Method for preparing N-acetylneuraminic acid hydrate by adjusting hydrogen ion concentration of solution

A technology of acetylneuraminic acid and hydrogen ions, which is applied in the field of preparing N-acetylneuraminic acid hydrate, can solve the problem of high crystallization cost, and achieve the effects of shortened crystallization time, short crystallization time and low environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this example, the method for preparing N-acetylneuraminic acid hydrate by adjusting the concentration of hydrogen ions in the solution is as follows:

[0023] 1. N-acetylneuraminic acid microbial fermentation broth, after being roughly extracted by sterilization, protein removal, salt removal, decolorization, etc., concentrated to 300g / l, ready to use;

[0024] 2. Add concentrated hydrochloric acid to the concentrated solution of N-acetylneuraminic acid obtained in step 1 to adjust the hydrogen ion concentration of the system to pH 1.0;

[0025] 3. Put the mixed liquid obtained in step 1 to crystallize at a low temperature of 10°C until the crystals are precipitated. After the precipitation, let the crystals mature for 12 hours, wash with pure water, the weight ratio of crystals to pure water is 1:1, and dry at 60°C to obtain N-acetylneuraminic acid dihydrate.

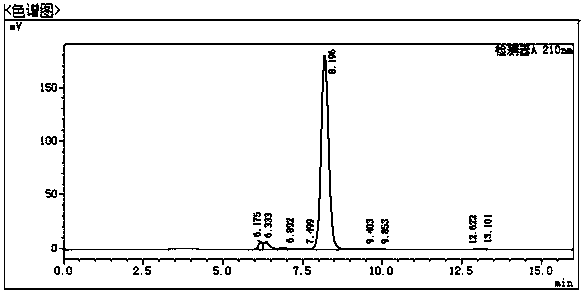

[0026] Detected by high performance liquid chromatography, the content of N-acetylneuraminic acid is 89.2...

Embodiment 2

[0028] In this example, the method for preparing N-acetylneuraminic acid hydrate by adjusting the concentration of hydrogen ions is as follows:

[0029] 1. N-acetylneuraminic acid microbial fermentation broth, after being roughly extracted by sterilization, protein removal, salt removal, decolorization, etc., concentrated to 400g / l, ready to use;

[0030] 2. Add concentrated hydrochloric acid to the N-acetylneuraminic acid aqueous solution obtained in step 1, and adjust the hydrogen ion concentration of the system to pH 1.5;

[0031] 3. Put the mixed liquid obtained in step 1 to crystallize at a low temperature of 4°C until the crystals are precipitated. After the precipitation, let the crystals mature for 24 hours, wash with ethanol, the crystal weight to ethanol weight ratio is 1:1, and dry at 80°C to obtain N- Acetylneuraminic acid dihydrate.

[0032] Detected by high performance liquid chromatography, the content of N-acetylneuraminic acid was 89.0%, the calculated purity...

Embodiment 3

[0034] This implementation is according to embodiment 2 steps, except that the concentrated solution concentration of step 1 is 40g / l, other are all with embodiment 2 steps, the N-acetylneuraminic acid concentrated solution produced by microbial fermentation method is carried out strong acid pH adjustment, finally N-acetylneuraminic acid dihydrate did not crystallize.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com