Anastomotic nail and preparation method and application thereof

A staple and magnesium alloy technology, applied in the field of staple and its preparation, can solve the problems of non-degradability, toxicity, poor biocompatibility, etc., and achieve the effects of alleviating stress shielding effect, high yield strength, and good biological safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

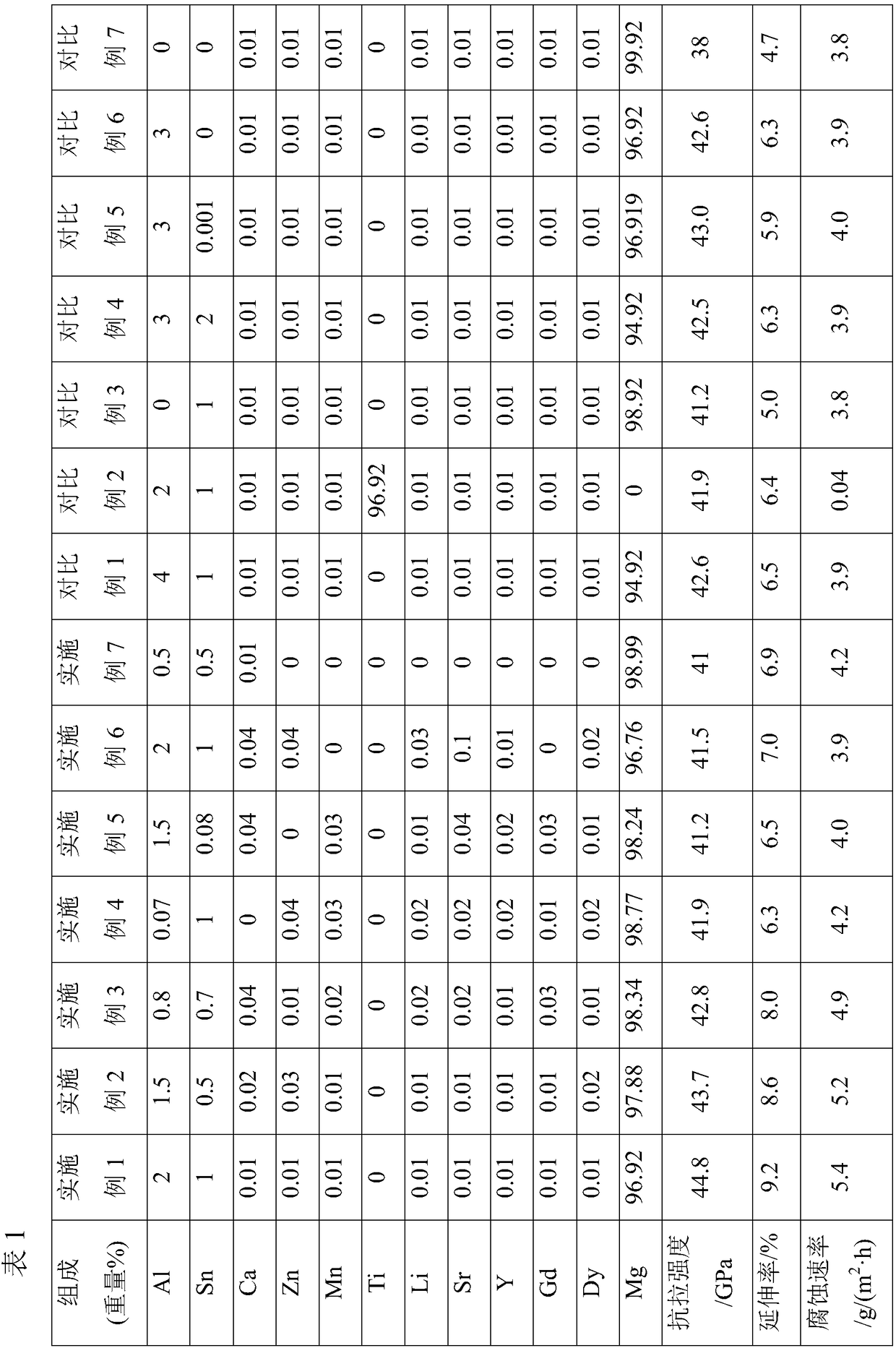

Embodiment 1-7 and comparative example 1-7

[0050] In weight percentage, each component in the composition of the magnesium alloy is mixed to prepare the magnesium alloy raw material. Put the prepared alloy raw material in a melting furnace for melting, feed 99.99% high-purity argon gas into the melting process, and smelt at a temperature of 720° C. for 30 minutes. The obtained melt is poured into a metal mold, and after cooling, a magnesium alloy ingot is obtained. Subsequently, the magnesium alloy ingot was subjected to homogenization treatment at 350° C. for 12 hours, and the homogenized alloy ingot was directly subjected to hot extrusion with an extrusion ratio of 17 and an extrusion temperature of 250° C. to obtain Primary billet. The primary billet is cut and turned, and then quenched after solution treatment at 300°C for 8 hours to form a secondary billet. Afterwards, the obtained secondary blank is subjected to multi-pass continuous drawing to form a magnesium alloy wire with a diameter of 0.23 mm. Wherein, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com