PCB conveying line capable of being automatically adjusted in width

A PCB board, automatic adjustment technology, applied in the direction of conveyor, transportation and packaging, packaging, etc., can solve problems such as trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

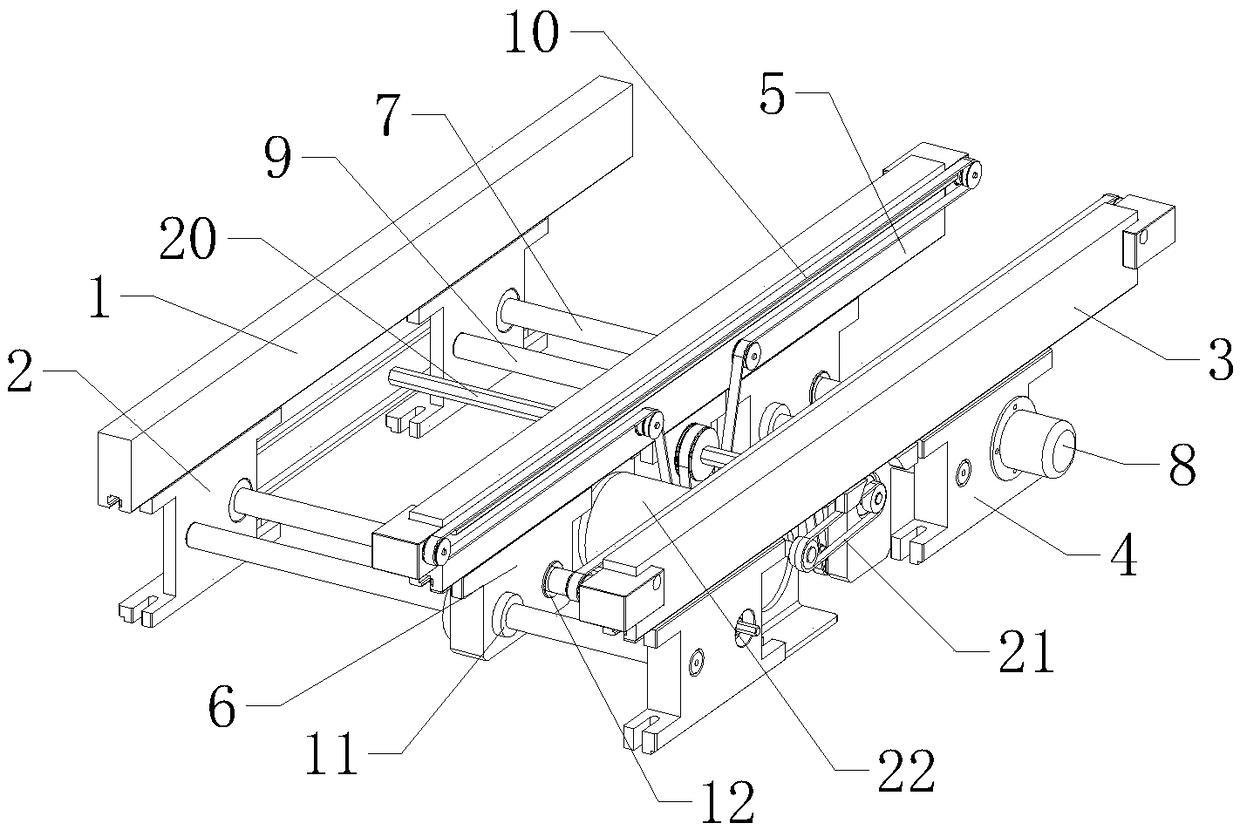

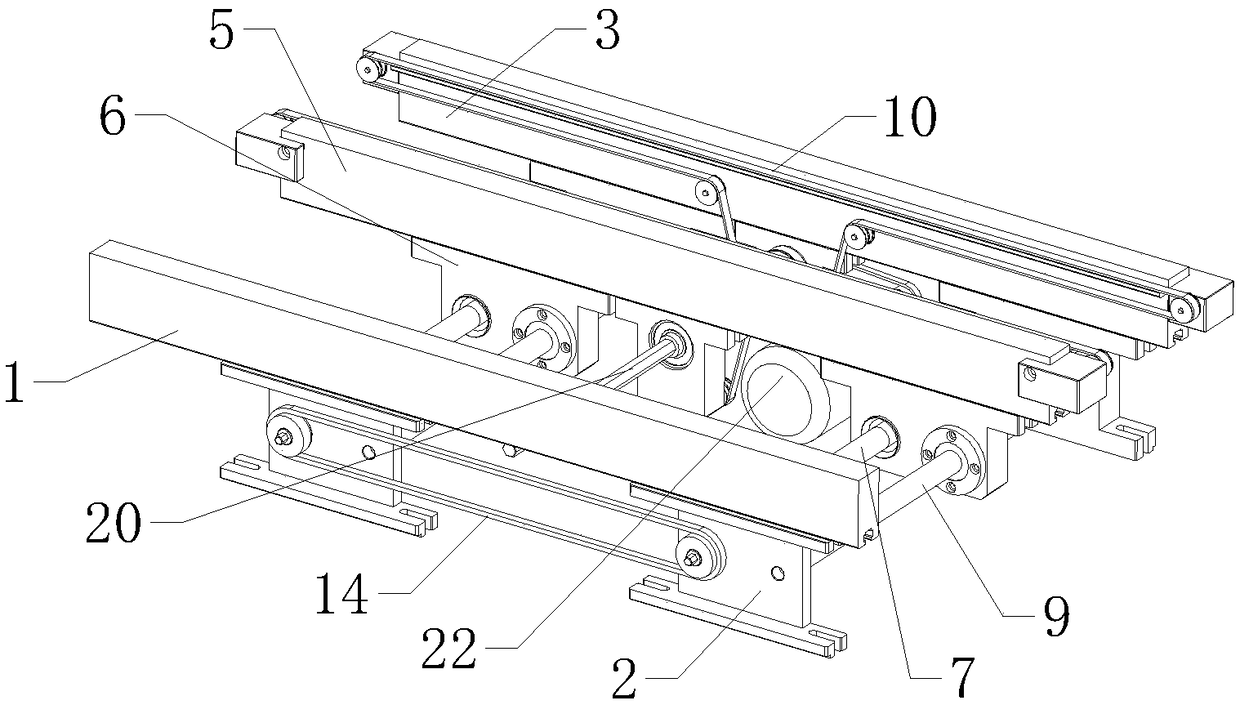

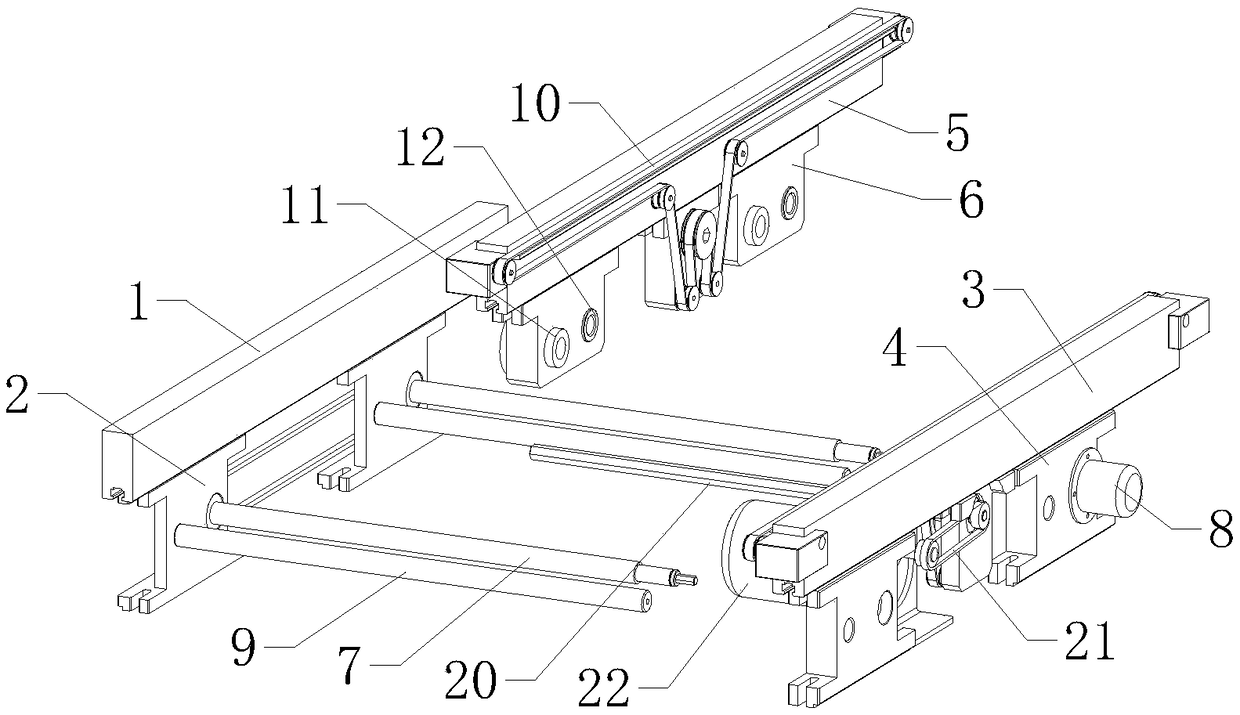

[0025] refer to Figure 1 to Figure 8 An automatic width-adjusting PCB conveying line is shown, including a left support assembly, a right support assembly, an adjustment assembly, and a drive assembly. The left support assembly, the right support assembly, and the adjustment assembly are all arranged horizontally and the tops of the three are flush. The left support assembly includes a first strip baffle 1 and two first support seats 2, the first strip baffle 1 is horizontally arranged on the top of the two first support seats 2, and the right support assembly includes a second strip baffle 3 and two second support bases 4, the second bar-shaped baffle plate 3 is horizontally arranged on the top of the two second support bases 4, and the adjustment assembly is movably arranged between the left support assembly and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com