Glass shell structure and preparation method thereof

A glass shell, glass shell technology, applied in chemical instruments and methods, glass/slag layered products, other household appliances, etc., can solve the problems of poor electromagnetic wave diffraction ability, difficult after-sales and maintenance of products, and high cost, etc. Achieve the effect of meeting the needs of 5G antenna millimeter waves, high-end atmospheric consumption and user experience, and reducing the difficulty of disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

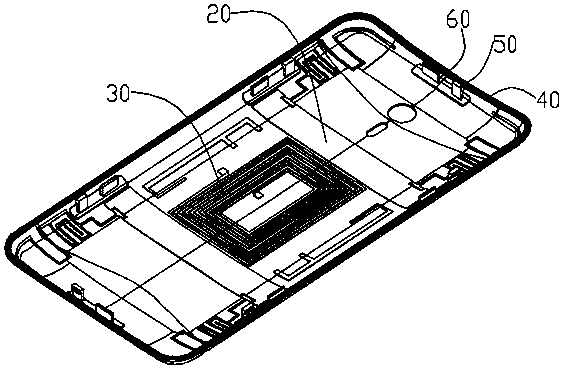

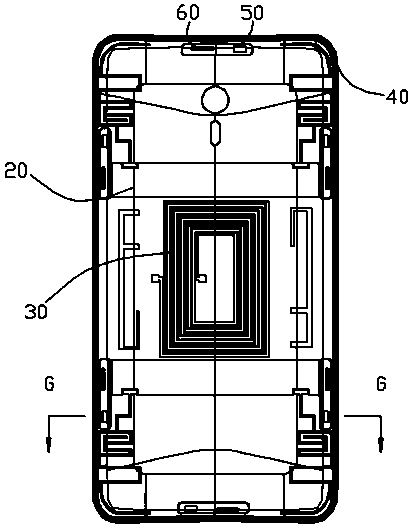

[0075] refer to Figure 1-5 , the present embodiment provides a glass shell structure, including a glass shell 10, a PET composite decorative film 20 attached to the inner surface of the glass shell 10, the PET composite decorative film 20 includes a PET substrate, the One surface of the PET substrate is a hardened surface, and the other surface is a decorative surface; the hardened surface of the PET substrate is bonded to the glass shell, and the decorative surface of the PET substrate is sequentially provided with ink printing layer, UV texture layer, optical coating layer; the optical coating layer of the PET composite decorative film is provided with an LDS antenna 30; the outer periphery of the glass shell structure is also provided with a ring sealing structure 40; the PET composite decoration A buckle structure 50 and a positioning rib structure 60 are also provided on the surface of the diaphragm away from the glass shell.

[0076] refer to Figure 6-13 , the presen...

Embodiment approach

[0087] In the preparation steps of the PET composite decorative film in this embodiment, as a preferred implementation mode: the PET base material can be selected in a larger size, and made into a size of 1*8 products or more, and the thickness of the sheet is about 0.1mm. Subsequent separation by cutting to improve efficiency and reduce costs.

[0088] In the preparation step of the PET composite decorative film in this embodiment, a layer of hardening treatment is carried out on the other surface of the PET base material (the back side of the decorative surface). Generally, it needs to reach a hardness of 1H, so as to avoid scratches on the back of the PET during subsequent processing. protected surface.

[0089] In the preparation step of the PET composite decorative film in this embodiment, ink printing, UV optical texture transfer, optical coating and other decorative treatments are performed on the non-hardened surface of the PET base material after the hardening treatme...

Embodiment 2

[0134] The characteristics of this embodiment are: in the preparation step of the glass shell, the manufacturing method of the glass shell is as follows: heat-bend the flat glass using a graphite mold to obtain the glass shell; the thickness of the flat glass is 0.4-1.5mm.

[0135] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com