Test system for failure spatiotemporal evolution of rock in deep complex environment

A technology for complex environments and test systems, applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as signal inaccuracy and acoustic emission signal interference, and achieve the effect of avoiding interference, avoiding disturbance, and improving test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

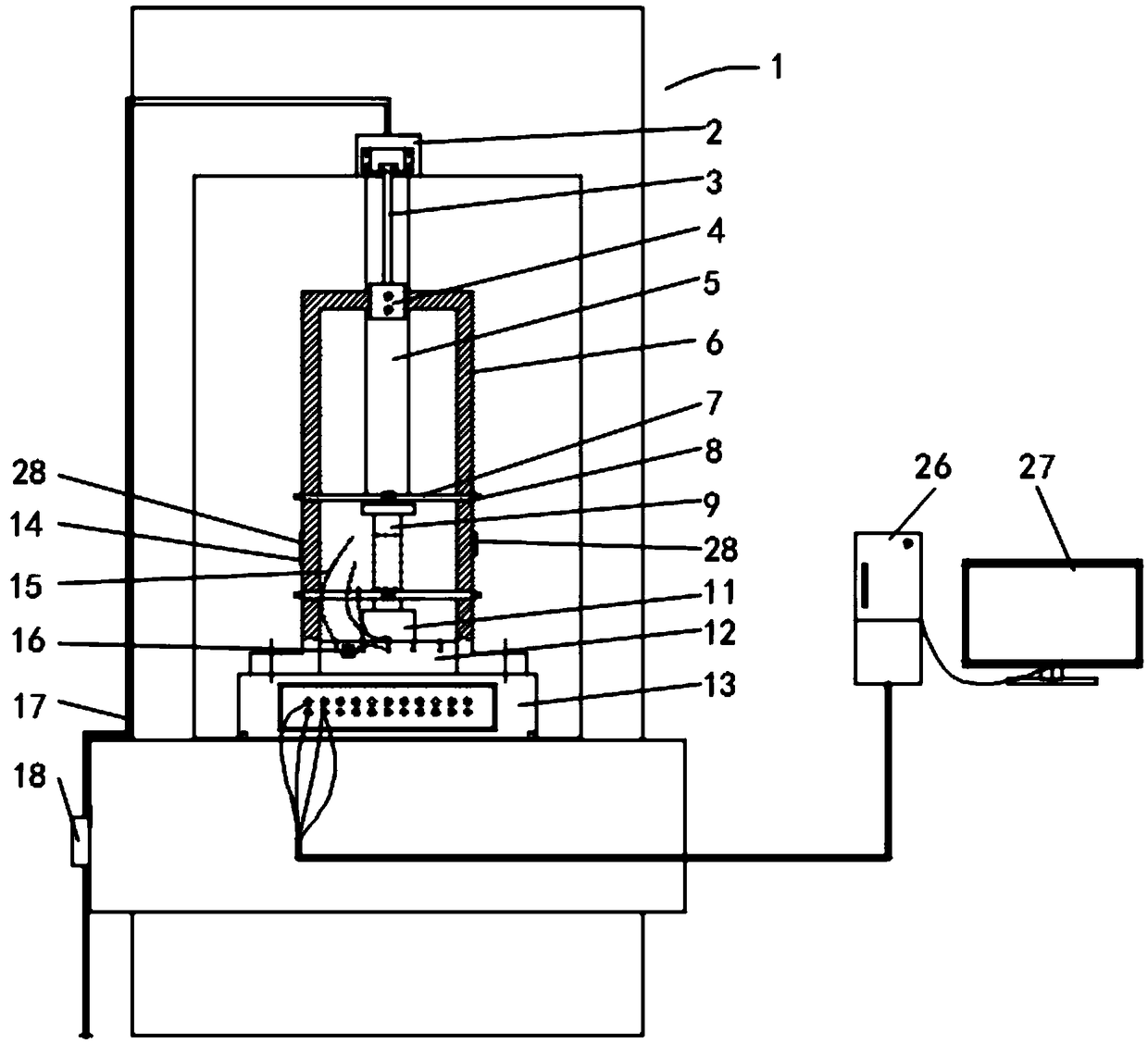

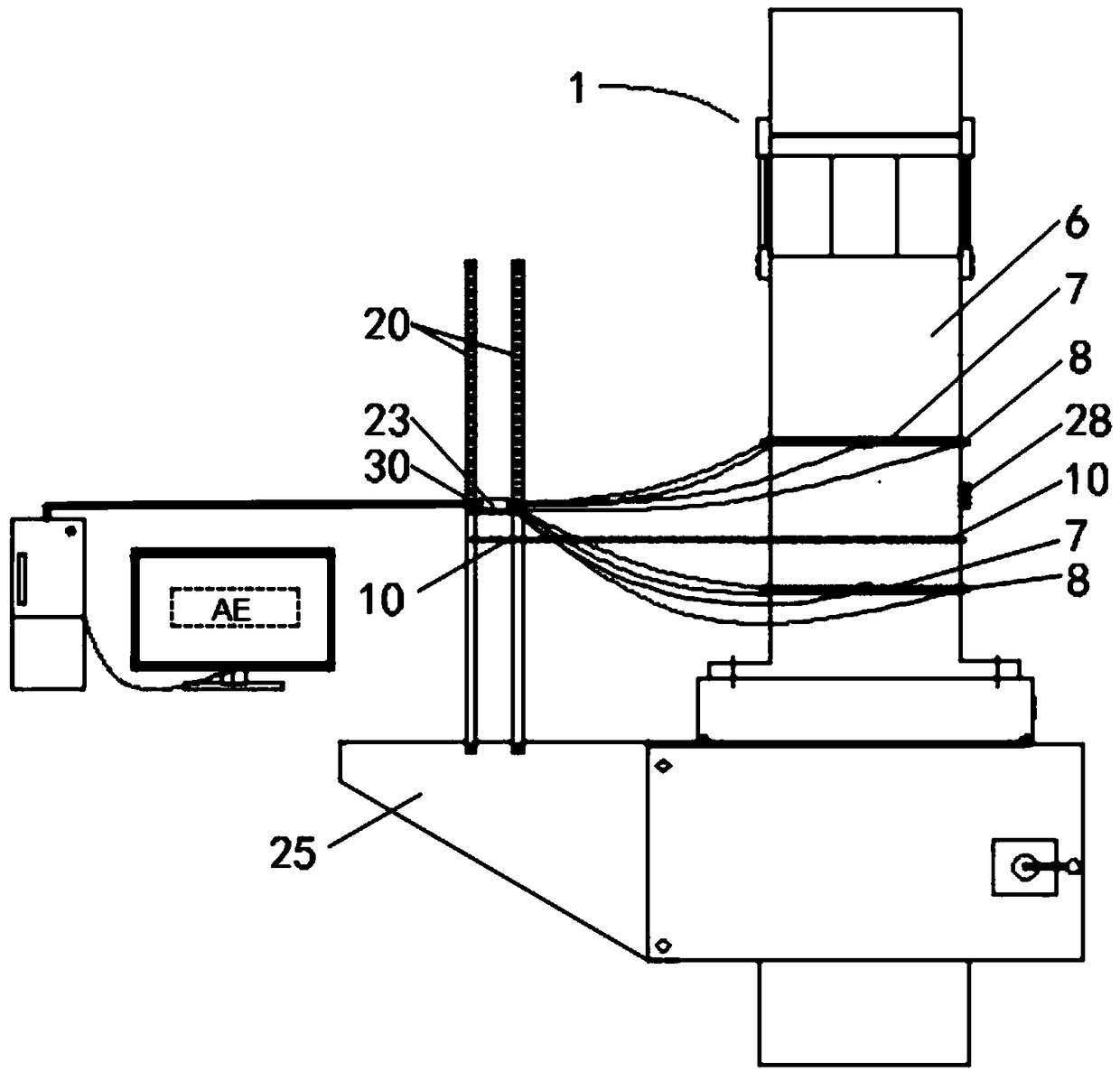

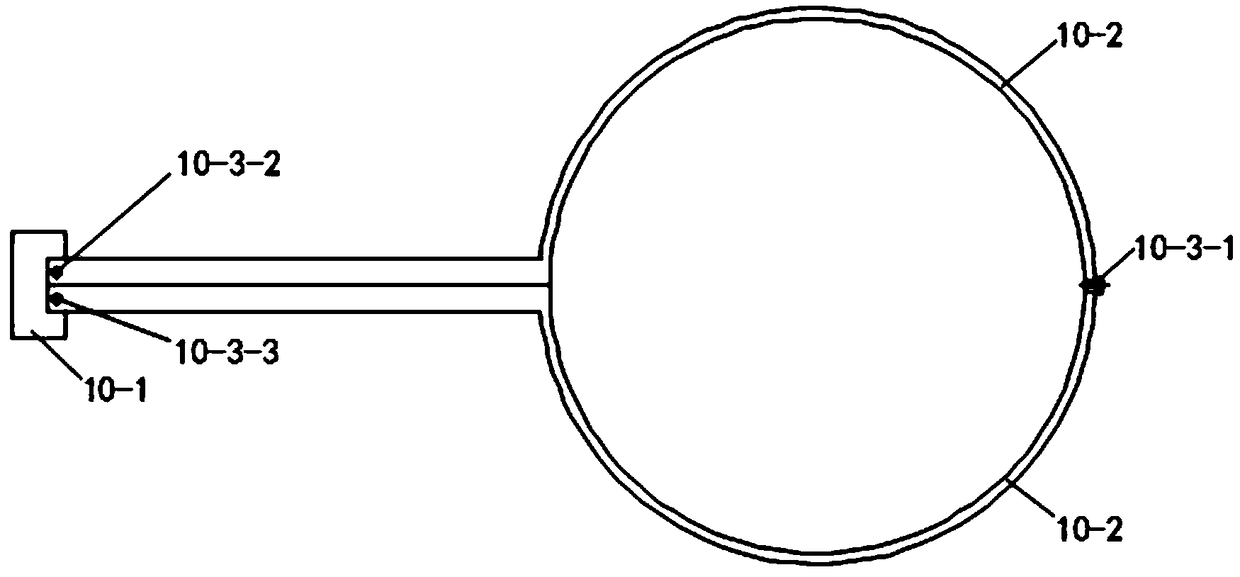

[0056] Such as Figure 1-Figure 18 As shown, the test system for the temporal-spatial evolution of failure in the complex deep rock environment of this embodiment includes an acoustic emission sensor assembly and an acoustic emission amplifier assembly installed on the rock mechanics testing machine 1. The rock mechanics testing machine 1 includes a three-axis Cavity base 13, triaxial chamber 6 installed on the triaxial chamber base 13, triaxial chamber lifting cylinder 2 fixedly installed on the top frame of rock mechanics testing machine 1, the output end of triaxial chamber lifting cylinder 2 is equipped with a lifting rod 3 and the lifting lower end 4 of the lifting rod 3 is fixed on the top of the triaxial cavity 6, and the inner cavity of the triaxial cavity 6 is coaxially installed with a column 5, a test piece indenter 9, and an indenter base 11, and the column 5 is fixed by bolts On the top frame of the rock mechanics testing machine 1, the indenter base 11 is fixed o...

Embodiment 2

[0080] The test system for the spatiotemporal evolution of damage in deep rock complex environments in this embodiment includes an acoustic emission sensor assembly and an acoustic emission amplifier assembly installed on a rock mechanics testing machine 1, and the rock mechanics testing machine 1 includes a three-axis cavity base 13 , the triaxial chamber 6 installed on the triaxial chamber base 13, the triaxial chamber lifting cylinder 2 fixedly installed on the top frame of the rock mechanics testing machine 1, the output end of the triaxial chamber lifting cylinder 2 is installed with a lifting rod 3 and lifted The lifting lower end 4 of the rod 3 is fixed on the top of the triaxial cavity 6, and the inner cavity of the triaxial cavity 6 is coaxially installed with a column 5, a test piece indenter 9, and an indenter base 11 from top to bottom. On the top frame of the testing machine 1, the indenter base 11 is fixed on the three-axis cavity base 13, the space between the te...

Embodiment 3

[0086] The test system for the spatiotemporal evolution of damage in deep rock complex environments in this embodiment includes an acoustic emission sensor assembly and an acoustic emission amplifier assembly installed on a rock mechanics testing machine 1, and the rock mechanics testing machine 1 includes a three-axis cavity base 13 , the triaxial chamber 6 installed on the triaxial chamber base 13, the triaxial chamber lifting cylinder 2 fixedly installed on the top frame of the rock mechanics testing machine 1, the output end of the triaxial chamber lifting cylinder 2 is installed with a lifting rod 3 and lifted The lifting lower end 4 of the rod 3 is fixed on the top of the triaxial cavity 6, and the inner cavity of the triaxial cavity 6 is coaxially installed with a column 5, a test piece indenter 9, and an indenter base 11 from top to bottom. On the top frame of the testing machine 1, the indenter base 11 is fixed on the three-axis cavity base 13, the space between the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com