Preparation method of pigment titanium dioxide

A titanium dioxide and pigment technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of increasing the solid content of the filter cake and reducing the sintering of titanium dioxide, saving energy consumption and reducing particle sintering. , the effect of reducing natural gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a method for preparing titanium dioxide as a pigment. The method comprises the following steps: a. adding water to metatitanic acid with an iron content of less than 30 ppm for beating to obtain a slurry 1 with a titanium dioxide concentration of 200-450 g / L; b. Add an organic modifier to the slurry 1, then add a treatment agent and stir to obtain a slurry 2; the treatment agent includes potassium salt, phosphoric acid, zinc salt and aluminum salt; b, add an organic modifier to the slurry 1, and then Add a treatment agent and stir to obtain slurry 2; the treatment agent includes potassium salt, phosphoric acid, zinc salt and aluminum salt; the organic modifier is a small molecule with a hydrophilic group and a hydrophobic group or has a hydrophilic The polymer of sexual group and hydrophobic group; c. Squeeze the slurry 2 into a metatitanic acid filter cake, and then obtain the primary product of titanium dioxide through calcination.

[0019] Wher...

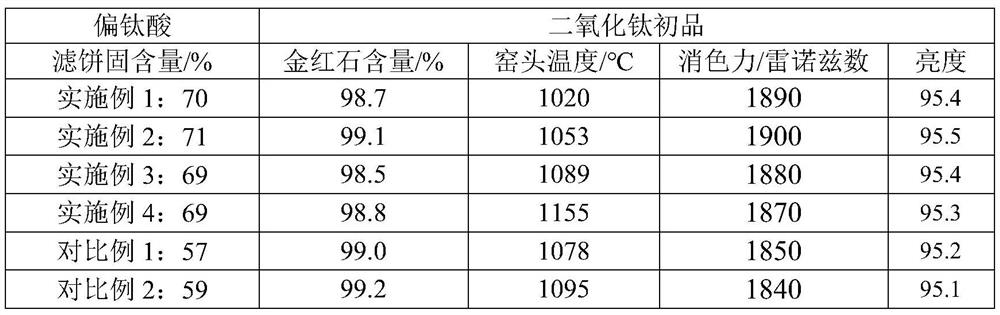

Embodiment 1

[0032] Add water to the metatitanic acid with an iron content of less than 30ppm and make a slurry to obtain a slurry 1 with a titanium dioxide concentration of 300g / L; add 0.2wt% sodium stearate to the slurry 1, stir for 30 minutes, and then add a salt treatment agent for hydrogen oxidation Potassium, phosphoric acid and zinc oxide, control the addition amount, make the K in the slurry 2 O / TiO 2 = 0.60%, P 2 o 5 / TiO 2 =0.15%, ZnO / TiO 2 =0.30% (both by weight ratio), stir for 60min to obtain slurry 2; send slurry 2 to a diaphragm filter press for pressing to obtain a metatitanic acid filter cake, detect the water content of the filter cake, and then pass the filter cake through the lower hopper Send it to a rotary kiln for calcination until the rutile-type titanium dioxide content is 98.7% to obtain the primary product of titanium dioxide. Samples are taken at the kiln head to detect the rutile conversion rate, decolorization power, and brightness of the calcined primary pr...

Embodiment 2

[0034] Add water to the metatitanic acid with an iron content of less than 30ppm and make a slurry to obtain a slurry 1 with a titanium dioxide concentration of 200g / L; add 0.5wt% sodium oleate to the slurry 1, stir for 30min, and then add the salt treatment agent potassium hydroxide , phosphoric acid and zinc oxide, control the amount added so that K in the slurry 2 O / TiO 2 = 0.40%, P 2 o 5 / TiO 2 =0.1%, ZnO / TiO 2 = 0.20% (both by weight ratio), stir for 60min to obtain slurry 2; send slurry 2 to a diaphragm filter press for pressing to obtain a metatitanic acid filter cake, detect the water content of the filter cake, and then pass the filter cake through the lower hopper Send it to a rotary kiln for calcination until the rutile-type titanium dioxide content is 99.1% to obtain the primary product of titanium dioxide. Sampling is carried out at the kiln head to detect the rutile conversion rate, decolorization power, and brightness of the calcined primary product, and rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com