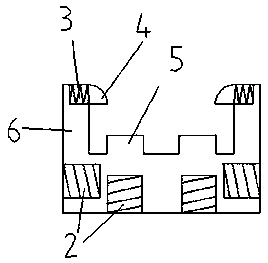

[0021] Such as figure 1 As shown, the multi-directional steel bar connection device of the present invention includes an upper structure 1, a spring member 3, a rigid body 4, a protruding cylinder 5, a lower structure 6 and an L-shaped groove 8, and two bolts are arranged on the upper surface of the upper structure Holes 2, left, right, front and rear are each provided with a bolt hole 2; the bottom of the superstructure 1 is provided with four cylindrical grooves 7; groove 8; the lower surface of the substructure 6 is provided with two bolt holes 2, and the left, right, front and rear are respectively provided with a bolt hole 2; The L-shaped groove 8 is a splicing body; the upper surface of the lower stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com