Novel camellia oil processing technology and processing device thereof

A technology of processing technology and processing equipment, which is applied in the field of new processing technology of camellia oil and its processing equipment, can solve the problems of incomplete evaporation of organic solvent, substandard quality of extracted oil, uneven and incomplete mixing of bran cake and organic solvent, etc. Achieve the effect of reducing the residual oil rate and increasing the oil lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

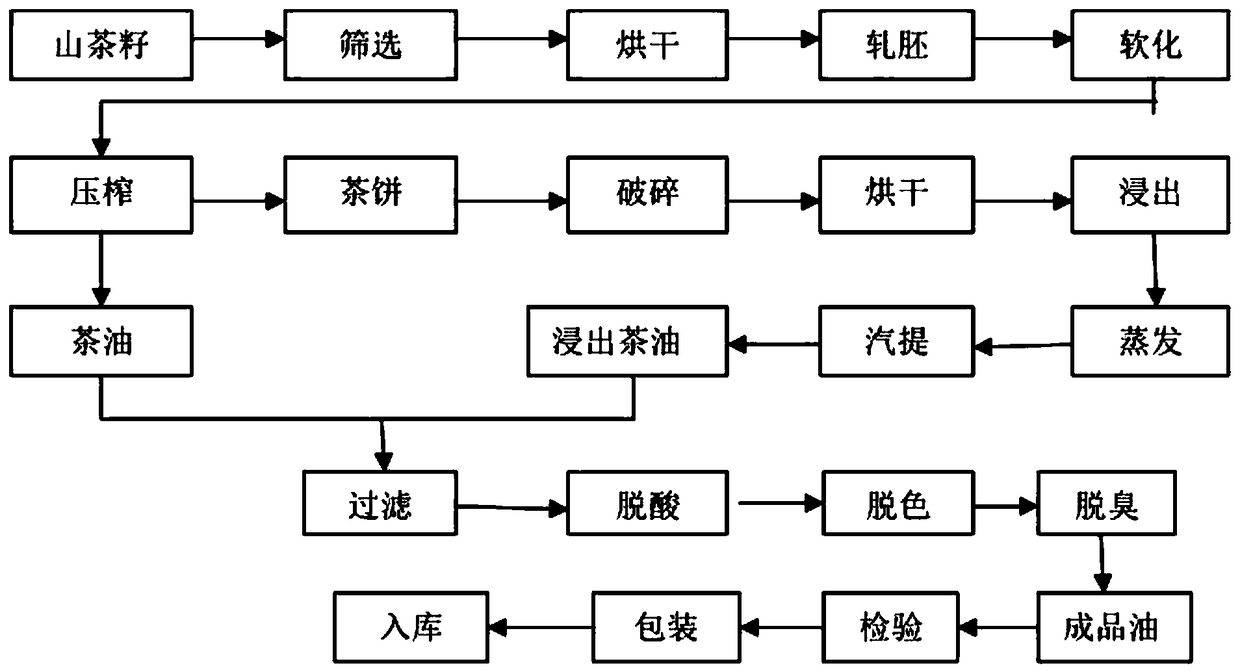

[0041] Such as figure 1 As shown, a new processing technology of camellia oil includes the following steps: a. First, the selected raw materials are processed for the storage of camellia seeds;

[0042] b. After step a is completed, the raw materials are pretreated;

[0043] c. After step b is completed, use the cold press device to perform cold pressing to ensure the oil yield, and food additives need to be added in the cold pressing gap;

[0044] d. After step c is completed, the oil residue is separated by plate and frame filtration;

[0045] e. After step d is completed, use the leaching method to extract the oil cake twice;

[0046] f. After step e is completed, use alkali refining to process the pressed raw tea oil;

[0047] g. After step f is completed, cooperate with deodorization treatment;

[0048] h. After step g is completed, the final packaging is carried out;

[0049] The process of collecting and storing the camellia seed of the raw material in step a includes: screening and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com