Ultralow temperature environment composite sealing member seal reliability verifying method

A composite sealing and reliability technology, which is used in liquid/vacuum measurement for liquid tightness, machine sealing ring testing, and mechanical component testing. , to achieve the effect of simple and easy test, strong representativeness and strong test versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

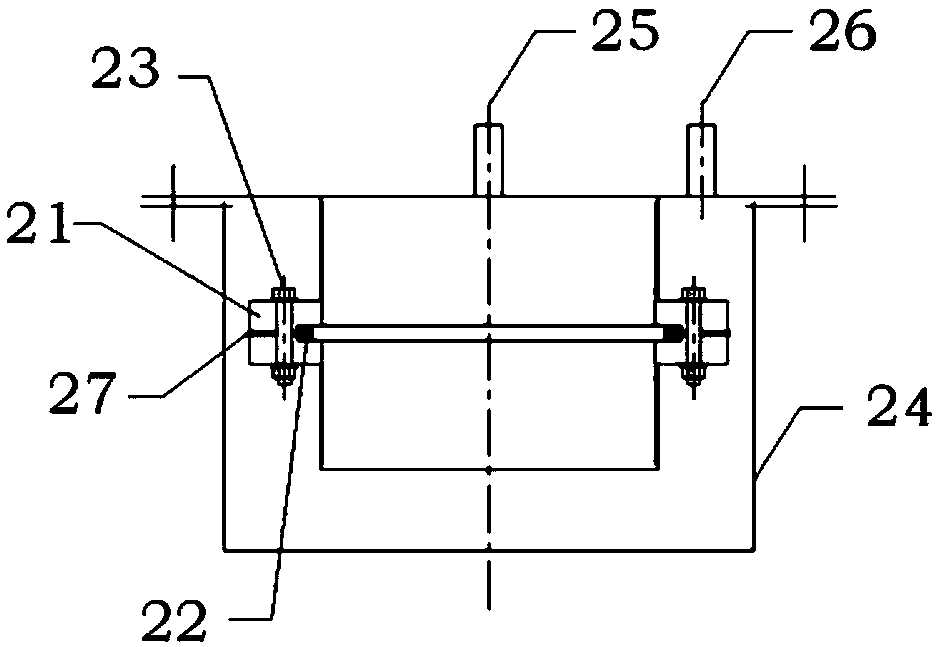

[0071] (1) Prepare composite seals with fluorine rubber with an I-shaped radial cross section of the skeleton and a circular ring in the axial cross section of the stainless steel skeleton, and prepare 3 sets of stainless steel integral flange structure test fixtures. Each tooling prepares 12 pieces of M8×40 stainless steel bolts, 12 pieces of M8 stainless steel nuts, 12 pieces of stainless steel spring washers with a diameter of 8 and 24 pieces of stainless steel flat washers with a diameter of 8 and a thickness of 1.5. Prepare enough liquid hydrogen medium, helium mass spectrometer leak detector, torque wrench, plug gauge and red copper gasket with a thickness of 0.05mm ~ 0.3mm. Comments on the sealing test system of this embodiment figure 1 (1 high-pressure gas cylinder; 2 valve; 3 pressure gauge; 4 pressure reducer; 5 test tooling; 6 insulation barrel; 7 temperature range; 8 helium mass spectrometer; 9 vacuum pump), the tooling structure is shown in 2, and 21 flanges in the ...

Embodiment 2

[0076] (1) Prepare a composite seal with a trapezoid in the radial cross section of the skeleton and a circular ring in the axial cross section of the silicone rubber half-enclosing the polyether ether ketone skeleton, and prepare 3 sets of aluminum alloy loose flange structure test fixtures. Each set of tooling prepares 16 pieces of M6×44 aluminum alloy bolts, 16 pieces of M6 aluminum alloy nuts, 16 pieces of stainless steel spring washers with diameter 6 and 32 pieces of stainless steel flat washers with diameter 6 and thickness 1. Prepare enough liquid nitrogen medium, helium mass spectrometer leak detector, pressure gauge, torque wrench, plug gauge and brass gasket with thickness 0.1mm~0.5mm.

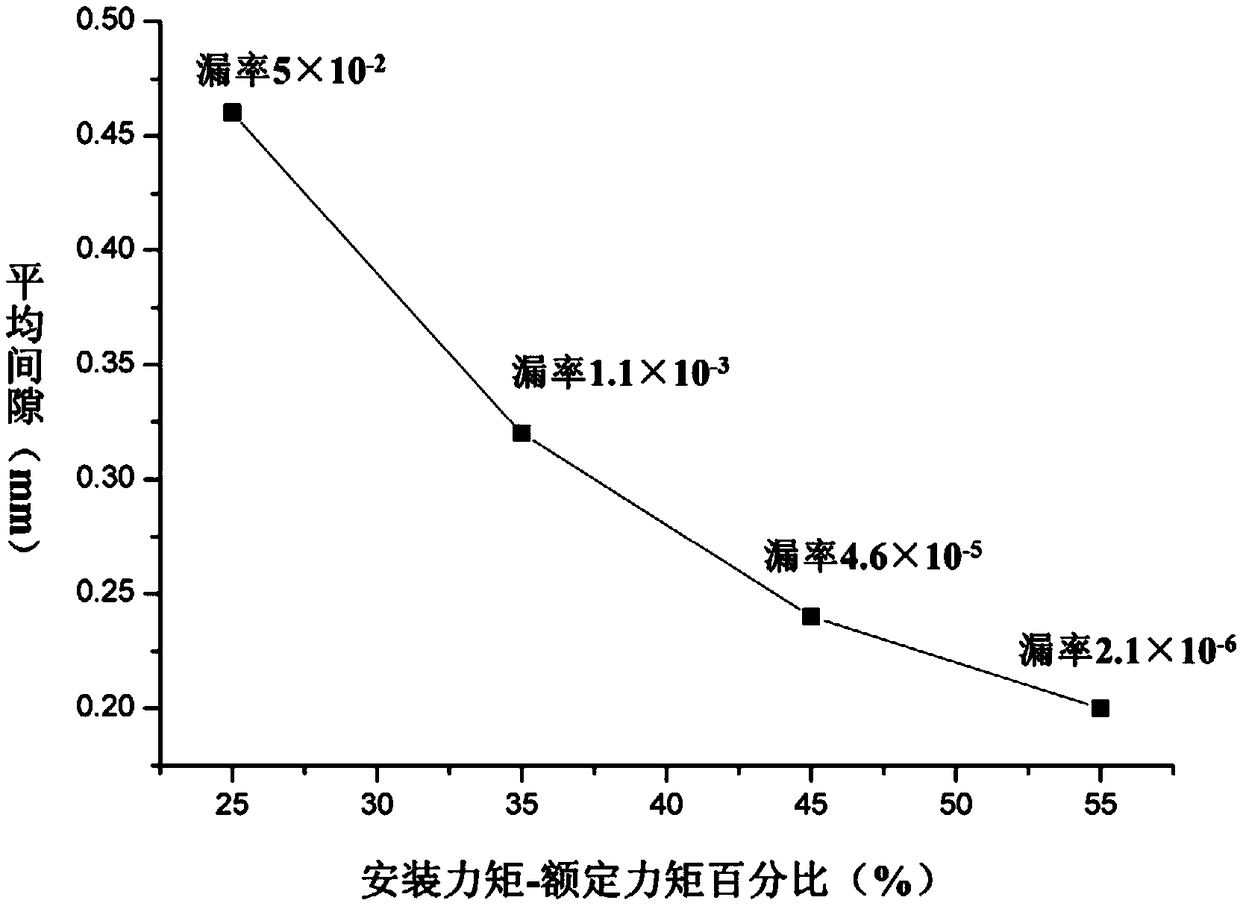

[0077] (2) Torque variable test: Check whether the test tool groove is defective, measure and record the groove inner diameter, groove outer diameter and groove depth of the sealed groove. Check the surface condition of the seal used in the test and measure the inner diameter, outer di...

Embodiment 3

[0083] (1) Prepare composite seals with butyl rubber with a rectangular radial cross-section of the skeleton and a circular ring in the axial cross-section of the superalloy skeleton, and prepare 6 sets of aluminum alloy integral flange structure test fixtures. Each set of tooling prepares 8 pieces of M10×48 high-temperature alloy bolts, 8 pieces of M10 high-temperature alloy nuts, 8 pieces of high-temperature alloy spring washers with a diameter of 10, and 16 pieces of high-temperature alloy flat washers with a diameter of 10 and a thickness of 1.5. Prepare enough liquid hydrogen and liquid nitrogen media, helium mass spectrometer leak detector, torque wrench, plug gauge and aluminum gasket with a thickness of 0.05mm to 0.4mm.

[0084] (2) Torque variable test: Check whether the test tool groove is defective, measure and record the groove inner diameter and groove depth of the sealed groove. Check the surface condition of the seal used in the test and measure the inner diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com