A scroll dynamic and static joint and a water-cooled oil-free scroll compressor

A scroll compressor and compressor technology, applied in the field of compressors, can solve the problems of increased heat production, increased friction loss, no lubricating oil cooling, etc., and achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

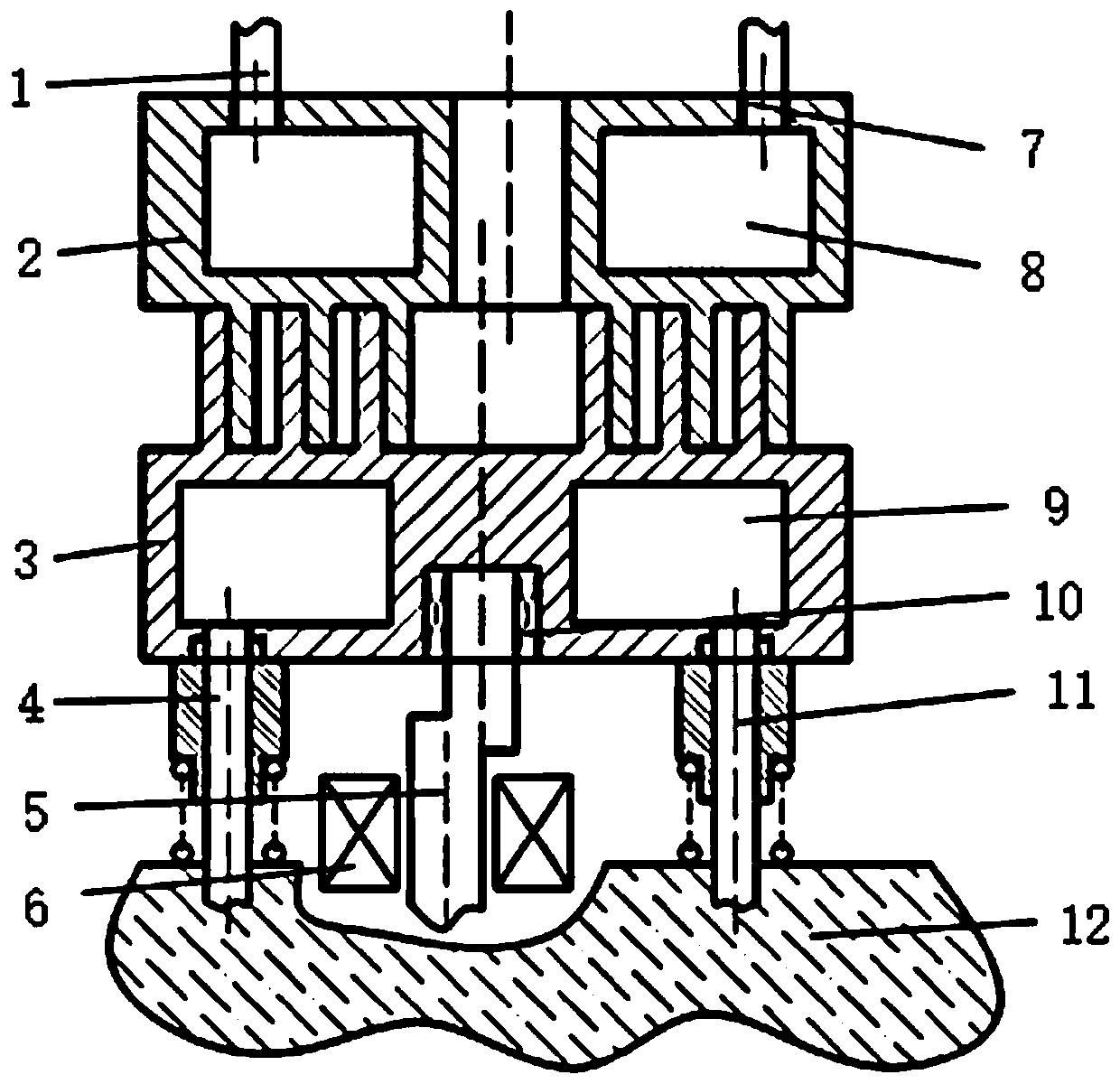

[0020] The main components of the water-cooled oil-free scroll compressor of the present invention include a fixed scroll 2 and a movable scroll 3. When the compressor is working, the motor 6 drives the main shaft 5 to drive the movable scroll 3 to compress, and the main shaft 5 is installed on the main shaft bearing 10 superior. The cooling system works at the same time, and the cooling water circulates to cool the fixed scroll 2 and the movable scroll 3 . Cooling water enters the static scroll cooling channel 8 on the back side from the static scroll inlet pipe 1, and flows out of the static scroll 2 through the static scroll outlet pipe 7 after the cooling water exchanges heat with the static scroll 2. Another stream of cooling water flows from the dynamic and static joint 4 of the scroll at the water inlet end into the movable scroll cooling channel 9 on the back, and the cooling water exchanges heat with the movable scroll 3 and flows out of the movable scroll 3 through t...

Embodiment 2

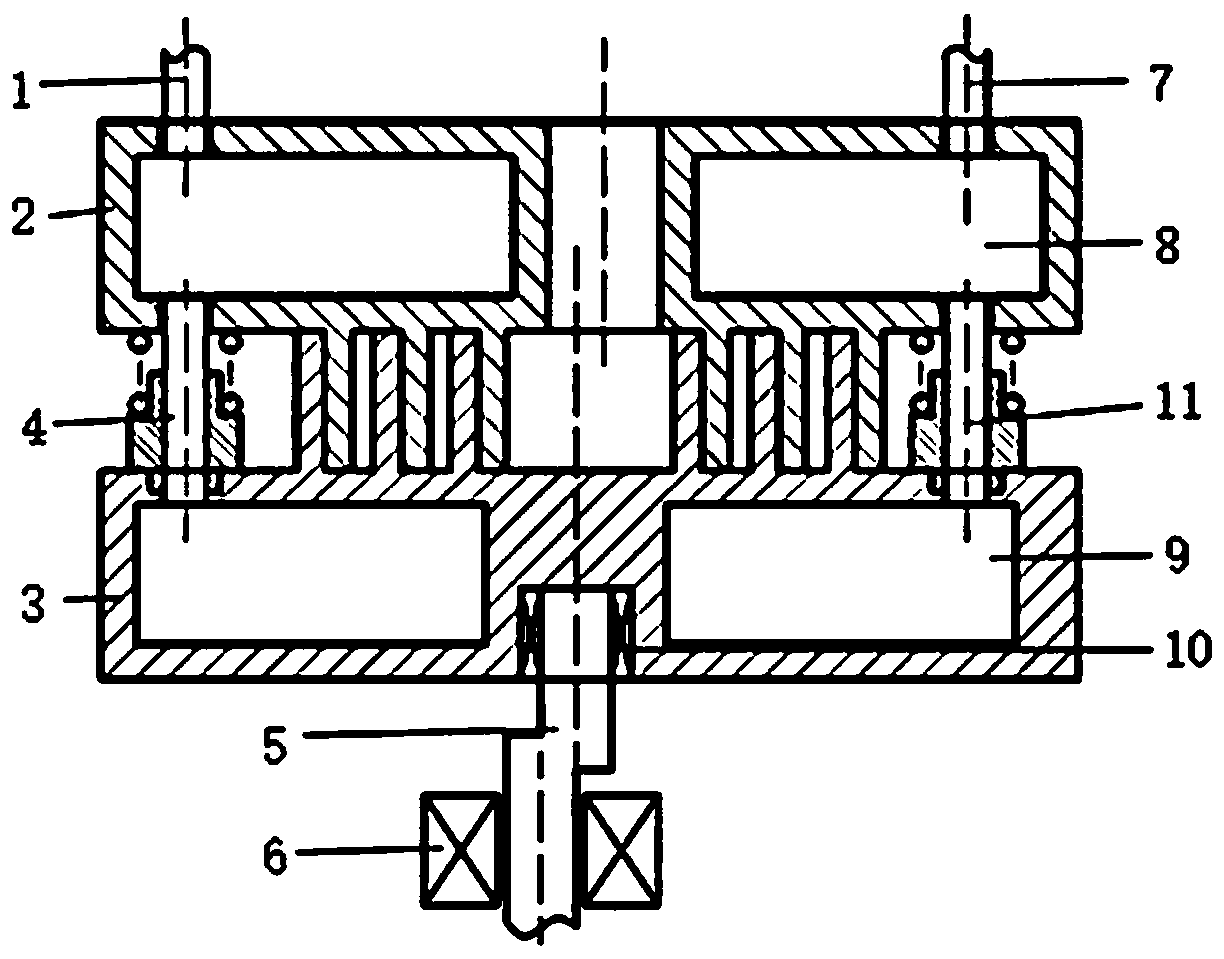

[0022] The main parts of the water-cooled oil-free scroll compressor of the present invention include a fixed scroll 2 and a moving scroll 3, and the fixed scroll 2 and the moving scroll 3 extend the scroll base laterally outside the scroll wall, so that the moving scroll can 3 and the static scroll 2 are provided with a scroll dynamic joint 4 at the water inlet end and a scroll dynamic joint 11 at the water outlet end. When the compressor is put into operation, the motor 6 drives the main shaft 5 to drive the movable scroll 3 to compress, and the main shaft 5 is installed on the main shaft bearing 10 . The cooling system works at the same time, and the cooling water circulates to cool the fixed scroll 2 and the movable scroll 3. The cooling water enters the water distribution port of the static scroll 2 from the static scroll inlet pipe 1, and the cooling water is divided into two streams, one along the The static scroll cooling channel 8 on the back flows, exchanging heat wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com