Earthen kiln folk house wall prestressed reinforcement structure

A technology for strengthening structures and prestressing, applied in building construction, building maintenance, construction, etc., can solve problems such as no guidance plan is given, and achieve the effect of enhanced integrity, high strength and integrity, and enhanced integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

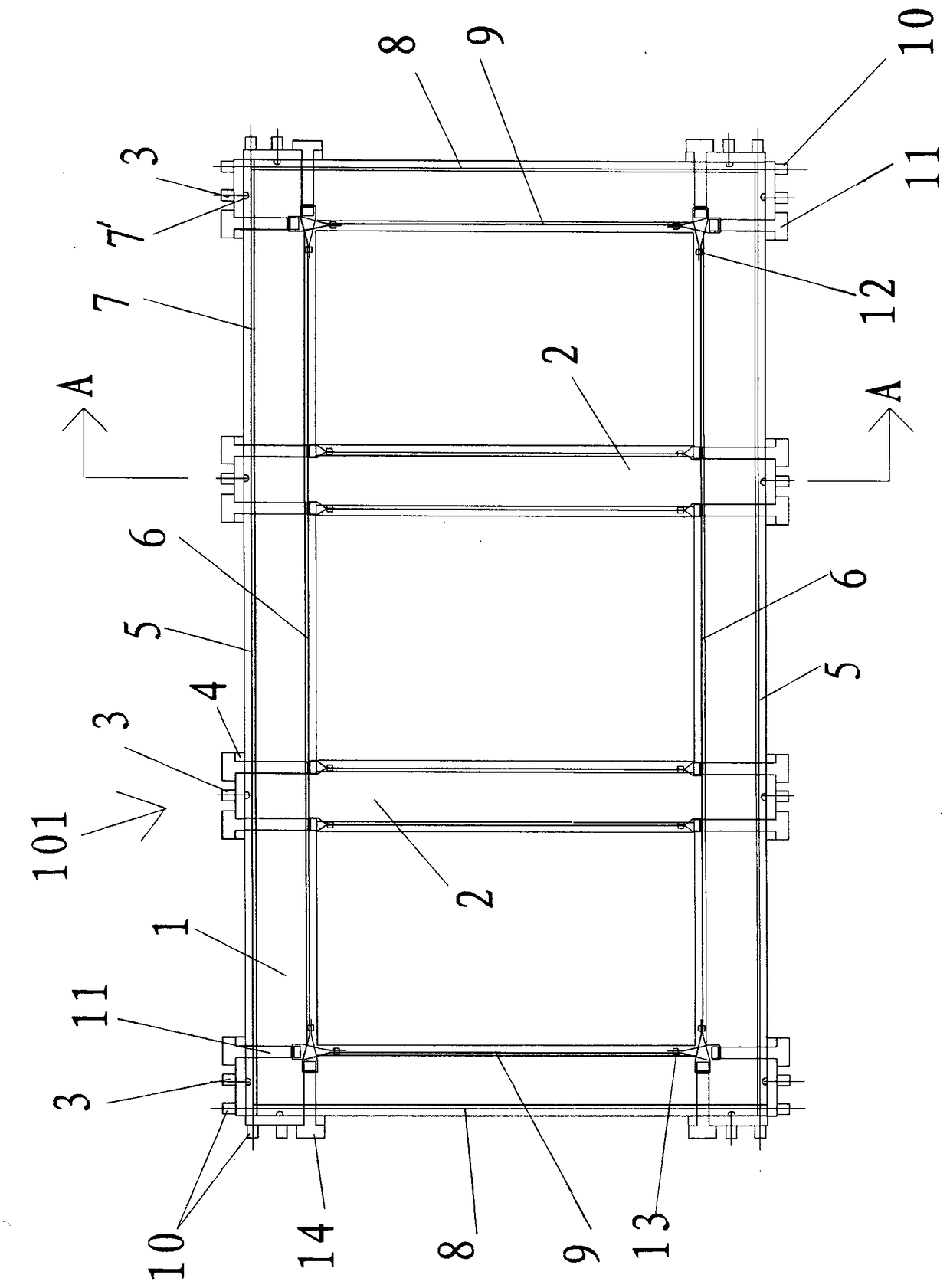

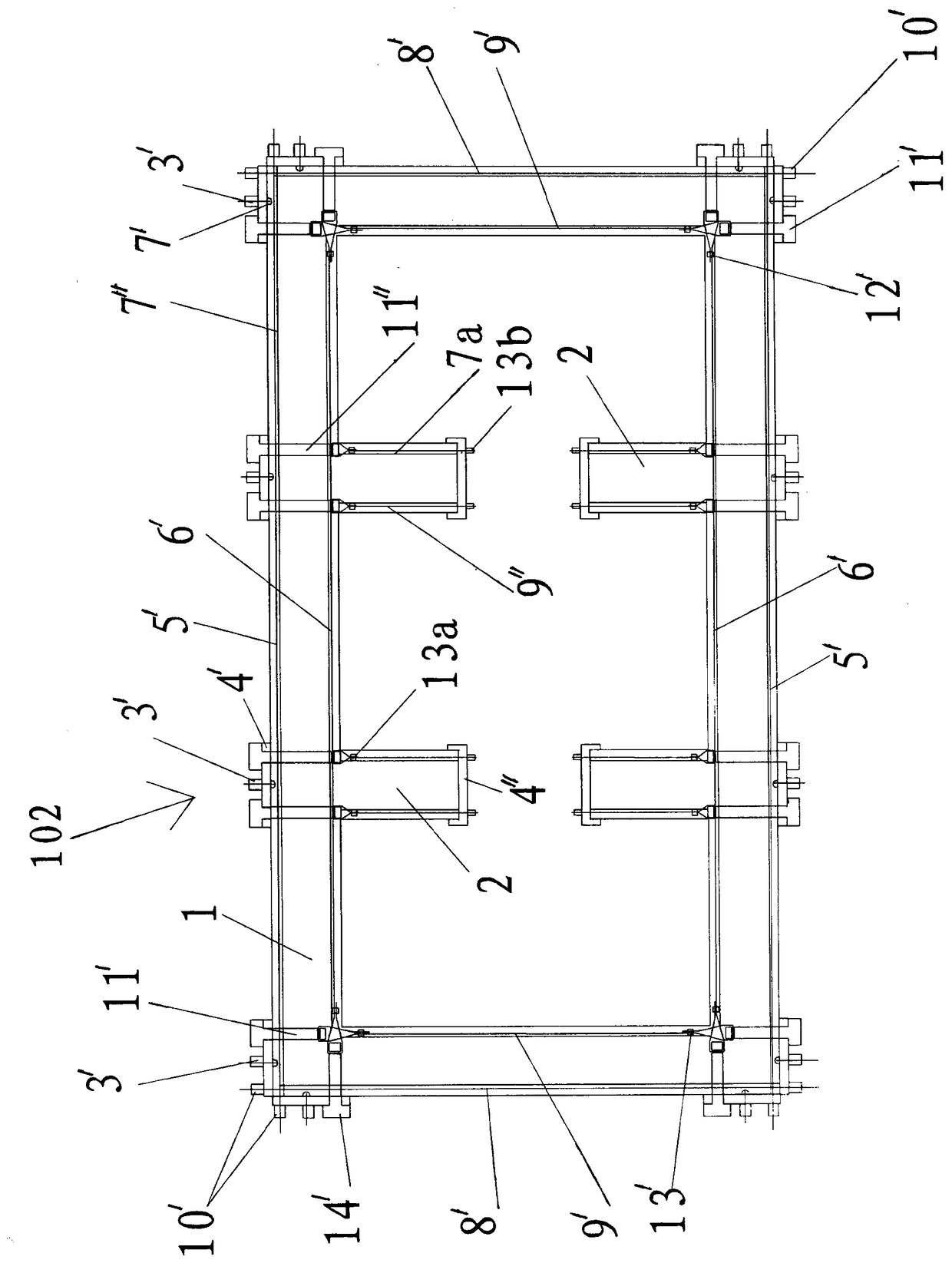

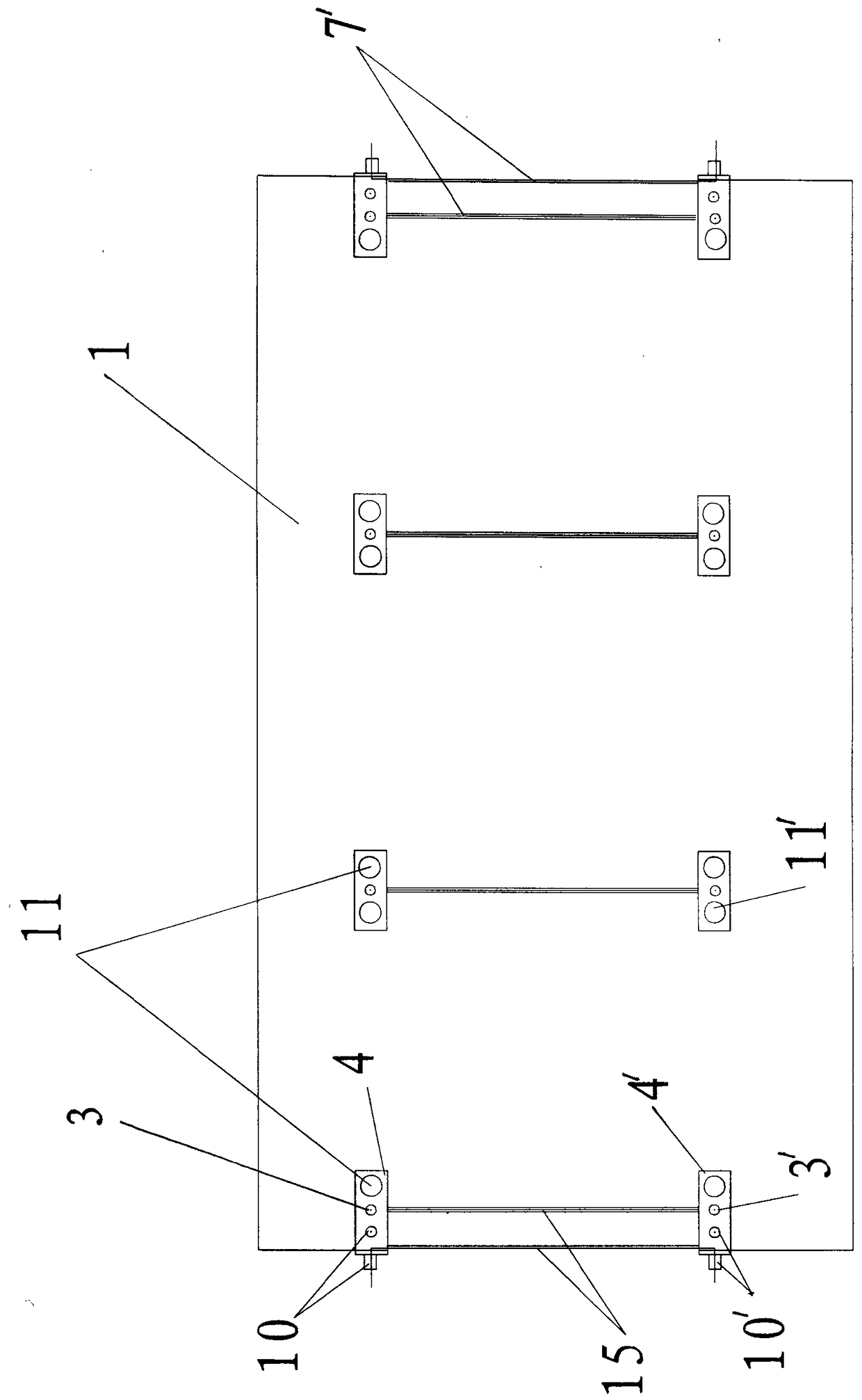

[0024] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 As shown, the earth kiln residential wall prestressed reinforcement structure of the present invention has an outer wall 1 and an inner wall 2 . The outer wall 1 is four walls, and the inner wall 2 is a plurality of walls, that is, a plurality of inner walls (can be two inner walls, that is, two walls). Its technical solution is that the prestressed reinforced structure of the earth kiln residential wall also has an upper reinforcement ring 101 installed on the upper part of the outer wall 1 and the inner wall 2, and a lower reinforcement ring installed on the lower part of the outer wall 1 and the inner wall 2. 102. A plurality of prestressed anchor cables 15 arranged vertically connecting the upper reinforcement ring and the lower reinforcement ring, and a plurality of first anchor heads 3 installed on the upper reinforcement ring to anchor the upper end of each prestressed anchor cable 15 , a plurality ...

Embodiment 2

[0029] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 Shown, earthen kiln dwelling house wall prestressed reinforcing construction technique of the present invention comprises the steps:

[0030] ① Wall measurement.

[0031] a. Measure the width, height and thickness of the kiln wall.

[0032] b. According to the measured results, determine the positions of the drill holes and grooves, and mark them respectively. The drilling position is symmetrical along the center line of the wall, the axis of the hole coincides with the groove, and the groove (open groove) on the same layer is in the same plane as the hole.

[0033] ② Prefabrication of components.

[0034]a, steel plate prefabrication, steel plate punching, that is (each) the through hole on both sides of the first backing plate 4 is the drilling (punching, hole) and the said drilling (hole) on the outer wall and the outer wall Corresponding to the first opening slot, the through holes on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com