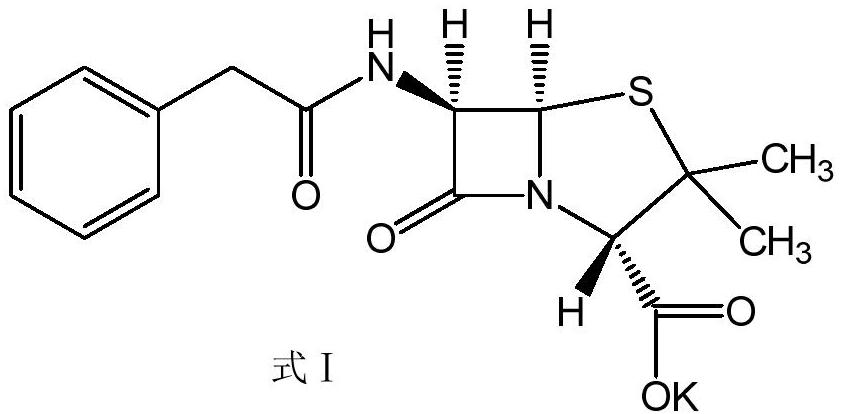

A kind of preparation method of penicillin potassium reference substance

A technology for penicillin potassium and reference substance, which is applied in the field of preparation of penicillin potassium salt reference substance, can solve the problems of high energy consumption and the like, and achieves the effects of high content, simple preparation device and good crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of penicillin fermented liquid of the present invention is as follows:

[0025] Cryotube (25°C spore culture for 7 days)----inclined mother bottle (25°C spore culture for 7 days)----millet spores (26°C seed culture for 56 hours)----first-class seed culture solution (27 ℃ seed culture for 24 hours) ----- secondary seed culture liquid (26.5 ℃ fermentation for 7 days) -- fermented liquid (110000U / ml).

[0026] Among the present invention, the production method of penicillin potassium intermediate is as follows:

[0027] The penicillin fermented liquid is filtered, and with a concentration of 10wt% sulfuric acid solution, 2wt% demulsifier solution (200ml / billion filtrate), butyl acetate (the volume ratio of fermented liquid and butyl acetate is 3:1) to adjust the pH to be 1.8~ 2.2, Centrifuge and separate the phases to obtain a butyl acetate extract, add 33% potassium carbonate aqueous solution to the primary butyl acetate extract for extraction, obt...

Embodiment 1

[0028] The preparation of embodiment 1 penicillin potassium salt reference substance

[0029] Prepare 240 mL of purified water and 20,000 mL of n-butanol cooled to about 5°C.

[0030] Weigh 220.0g of penicillin potassium intermediate into a 5000mL beaker, add 240mL of cooled purified water, stir and dissolve to obtain 400-500ml of penicillin potassium aqueous solution, then add 4000mL of n-butanol cooled to 5°C, and pour the solution into a 25L small test In the crystallization tank, the refrigerating machine circulates and cools at about 5°C, stirs, and slowly feeds (4 liters / hour) cooled n-butanol 14000ml, and the crystallization ends. Filter, wash twice with n-butanol (1000mL / time), top wash twice with 380mL ethyl acetate, drain, and vacuum dry at 60°C for 4 hours to obtain 177.8g of penicillin potassium reference substance.

Embodiment 2

[0031] The preparation of embodiment 2 penicillin potassium salt reference substance

[0032] Prepare 240 mL of purified water cooled to about 5°C and 20,000 mL of n-butanol.

[0033] Weigh 220.0g of penicillin potassium intermediate in a 10000mL beaker, add 240mL of cooled purified water, stir and dissolve, then add 5000mL of cooled n-butanol, pour the solution into a 25L small test crystallization tank, and cool it in a refrigerating machine Stir at about 5°C, slowly add (4 liters / hour) 13000ml of cooled n-butanol, and the crystallization ends. Filter, wash twice with n-butanol (1000mL / time), top wash with 380mL ethyl acetate, drain, and vacuum dry at 60°C for 4 hours to obtain 181.8g of penicillin potassium reference substance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com