A kind of low dielectric porous mullite wave-transparent material and preparation method thereof

A technology of porous mullite and wave-transmitting materials, which is applied in the preparation of porous mullite wave-transmitting materials, mullite porous ceramic wave-transmitting materials and its preparation, and can solve the problem of large pore size and uneven distribution of pore diameters in porous ceramics. , Poor foam stability and other problems, to achieve the effect of high moisture resistance, stable foam and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of ceramic slurry: with median particle size D 50 =450nm alumina powder and median particle size D 50 =3μm silicon oxide powder as raw material, ultrapure water as solvent, isobutylene-maleic anhydride copolymer as dispersant, the amount of dispersant added is 0.16wt. Ceramic slurry with a solid content of 55 vol.%;

[0043] (2) Hydrophobically modified dispersant: add 0.28wt.‰ (relative to the mass of the powder) dodecyltrimethylammonium chloride to the slurry, and continue ball milling for 30 minutes to foam;

[0044] (3) Mechanical stirring and foaming: the above-mentioned ceramic slurry is mechanically stirred, and the agitator rotating speed is 800 rev / min, and the mechanical stirring is foamed for 6 minutes;

[0045] (4) Foam slurry solidification and drying: inject the above-mentioned foam slurry into a self-made mold, solidify at room temperature for 12 hours, and demold and dry for 48 hours;

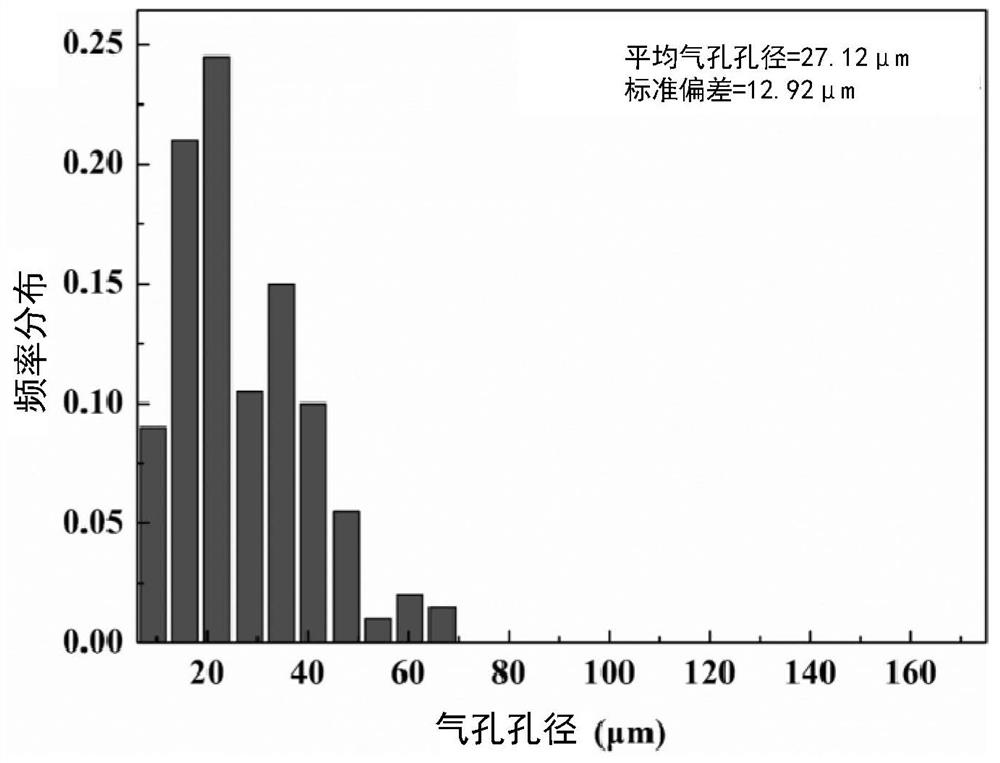

[0046] (5) Sintering: the foamed china is kept at...

Embodiment 2

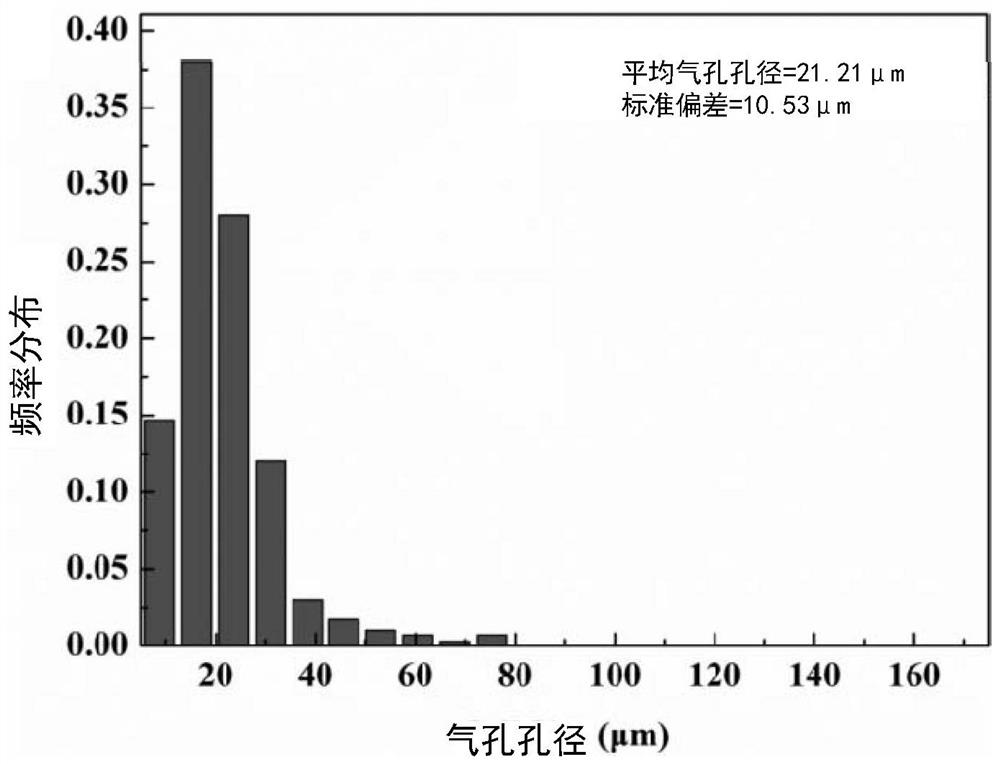

[0048] The preparation process is similar to that of Example 1, except that 0.33 wt.‰ (relative to the mass of the powder) dodecyltrimethylammonium chloride is added to the slurry. The obtained mullite porous ceramics, such as figure 2 As shown in (a) and (b), the average pore diameter in the obtained mullite porous ceramics was 21 μm.

Embodiment 3

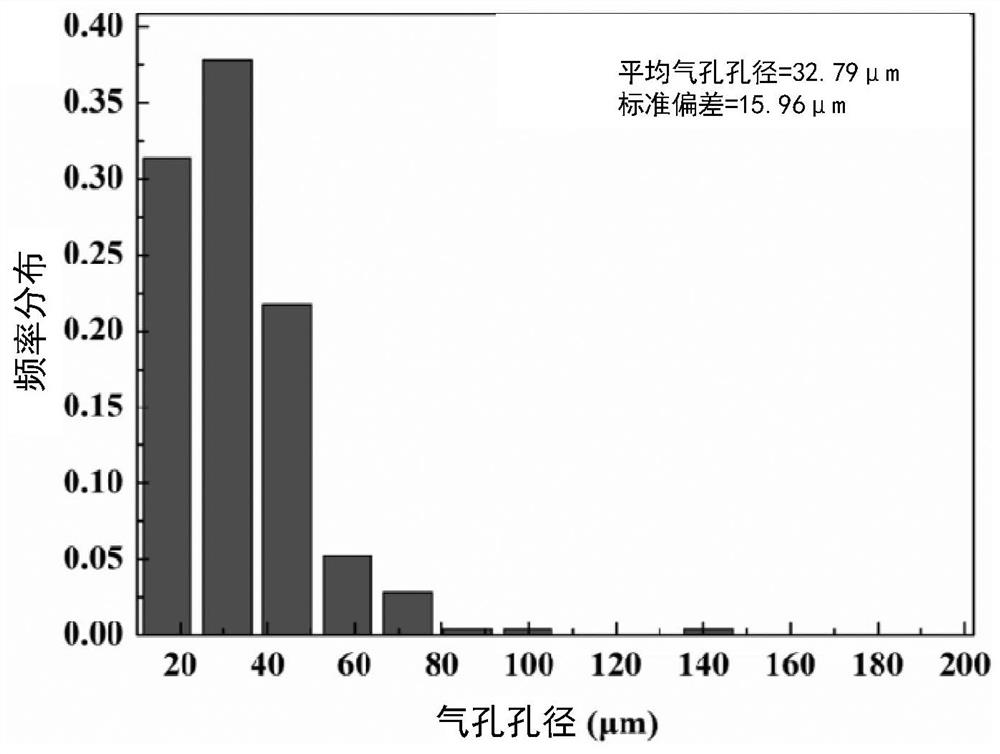

[0050] The preparation process is similar to that of Example 1, except that 0.33 wt.‰ (relative to the mass of the powder) dodecyltrimethylammonium chloride is added to the slurry. The mechanical stirring speed was 1000 rpm, and the stirring was performed for 6 minutes. The average pore diameter of the obtained mullite porous ceramics was 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com