Thulium-doped gain fiber and fiber laser

A technology of gain fiber and fiber, which is applied in the direction of lasers, laser components, cladding fibers, etc., can solve the problems of laser output power improvement, energy absorption unevenness, etc., achieve output beam quality and output power improvement, and prevent thermal lens effect , the effect of reducing light damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

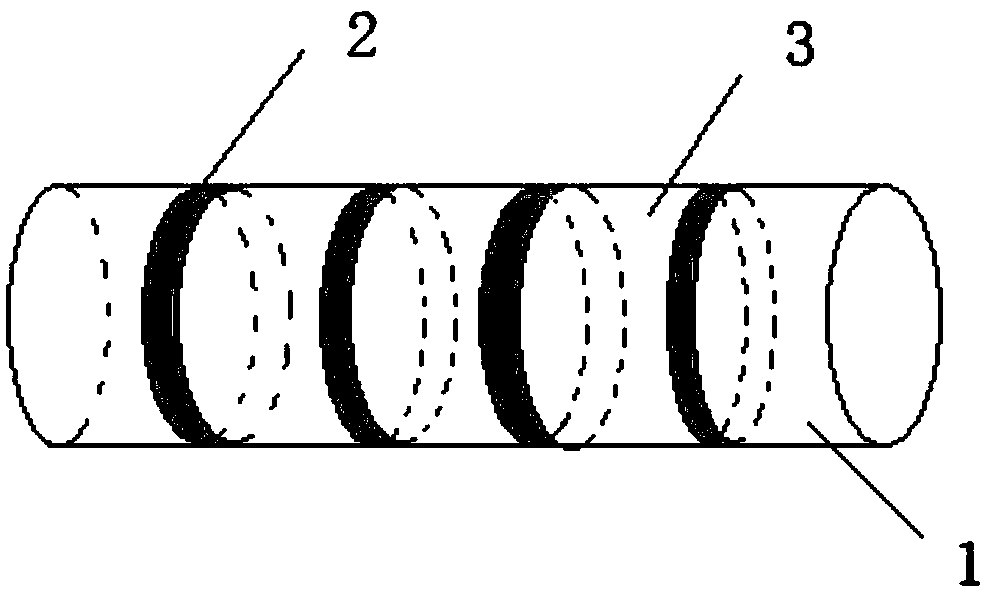

[0046] like figure 1 As shown, the present invention provides a thulium-doped gain fiber, which includes an outer cladding, an inner cladding and a doped core 1, and the doped core 1 is provided with low-doped segments 2 at intervals along the longitudinal direction.

[0047] The length of the low-doped section 2 is 0.01 cm. All low doped segments 2 have the same length.

[0048] The distance between the low-doped segments 2 is 0.5 cm.

[0049] The optical fiber is made of germanate glass. The germanate glass optical fiber has good thermal stability and infrared transparency, high solubility of rare earth ions, and low phonon energy. It is the rare earth doped 2μm laser output. Good base material. Moreover, the germanate glass can realize the effect of high doping of rare earth ions, and the gain effect is good, and the single longitudinal mode output can be realized by shortening the cavity length.

[0050]The molar percentage range of the glass matrix of part 3 other tha...

Embodiment 2

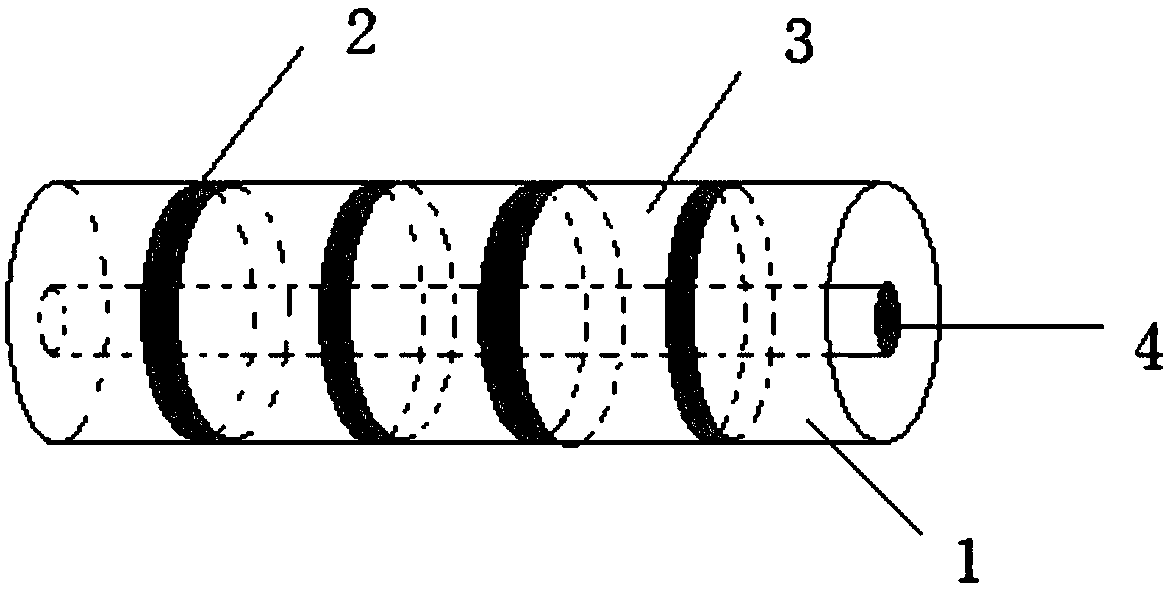

[0073] like figure 2 As shown, the present invention provides a thulium-doped gain fiber, which includes an outer cladding, an inner cladding and a doped core 1, and the doped core 1 is provided with low-doped segments 2 at intervals along the longitudinal direction. A cylindrical low-doped portion 4 is arranged in the center of the fiber core.

[0074] The length of the low-doped section 2 is 0.2 cm. All low doped segments 2 have the same length.

[0075] The distance between the low-doped segments 2 is 10 cm.

[0076] The optical fiber is made of germanate glass. The germanate glass optical fiber has good thermal stability and infrared transparency, high solubility of rare earth ions, and low phonon energy. It is the rare earth doped 2μm laser output. Good base material. Moreover, the germanate glass can realize the effect of high doping of rare earth ions, and the gain effect is good, and the single longitudinal mode output can be realized by shortening the cavity leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com