Photosensitive composition, pattern forming method, cured product and display device

A technology of photosensitive composition and cured product, which is applied in the direction of bonding method, photolithographic process exposure device, photosensitive material processing, etc., to achieve the effect of ensuring high height and good sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

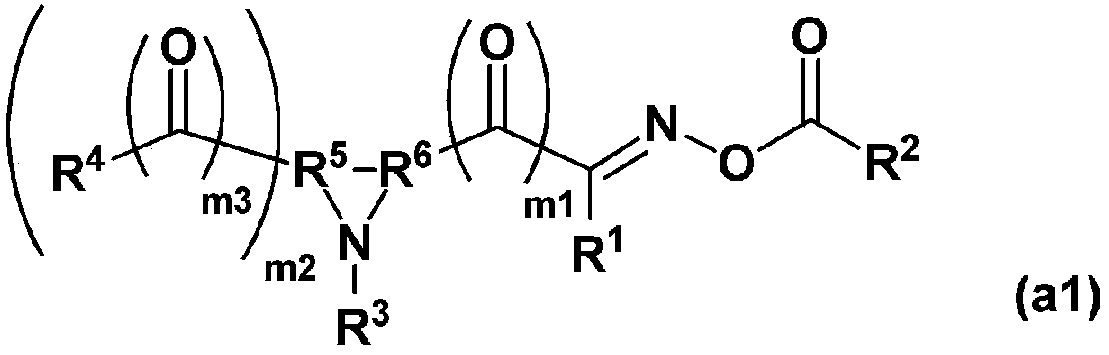

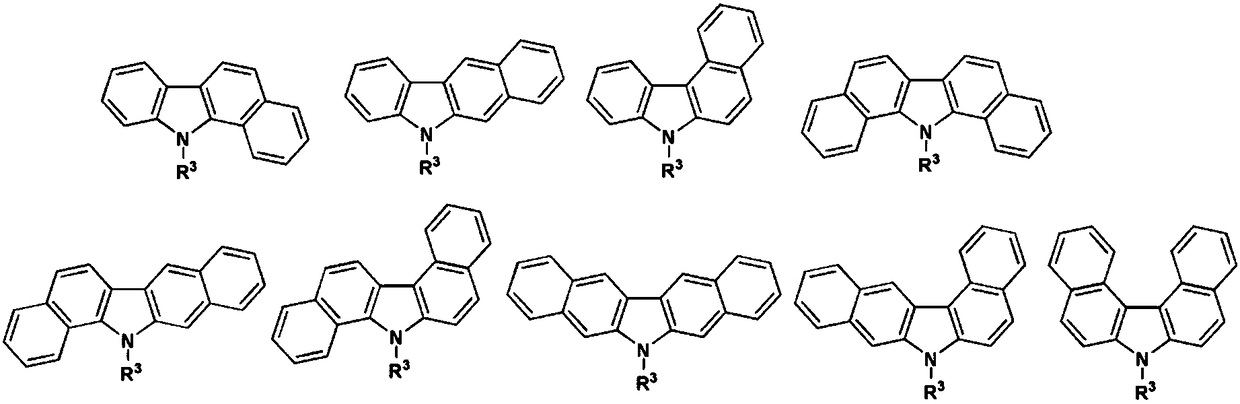

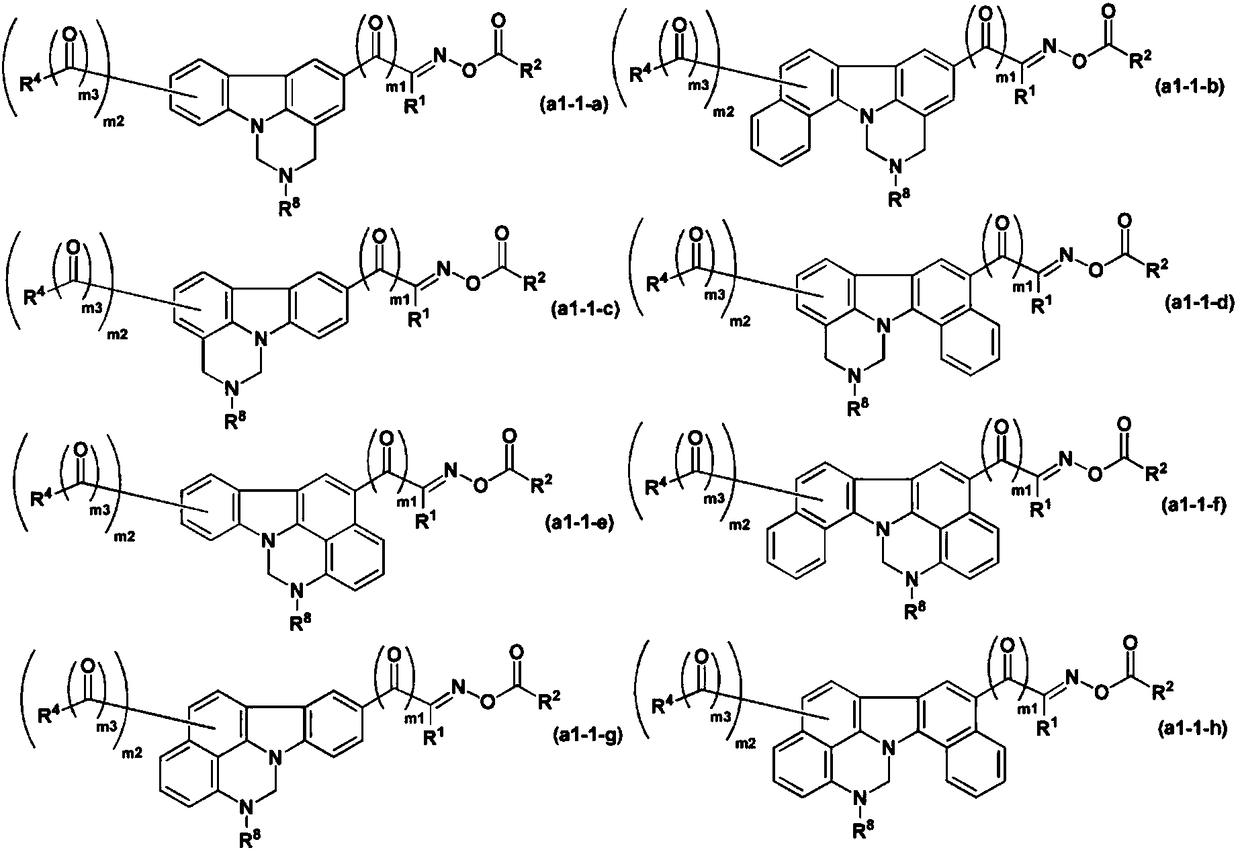

Method used

Image

Examples

preparation example Construction

[0594] "Preparation method of photosensitive composition"

[0595] The photosensitive composition according to the present invention can be prepared by uniformly stirring and mixing the above-mentioned components to dissolve and disperse them uniformly, and then, if necessary, filtering with a filter such as a 0.2 μm membrane filter.

[0596] "Cured product forming method and cured product"

[0597] The method for forming a cured product is the same as the conventional method for forming a cured product using a photosensitive composition except that the above-mentioned photosensitive composition is used.

[0598]The method of forming a cured product using the above-mentioned photosensitive composition is not particularly limited, and may be appropriately selected from conventionally employed methods. The cured product can be formed into a molded product having a desired shape by controlling the shape of the coating film at the time of coating the photosensitive composition an...

Embodiment 1 and comparative example 1~4

[0630] 3 parts by mass of a photopolymerization initiator (A), 38 parts by mass of a photopolymerizable compound (B1), and 62 parts by mass of a resin (B2) were dissolved in an organic solvent so that the solid content concentration was 24 mass % to prepare a photosensitive resin. combination.

[0631] As the photopolymerization initiator (A), the following PI-1, PI-2, and PI-3 were used. The light absorption characteristics of these photopolymerization initiators are shown in Table 1 below. The numerical value of the gram light absorption coefficient of PI-3 in Table 1 is the value at 400 nm.

[0632] [chemical formula 60]

[0633]

[0634] [Table 1]

[0635]

[0636] The kind and quantity of the photoinitiator used in Example 1 and Comparative Examples 1-4 are as described in Table 2 below.

[0637] As the photopolymerizable compound (B1), dipentaerythritol hexaacrylate was used.

[0638] As the resin (B2), an acrylic resin (Mw: 10000) composed of the following st...

Embodiment 2 and comparative example 5

[0668] 5 parts by mass of a photopolymerization initiator (A), 10 parts by mass of a photopolymerizable compound (B1), 32 parts by mass of a resin (B2), 8 parts by mass of carbon black, and 34 parts by mass of a perylene pigment were prepared so that the solid content concentration was 25 mass %. Parts by mass and 6 parts by mass of a dispersant were dissolved and dispersed in an organic solvent to prepare a photosensitive composition.

[0669] As the photopolymerization initiator (A), the aforementioned PI-1 and PI-2 were used. The kind and quantity of a photoinitiator are as described in Table 3. As the photopolymerizable compound (B1), 3 parts by mass of tetraethylene glycol dimethacrylate and 7 parts by mass of dipentaerythritol hexaacrylate were used.

[0670] As the resin (B2), Cardo resin synthesized by the following method was used.

[0671] At first, in the 500mL four-necked bottle, 235g of bisphenol fluorene type epoxy resin (epoxy equivalent weight 235), 110mg of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com