Circular tube polishing and painting device

A technology for painting and round pipes, which is applied in the direction of spraying devices, liquid spraying devices, grinding drive devices, etc., can solve the problems that it is difficult to ensure the polishing and painting of round pipes evenly, increase the labor intensity of workers, and inconvenient operation, etc., to achieve Improve the efficiency of polishing and painting, reduce the labor burden of workers, and facilitate the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment proposes a circular tube polishing and painting device that can improve the painting efficiency and reduce the labor burden of workers.

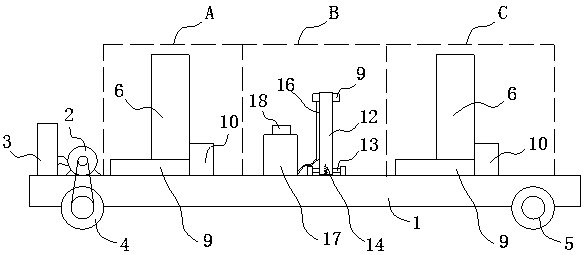

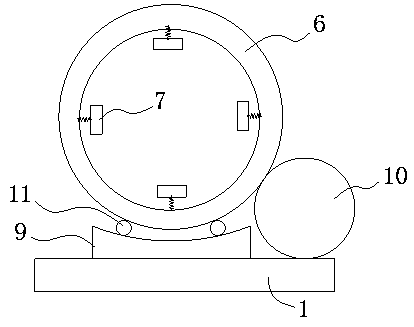

[0022] Such as Figure 1~4 As shown, the circular tube polishing and painting device of the present embodiment comprises a movable walking frame. 2 is composed of a storage battery 3 for power supply, and a driving wheel 4 and a driven wheel 5 are arranged under the frame body 1, and the driving wheel 4 is connected with the driving motor 2 through a belt. Utilize the drive motor 2 to drive the drive wheel 4 to rotate, thereby realizing the purpose of driving the walking frame to walk. The walking frame is also provided with a seat (not shown in the figure) for the workers to take.

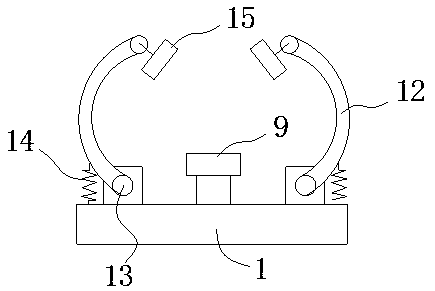

[0023] The frame body 1 is provided with a polishing mechanism A, a painting mechanism B and a painting mechanism C sequentially along the walking direction of the walking frame, wherein the structure of the polishing mechanism A is simi...

Embodiment 2

[0028] Such as Figure 5 , 6 As shown, different from Embodiment 1, in this embodiment, a drying mechanism D is also installed on the walking frame. An arc-shaped heating plate 20 is formed; the painting mechanism C is located between the drying mechanism D and the painting mechanism B. The heating plate 20 is powered by a storage battery. Before painting, the round pipe is also passed through the heating frame 19, so that after the paint brushing mechanism C paints the surface of the round pipe, the drying mechanism D heats the painting position of the round pipe immediately, so that the paint just brushed Quickly solidifies and loses fluidity, thereby avoiding uneven paint thickness on the surface of the round tube caused by paint flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com