Construction method for limiting thermal expansion and cold shrinkage of steel belt reinforced polyethylene helical bellows

A technology of polyethylene spiral and construction method, which is applied in the direction of pipeline connection arrangement, pipeline laying and maintenance, pipe/pipe joint/pipe fitting, etc., which can solve the problem of large thermal expansion and cold contraction, increased construction cost, cracking and water leakage at the pipe mouth, etc. problems, to achieve the effect of reducing thermal expansion and contraction, reducing the frequency of later maintenance, and reducing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The construction method for restricting the thermal expansion and contraction of the steel belt reinforced polyethylene spiral corrugated pipe provided by the present invention includes the following steps:

[0039] Step one, construction preparation

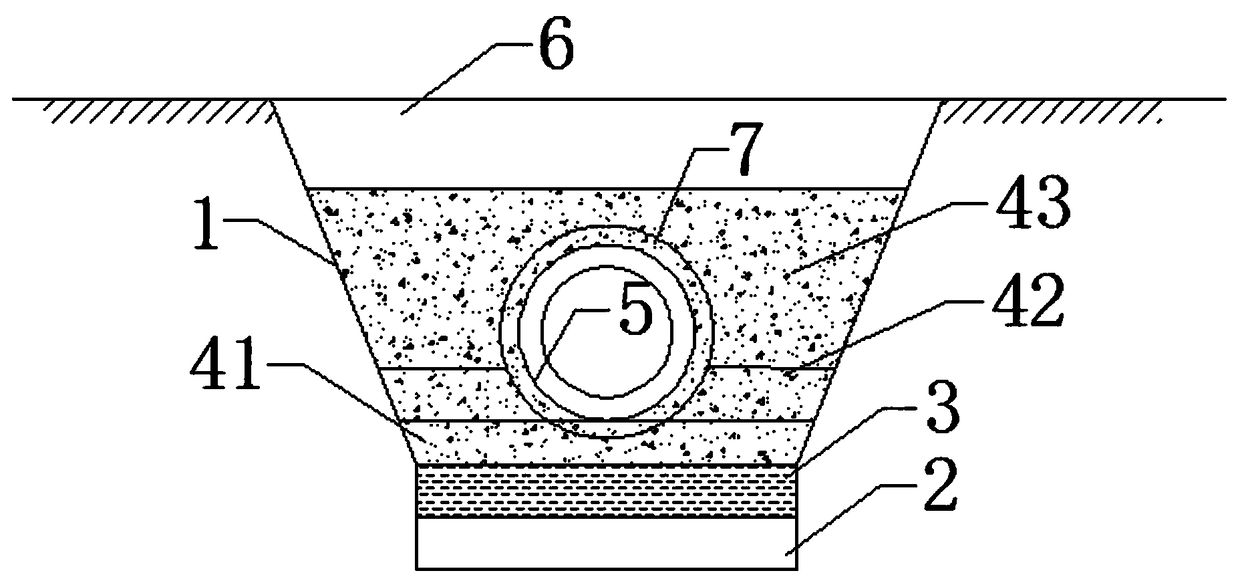

[0040] Clean the road to be excavated, determine the specifications and position of the corrugated pipe 5 according to the requirements of the drawings, and calculate the width and the width of the foundation pit 1 needed to be excavated by using the width of the foundation pit = pipe diameter + 2 × the width of the working surface on one side of the pipeline Depth, level the pavement to be excavated, measure according to the requirements and release the center line and sideline of foundation pit 1, and draw the actual shape of foundation pit 1 with gray lines.

[0041] In this step, each line is clearly marked to facilitate the construction of the foundation pit 1.

[0042] Step 2. Excavation of foundation pit 1

[0043] Excavati...

Embodiment 2

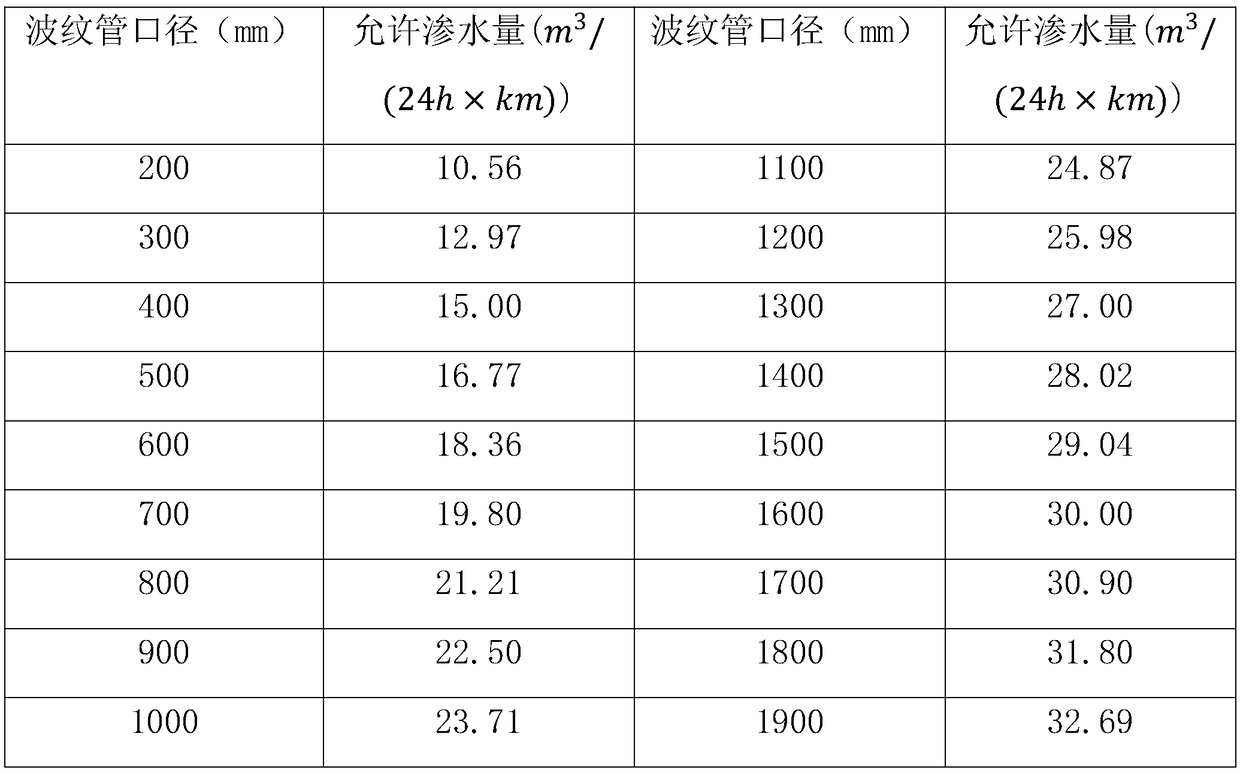

[0066] Compared with the embodiment 1, the method selected in step 4 is different in this embodiment: for the corrugated tube 5 of medium caliber such as DN500-DN1400, the composite electric heating tape heating shrinkage tube connection method is adopted. First, the corrugated tube 5 is cleaned. If there is dirt, the surface of the bellows 5 in the welding area should not be exposed to moisture or oil. If it does, it needs to be cleaned with a wet towel or flux solvent. The bellows 5 is welded according to the prescribed operation. After the welding is completed, the weld seam still needs to be visually inspected; the large-diameter bellows interface is reinforced by the bellows connection auxiliary device 7.

Embodiment 3

[0068] Compared with embodiment 1, the method selected in step 4 is different in this embodiment: for the outer wall of large-diameter corrugated pipes above DN1400, the combined process of connecting electric heating tape and connecting heat shrinkable pipe is adopted, and at the same time, polyethylene welding wire is used for the inner wall of the bellows 5 interface. For hot-melt extrusion welding, the welding seam still needs to be visually inspected after the welding is completed; for the large-diameter bellows interface, the bellows connection auxiliary device 7 is used for reinforcement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com