Three-station medical bed pipe fitting automatic welding robot

An automatic welding and medical bed technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenient installation and movement, large volume, etc., and achieve convenient disassembly and storage, small size and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

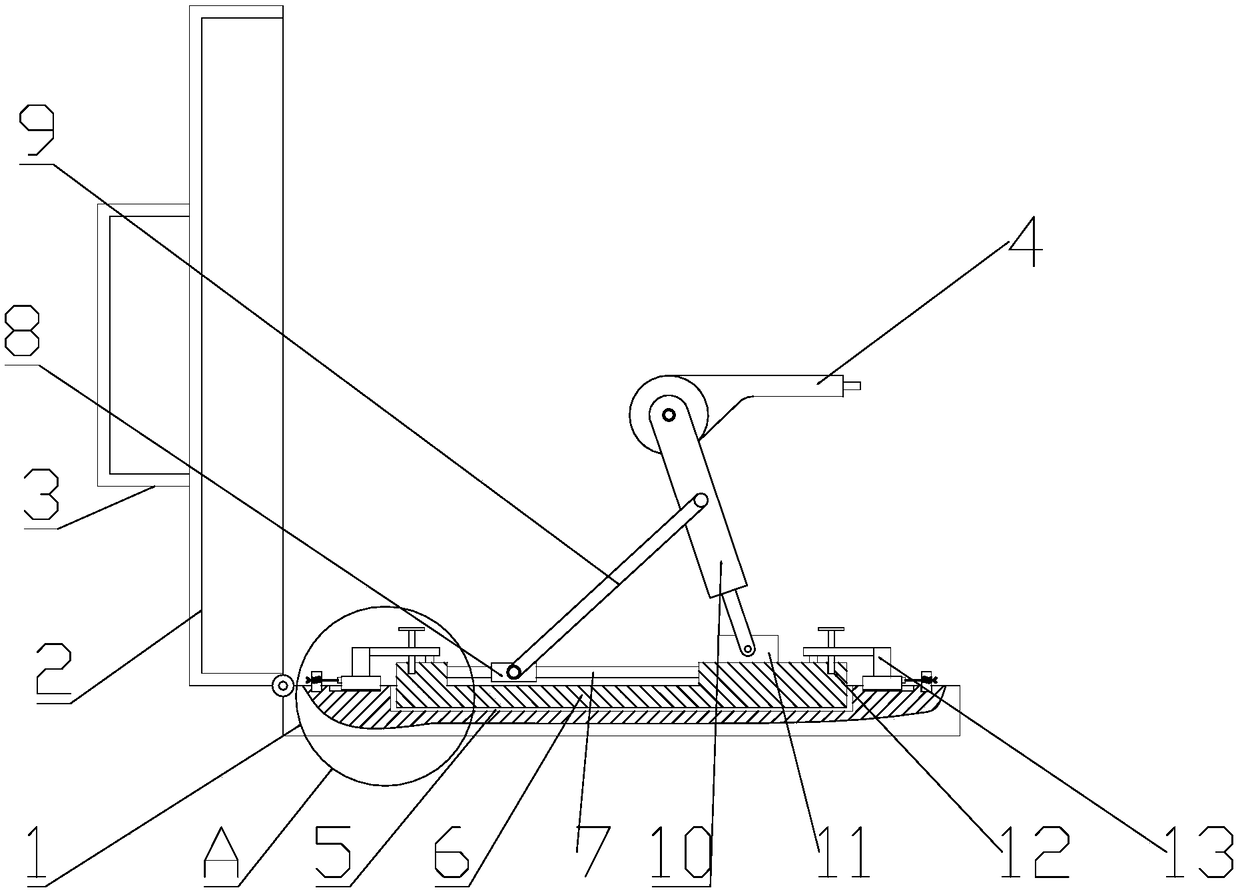

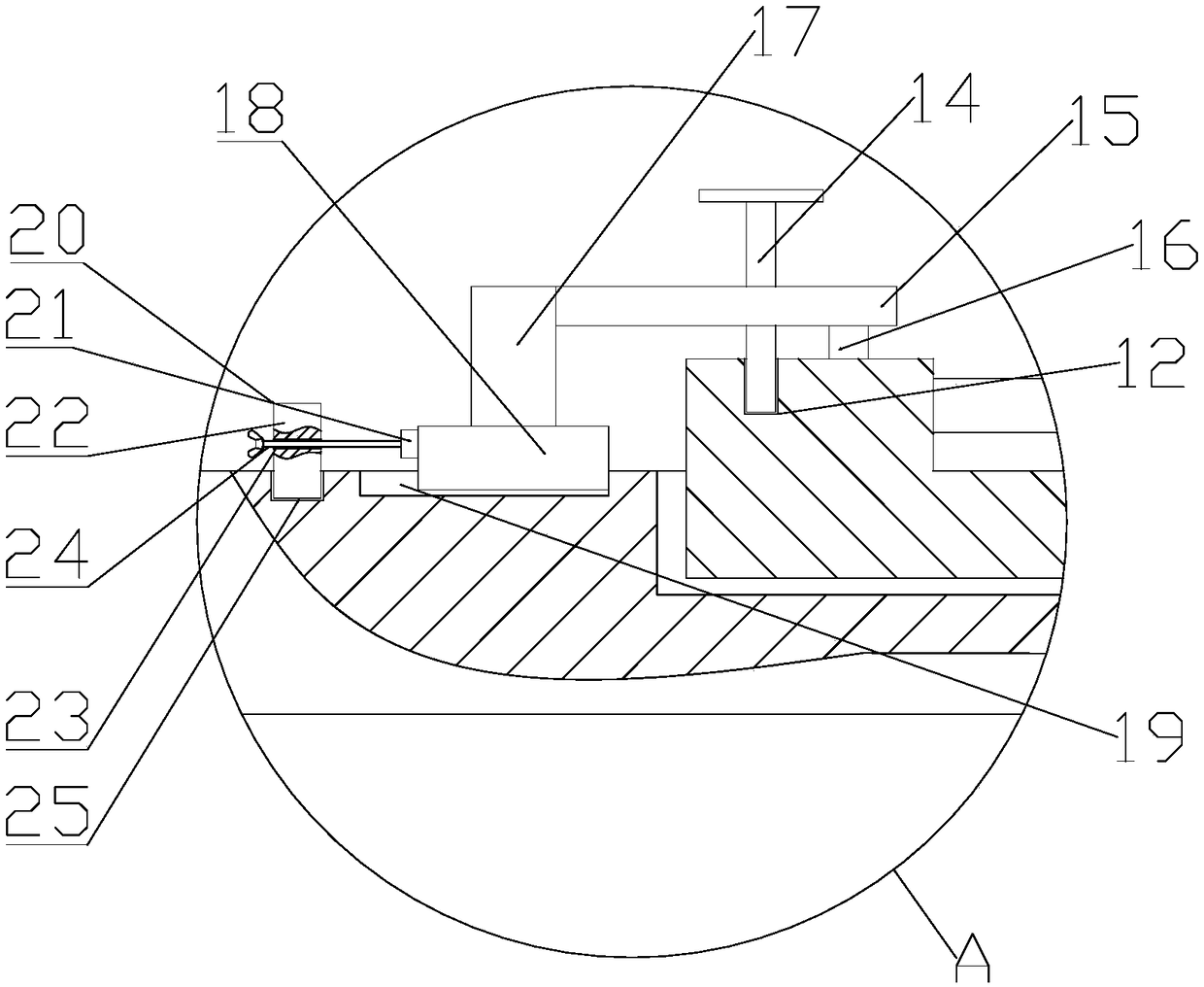

[0018] see figure 1 and figure 2 , a three-station medical bed pipe fittings automatic welding robot, including a base 1, a case cover 2, a handle 3 and a welding torch 4, the case cover 2 is rotatably mounted on the base 1, and the outer top bolts of the case cover 2 The handle 3 is fixed, the base 1 is provided with the welding torch 4; the base 1 is processed with a mounting groove 5, and a mounting platform 6 is placed in the mounting groove 5, and the mounting platform 6 is provided with There is a slide bar 7, a slide block 8 is installed to slide left and right on the slide bar 7, and the end of the connecting rod 9 is installed on the slide block 8, and the top end of the connecting rod 9 is rotatably installed on the column 10, and the column The bottom of 10 is rotatably installed on the boss 11, and the top of the column 10 is rotatably installed with the welding torch 4, so that the storage of the welding torch 4 can be realized by the rotation of the connecting ...

Embodiment 2

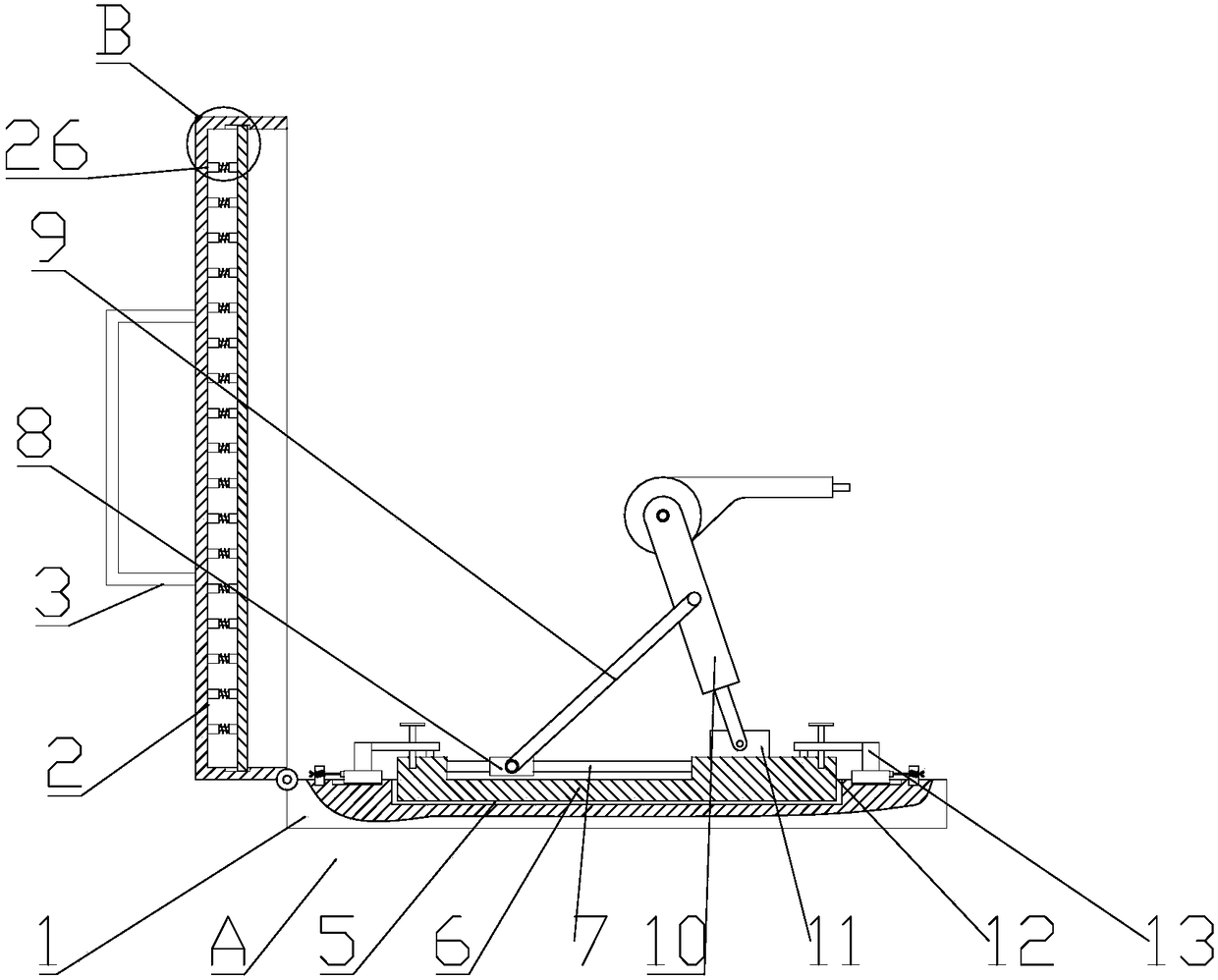

[0020] see image 3 and Figure 4 Compared with Embodiment 1, the difference between Embodiment 2 and Embodiment 1 is that the inner wall of the box cover 2 is provided with a shock absorbing mechanism 26 for buffering and shock absorbing during transportation, and the shock absorbing mechanism 26 includes a shock absorbing plate 27 , chute 28, spring seat 29, rod 30, spring 31 and sleeve 32, the damping plate 27 is slidably installed in the chute 28, and the chute 28 is opened on the left and right inner walls of the box cover 2 , the spring seat 29 is welded and fixed on the chute 28, the end of the rod 30 is welded and fixed on the spring seat 29, and the top end of the rod 30 is slidably installed in the sleeve 32, and the sleeve The cylinder 32 is welded and fixed on the top inner wall of the case cover 2 , and the spring 31 is sheathed on the outer side of the rod 30 .

[0021] The working principle of the present invention is: the storage of the welding torch 4 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com