Branched block polymer for proton exchange membrane, preparation method and application

A proton exchange membrane and polymer technology, applied in the field of branched block type polymers and preparation, can solve the problems of inability to balance proton conductivity and mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

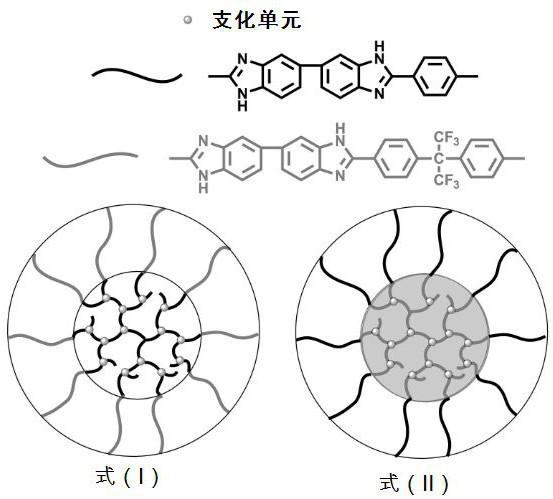

[0056] The present invention also provides a preferred embodiment of the preparation method of the branched block polymer such as formula (I), including the following:

[0057] Step A1. In a protective atmosphere, sequentially add 3,3'-diaminobenzidine, 1,3,5-tris(4-carboxyphenyl)benzene and 1,4-benzenedioic acid to the 130-150°C In polyphosphoric acid (PPA), keep stirring for 1.5-2.5h, then raise the temperature to 165-175°C for pre-polymerization for 20-60min, then raise the temperature to 210-230°C for 40min-1.5h to obtain the intermediate product (Brp-PBI- Am);

[0058] Step B1, cooling the reacted mixture in step A1 to 130-150°C, and then adding 3,3'-diaminobenzidine and 2,2-bis(4-carboxyphenyl)hexafluoropropane in sequence, And keep stirring for 1.5-2.5h, then raise the temperature to 210-230°C for 3-5h;

[0059] Step C1, cooling the reacted mixture in step B1 to 20-40°C, soaking in saturated sodium bicarbonate solution, filtering, and washing the precipitate to obtain...

Embodiment 1

[0071] Example 1 Synthesis of the polymer of formula (I) (branched poly-p-phenylene bibenzimidazole block fluorine-containing polybenzimidazole)

[0072] (1) Install a 100 mL three-necked flask with a condensing device on a magnetic stirrer, and place the flask in an oil bath.

[0073] (2) Add 45 g of polyphosphoric acid into the three-necked flask in a nitrogen atmosphere, raise the temperature to 140 °C, and keep it warm for 2 hours until the magnetron proceeds smoothly under the condition of high rotation speed.

[0074] (3) Add 0.4543 g 3,3'-diaminobenzidine (2.12 mmol), 0.1052 g 1,3,5-tris(4-carboxyphenyl)benzene (0.24 mmol) and 0.2725 g 1 , 4-phthalic acid (1.64 mmol), the molar ratio of the three is 53:6:41.

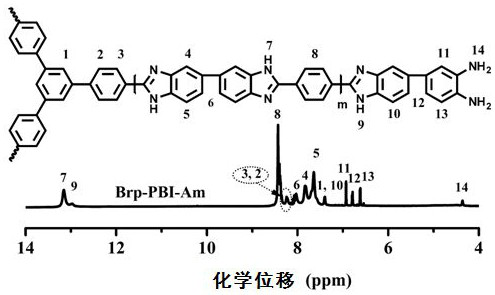

[0075] (4) Stir at 140 °C for 2 h, then heat up to 170 °C for 0.5 h of prepolymerization, and then react at 220 °C for 1 h to obtain the intermediate product Brp-PBI-Am.

[0076] (5) Cool the reacted mixture to 140 °C, add 0.4285 g 3,3'-diaminobenzidine (2 mmol)...

Embodiment 2

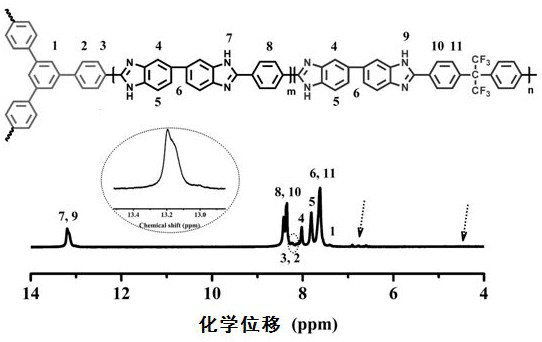

[0080] Example 2 Synthesis of the polymer of formula (II) (branched fluorine-containing polybenzimidazole block poly-p-phenylene bibenzimidazole)

[0081] (1), (2) steps are the same as in Example 1.

[0082] (3) Add 0.4285 g of 3,3'-diaminobenzidine (2 mmol) and 0.3522 g of 1,4-phthalic acid (2.12 mmol) to the three-necked flask in sequence, with a molar ratio of 1:1.06.

[0083] (4) The steps are the same as in Example 1 to obtain the intermediate product p-PBI-Ac.

[0084] (5) Cool the reacted mixture to 140 °C, add 0.4543 g 3,3'-diaminobenzidine (2.12 mmol), 0.1052 g 1,3,5-tris(4-carboxybenzene base) benzene (0.24 mmol) and 0.6433 g 2,2-bis(4-carboxyphenyl)hexafluoropropane (1.64 mmol), the molar ratio of the three is 53:6:41.

[0085]Steps (6), (7), and (8) are the same as in Example 1, and finally a branched fluorine-containing polybenzimidazole block poly-p-phenylene bibenzimidazole polymer (BrF6-PBI-b-p-PBI) is obtained , the yield was 91%, and the degree of branchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com