Separation and recovery technology for yolk and egg white of crushed duck eggs

A technology for separation and recovery of egg yolk, which is applied in the field of poultry egg processing, can solve the problems of duck egg protein structure damage, no relevant literature reports, and low eggshell resistance strength, so as to avoid economic loss, low adsorption and binding capacity, and strong flavor delicious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

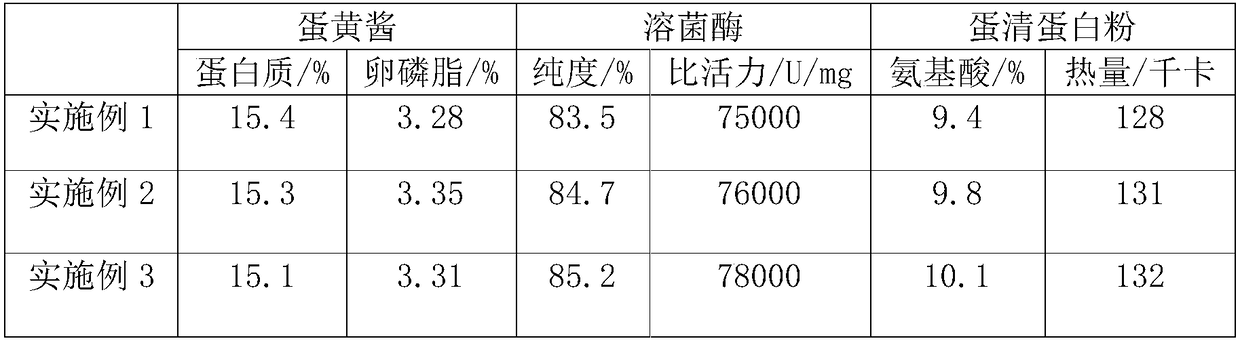

Examples

Embodiment 1

[0022] S1: After picking out the broken eggshells, under the action of a high-voltage pulse auxiliary electric field with a field strength of 30KV and a frequency of 120HZ, slowly pour the duck egg liquid on the surface of a 15-mesh double-layer silk screen, and let it stand naturally until the egg white and egg yolk are separated. When the detachment rate reaches 95%, stop filtering;

[0023] S2: Disperse the separated egg yolk, add 0.08wt% dihydromyricetin, mix well, put in a constant temperature water bath at 68°C for 2 hours, then grind the solidified egg yolk to 160 mesh, add 15wt% olive oil, stir the egg yolk fully Emulsify, then add 1wt% lemon juice, 7wt% white sugar, homogenize with 12MPa pressure, 60rpm rotating speed for 1h, get mayonnaise;

[0024] S3: Add equal weight of distilled water to the separated egg white, homogenize at 20°C with 2MPa pressure and 5rpm speed for 0.5h, then add acetic acid, adjust the pH to 4, stir until the egg white is completely flocculat...

Embodiment 2

[0028] Separation recovery process is with embodiment 1, difference is:

[0029] S1: The field strength and frequency of the high-voltage pulse auxiliary electric field are 35KV and 360HZ respectively, and the mesh number of the screen is 20 mesh;

[0030] S2: The addition amount of dihydromyricetin is 0.14wt%, the water bath temperature is 74°C, the grinding fineness is 180 mesh, the addition amounts of olive oil, lemon juice, and white sugar are 18wt%, 1.5wt%, and 10wt% in sequence, and the homogeneous pressure , the rotational speed is 14MPa, 70rpm respectively;

[0031] S3: The weight of distilled water is twice that of egg white, the homogenization temperature, pressure, and rotation speed are 23°C, 4MPa, and 7.5rpm, respectively, and the edible acid used is citric acid, with a pH of 5.2;

[0032] S4: The transmembrane pressure is 0.14MPa, the molecular weight cut-off of the ultrafiltration membrane is 80KDa, the addition amount of N-acylated chitosan gel is 4wt%, the fl...

Embodiment 3

[0035] Separation recovery process is with embodiment 1, difference is:

[0036] S1: The field strength and frequency of the high-voltage pulse auxiliary electric field are 40KV and 600HZ respectively, and the mesh number of the screen is 25 mesh;

[0037] S2: The addition amount of dihydromyricetin is 0.2wt%, the water bath temperature is 80°C, the grinding fineness is 200 mesh, the addition amounts of olive oil, lemon juice, and white sugar are 20wt%, 2wt%, and 13wt% in sequence, and the homogeneous pressure, The speeds are 16MPa and 80rpm respectively;

[0038] S3: The weight of distilled water is 3 times that of egg white, the homogenization temperature, pressure, and rotation speed are 25°C, 6MPa, and 10rpm, respectively, and the edible acid used is glycolic acid, with a pH of 6.5;

[0039] S4: The membrane penetration pressure is 0.15MPa, the molecular weight cut-off of the ultrafiltration membrane is 100KDa, the addition amount of N-acylated chitosan gel is 6wt%, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com