Preparation method of BN/epoxy resin heat conductive insulation composite material

An epoxy resin and thermal insulation technology, which is applied in the field of preparation of boron nitride/epoxy resin composite materials, can solve the problems such as the inability to form a good thermal conduction path, the inability to disperse, and the easy occurrence of pores, so as to achieve favorable heat transfer. , The effect of inhibiting the generation of pores, simple and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

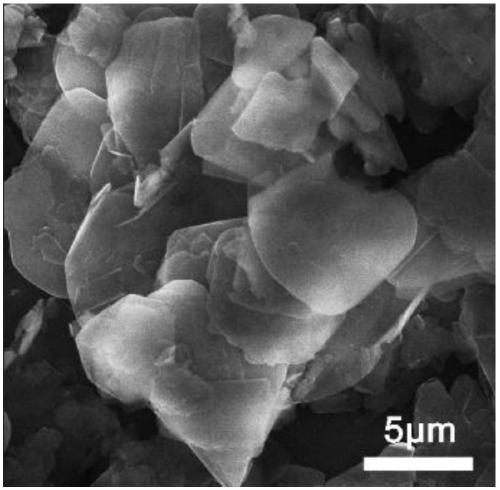

[0032] Embodiment 1: add the example of hexagonal boron nitride micropowder

[0033] (1) Weigh 0.75g of hexagonal boron nitride micropowder (h-BN) with a particle size of about 44 microns, place it in the ark, heat it to 1000°C in the air at a heating rate of 10°C / min, and keep it warm After 2h, cool down to room temperature naturally after heating, take out the sample and grind it carefully.

[0034] (2) Take the silane coupling agent (KH-550) with 5% mass of hexagonal boron nitride micropowder, drop it into the absolute ethanol aqueous solution, the mass ratio of the silane coupling agent, absolute ethanol and deionized water is 1:144 :16, magnetically stir the solution for 30min, after the silane coupling agent is fully hydrolyzed, add annealed hexagonal boron nitride micropowder, heat in a water bath to 60°C and stir for 2h, cool naturally after stirring, vacuum filter and wash 3 times with absolute ethanol , and dried in a vacuum oven at 110° C. for 12 hours to obtain mo...

Embodiment 2

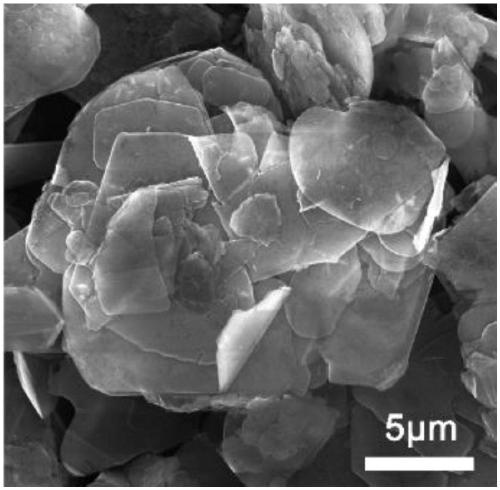

[0036] Embodiment 2: the example of adding hexagonal boron nitride nanosheets

[0037] (1) Weigh 0.75 g of hexagonal boron nitride nanosheets with a thickness of about 50 nm, place them in the ark, and heat them to 1000 °C in the air at a heating rate of 10 °C / min, and keep them warm for 2 hours. After cooling to room temperature, the samples were taken out and carefully ground.

[0038] (2) Get the silane coupling agent KH-550 of 5% of the quality of the hexagonal boron nitride nanosheets, drop it into the absolute ethanol aqueous solution, the mass ratio of the silane coupling agent to absolute ethanol and deionized water is 1:144: 16. Magnetically stir the solution for 30 minutes. After the silane coupling agent is fully hydrolyzed, add the annealed hexagonal boron nitride nanosheets, heat in a water bath to 60°C and stir for 2 hours. After stirring, cool naturally, and vacuum filter and wash with absolute ethanol for 3 times. , dried in a vacuum oven at 110° C. for 12 hou...

Embodiment 3

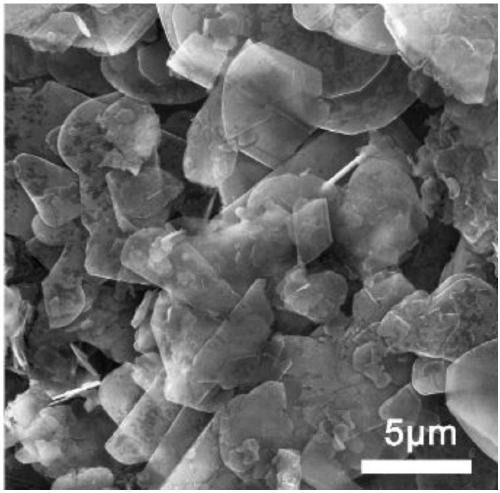

[0040] Embodiment 3: add the example of hexagonal boron nitride micropowder and cubic boron nitride micropowder

[0041] (1) Weigh 0.75g of hexagonal boron nitride micropowder (h-BN) with a particle size of about 9 microns, place it in the ark, heat it to 1000°C in the air at a heating rate of 10°C / min, and keep it warm After 2h, cool down to room temperature naturally after heating, take out the sample and grind it carefully. Weigh 2.25g of cubic boron nitride micropowder (c-BN) with a particle size of about 44 microns, place it in the ark, heat it to 750°C in the air at a heating rate of 10°C / min, and keep it warm for 1h. After completion, it was naturally cooled to room temperature, and the samples were taken out and carefully ground.

[0042] (2) Take the silane coupling agent KH-550 with 5% mass of hexagonal boron nitride micropowder, drop it into the absolute ethanol aqueous solution, the mass ratio of the silane coupling agent, absolute ethanol and deionized water is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com