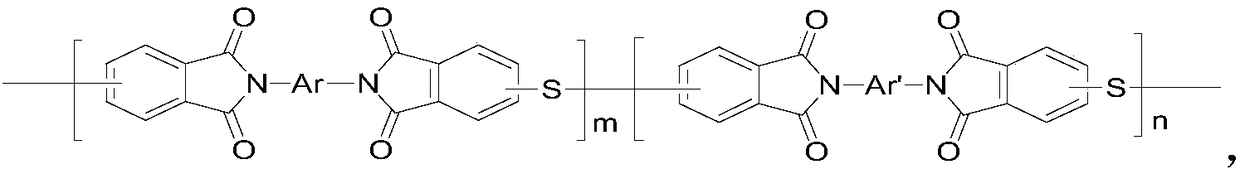

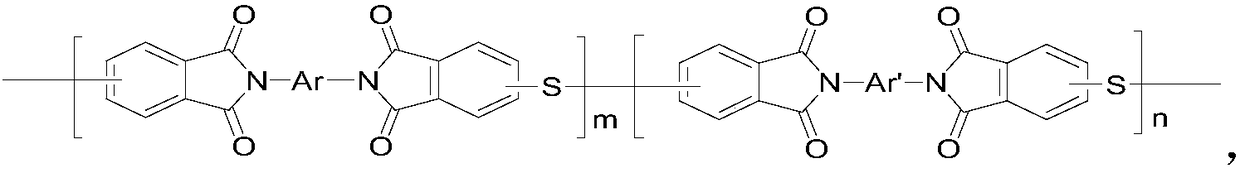

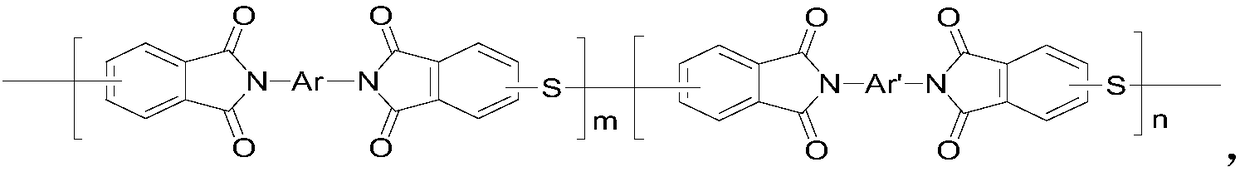

Method for removing low molecular polymers in polythioetherimide resin

A polysulfide imide resin and polymer technology, which is applied in the field of preparation of polysulfide imide resin, can solve the problem that the impact strength of the material is greatly affected, the physical and mechanical properties of the material are greatly affected, and there is no low-molecular polymerization. material and other problems to achieve the effect of improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Add 200g of polythioetherimide resin A with an intrinsic viscosity of 0.35dl / g into 2000ml of reaction flask replaced with nitrogen three times, add 800ml of DMAC, start stirring and heat to 60°C until the resin is completely dissolved into a transparent solution , stop heating and keep stirring. When the temperature drops below 40°C, add toluene slowly under rapid stirring. After adding a certain amount, resin will slowly precipitate. At this time, the precipitated resin is a resin with a relatively high molecular weight. Stop adding when nearly 400ml of toluene is added. Blowing, and suction filtration. The filter cake was washed 4 times with ethanol to remove toluene and residual DMAC, washed 2 times with distilled water to remove residual ethanol, and then dried in a hot air circulation oven at 180°C for 4 hours. The intrinsic viscosity of resin A after testing was 0.38dl / g. It shows that the method of the present invention can effectively improve the molecular we...

Embodiment 2

[0056] Add 200 g of the polythioetherimide resin A with an intrinsic viscosity of 0.35 dl / g in Example 1 into a 2000 ml reaction flask replaced with nitrogen three times, then add 800 ml of DMAC, start stirring and add to 60°C until the resin is completely dissolved After forming a transparent solution, stop heating and keep stirring. When the temperature drops below 40°C, add toluene slowly under rapid stirring. After adding a certain amount, resin will slowly precipitate. The resin precipitated at this time is a resin with a relatively high molecular weight. Stop adding when 500ml of toluene is added. Blowing, and suction filtration under nitrogen protection. The filter cake was washed 4 times with ethanol to remove toluene and residual DMAC, then washed 2 times with distilled water to remove residual ethanol, and then dried in a hot air oven at 180°C. The intrinsic viscosity of the tested resin after drying was 0.36dl / g.

[0057] From the test results of Example 1 and Exa...

Embodiment 3

[0059] Add 200 g of polythioetherimide resin A with an intrinsic viscosity of 0.35 dl / g in Example 1 into a 2000 ml reaction flask replaced with nitrogen three times, add 800 ml of DMSO, start stirring and heat to 60°C until the resin is completely dissolved into After a clear solution, stop heating and keep stirring. When the temperature drops below 40°C, add toluene slowly under rapid stirring. After adding a certain amount, the resin will slowly precipitate out. At this time, the precipitated resin is a resin with a relatively high molecular weight. Stop adding when 500ml of pro-xylene is added. Blowing, and suction filtration under nitrogen protection. The filter cake was washed 4 times with ethanol to remove o-xylene and residual DMSO, then washed 2 times with distilled water to remove ethanol, and then dried in a hot air oven at 180°C. The intrinsic viscosity of the tested resin after drying was 0.39dl / g. It shows that the method of the present invention can effectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com