A kind of preparation technology of rare earth concentrate

A technology of rare earth concentrate and preparation process, which is applied in solid separation, chemical instruments and methods, grain processing, etc. It can solve the problems of endangering the life and health of surrounding residents, affecting the economic benefits of enterprises, and polluting the surrounding environment, so as to improve the effect of acid dissolution , easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

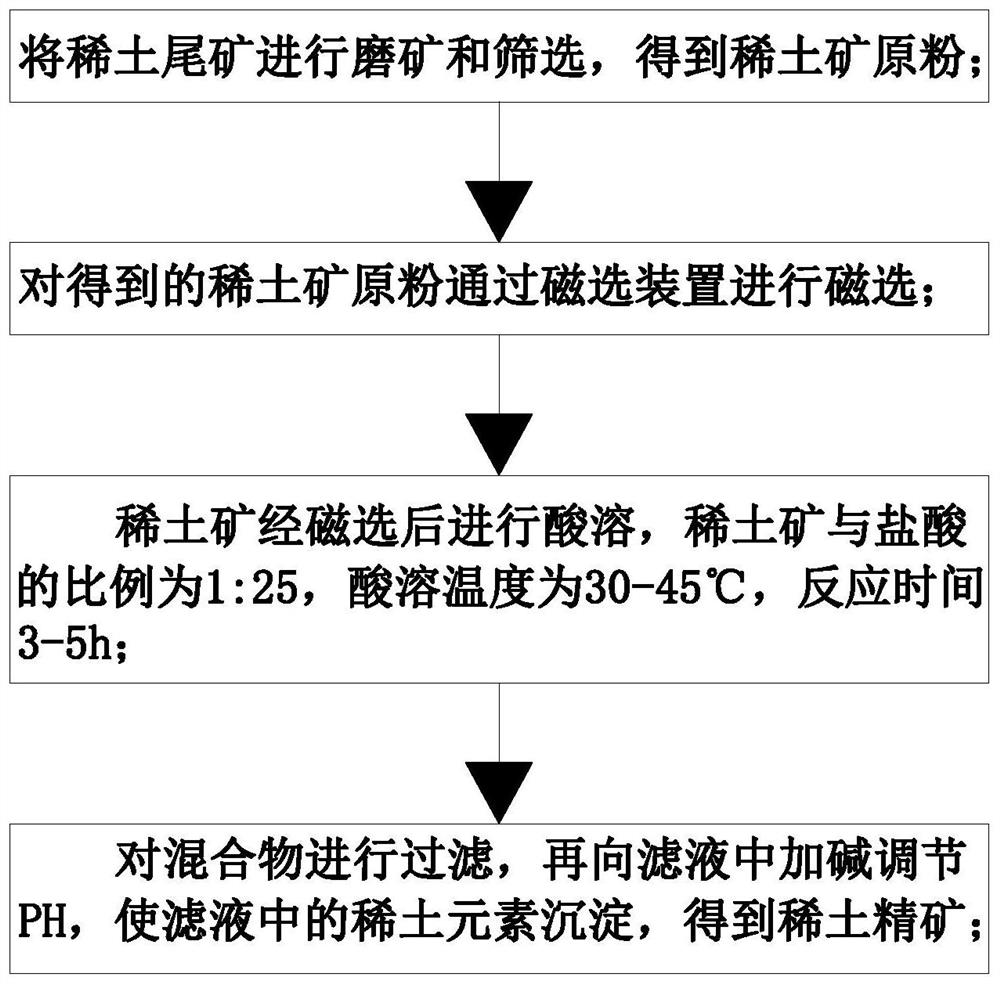

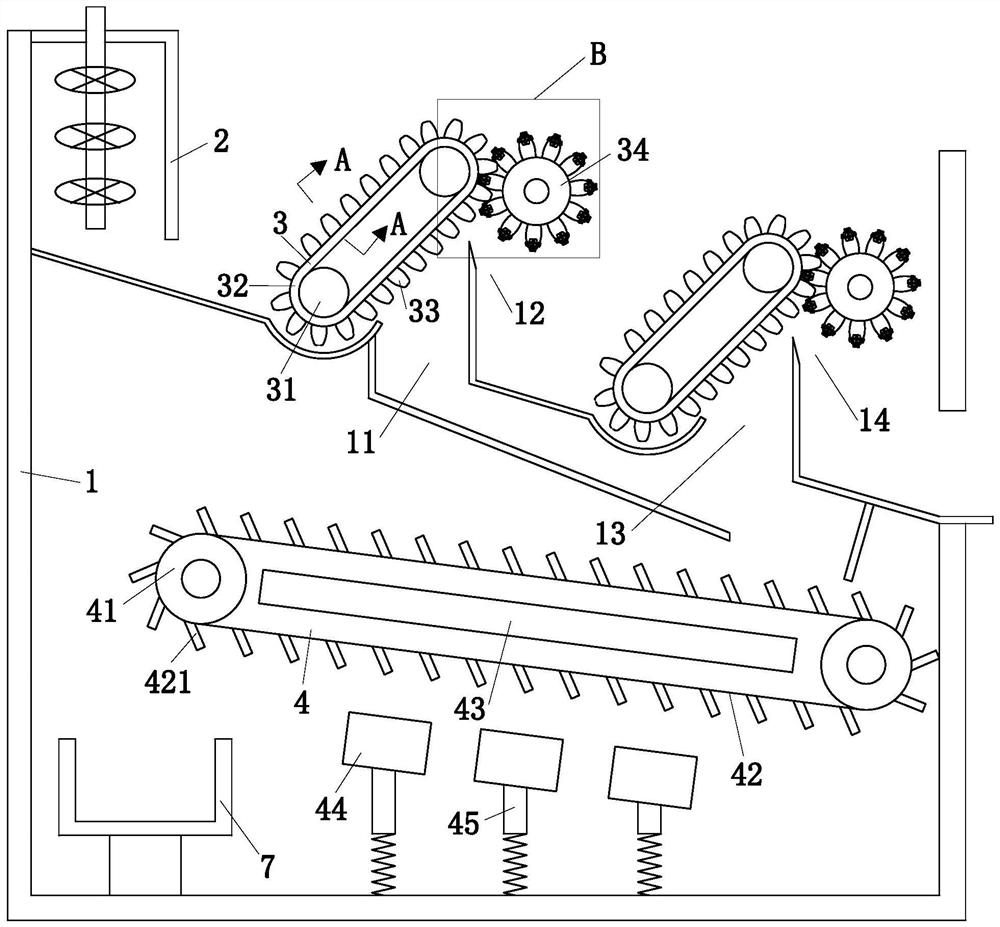

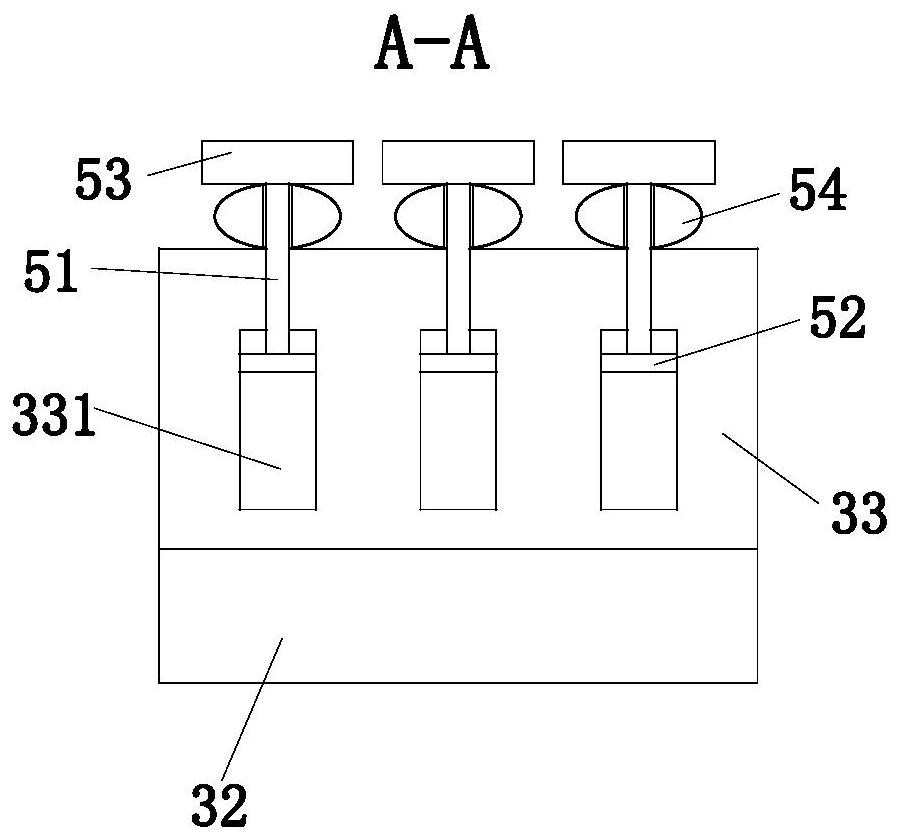

[0028] use Figure 1-Figure 5 The preparation process of a rare earth concentrate according to an embodiment of the present invention is described as follows.

[0029] Such as figure 1 , figure 2 and Figure 4 Shown, the preparation technology of a kind of rare earth concentrate of the present invention, this technology comprises the steps:

[0030] Step 1: Grinding and screening the rare earth tailings to obtain raw rare earth ore powder;

[0031] Step 2: Carry out magnetic separation to the raw rare earth ore powder obtained in step 1 through a magnetic separation device;

[0032] Step 3: The rare earth ore raw powder is subjected to acid dissolution after magnetic separation in step 2, the ratio of rare earth ore raw powder to hydrochloric acid is 1:25, the acid dissolution temperature is 30-45°C, and the reaction time is 3-5h;

[0033] Step 4: filter the mixture in step 3, and then add alkali to the filtrate to adjust the pH, so that the rare earth elements in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com