Kitchen waste treatment system

A treatment system and technology for kitchen waste, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as no oil recovery, shutdown of treatment plants, poor resource utilization, etc., and achieve nutritional structure Reasonable, no secondary pollution, high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

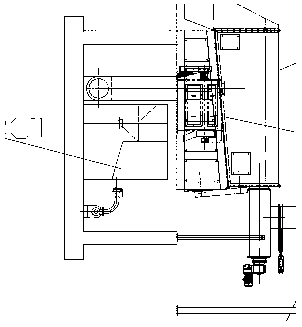

Image

Examples

Embodiment Construction

[0029] Such as Figure 1 to Figure 5 As shown in the figure, a food waste treatment system, which will carry out wet heat hydrolysis of the food waste after removing impurities in a special humid-heat heating kettle, control the wet-heat reaction conditions, effectively kill pathogenic bacteria, remove peculiar smell, and make the macromolecules in the garbage Organic matter is hydrolyzed into small molecular organic matter that is easily digested and absorbed by plants and animals. After hydrolysis, the material is dried and sieved to be used as raw material for making insect feed and fertilizer. This treatment system changes the physical and chemical form of oil in kitchen waste and the way it combines with other components, optimizes the interface characteristics of oil, promotes the efficient leaching, liquefaction, and floating of oil in the solid phase of kitchen waste, and improves the separation characteristics of kitchen waste oil , Through the special centrifugal and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com