Dyeing low-temperature post-treatment auxiliary of pure polyester fabric and polyester-containing fabrics and post-treatment technology thereof

A polyester fabric, post-processing technology, applied in the field of dyeing and finishing, to achieve the effect of reducing chromaticity value, improving fastness, and excellent synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

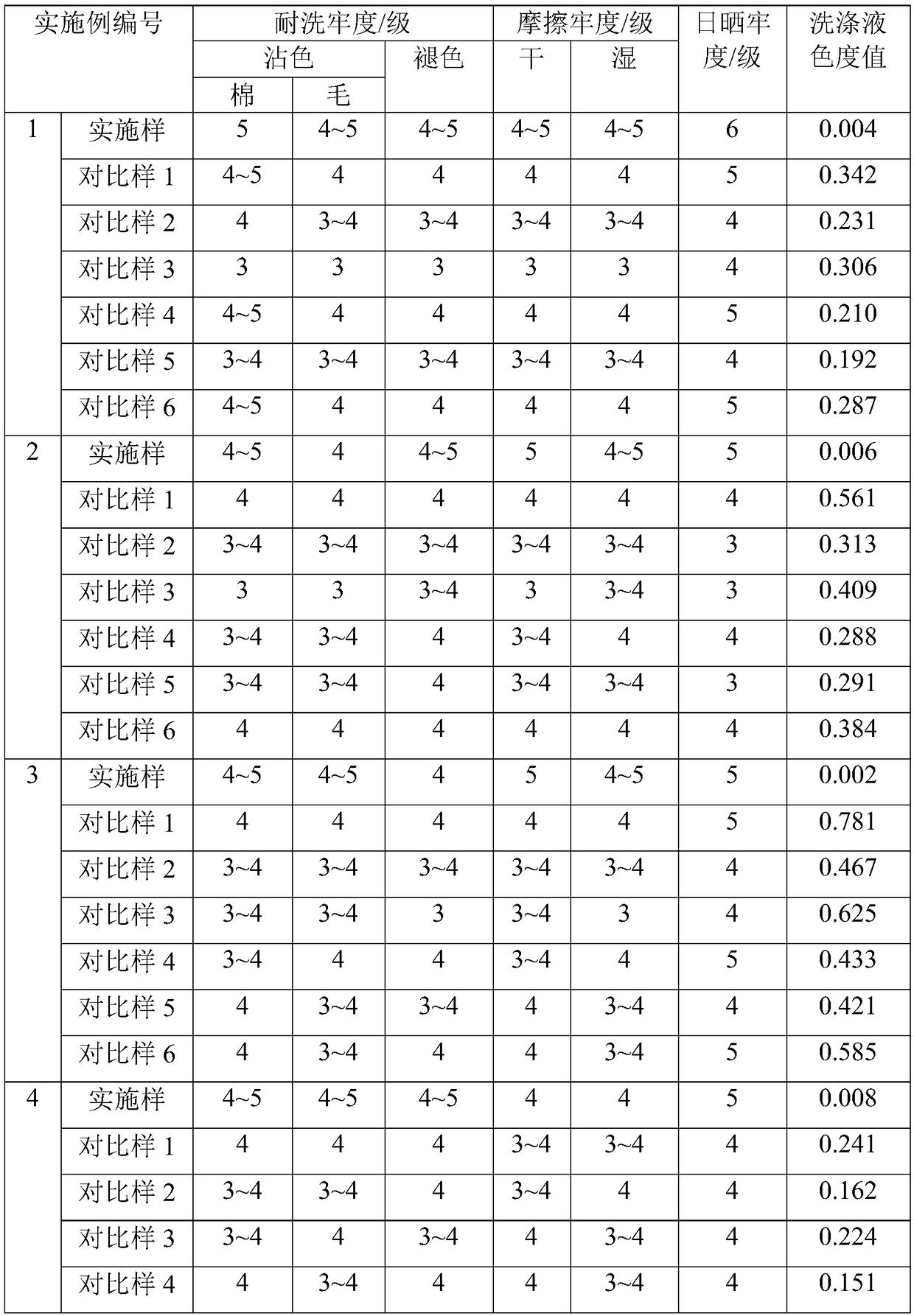

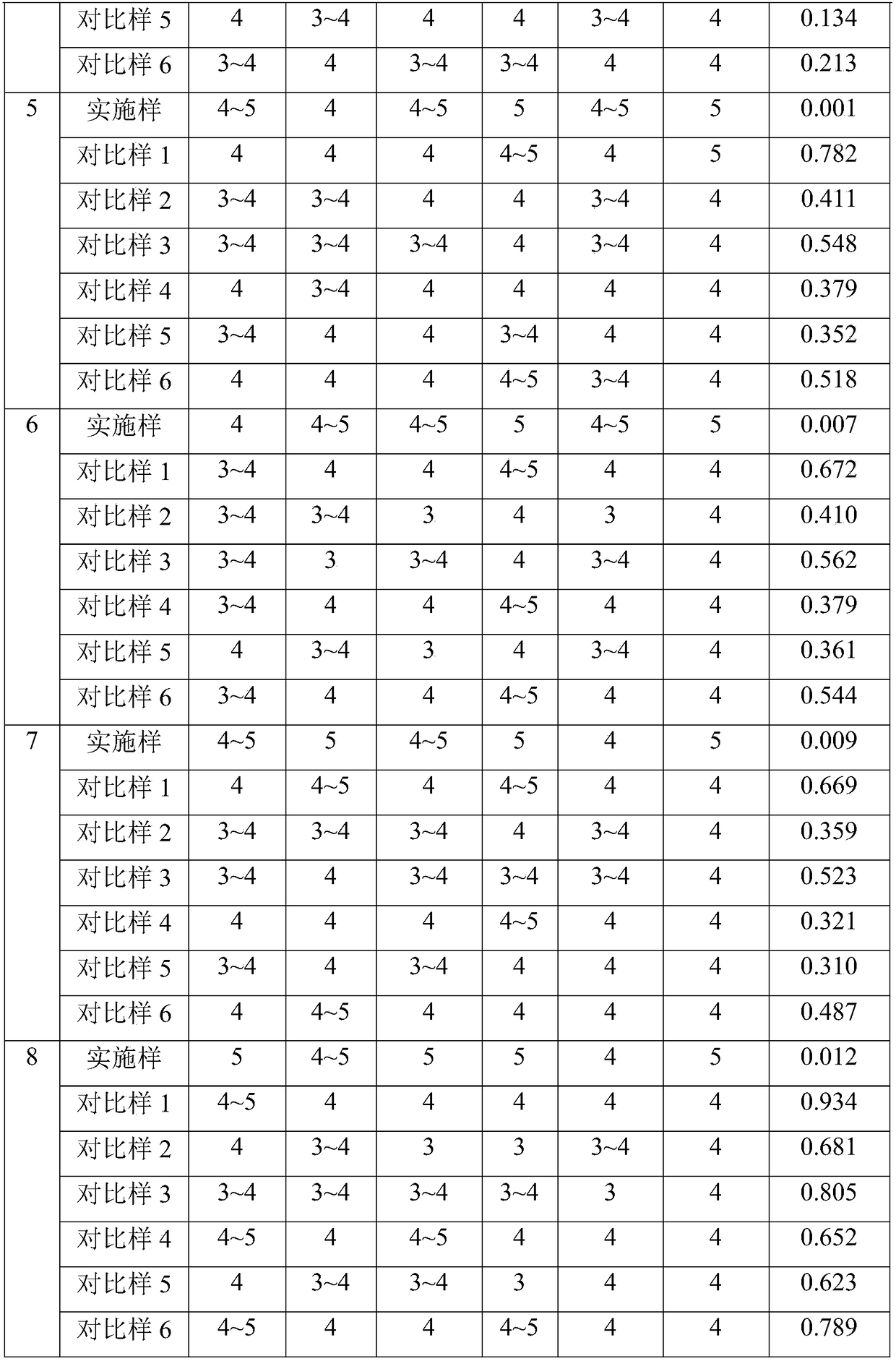

Examples

Embodiment 1

[0018] In this example, the composition of the low-temperature post-treatment auxiliary agent for pure polyester and polyester-containing fabrics after dyeing is as follows: 400g / kg diabolite powder, 200g / kg biological enzyme, and 400g / kg Gemini cationic surfactant.

[0019] The dyeing post-treatment process of pure polyester and polyester-containing fabrics in this embodiment is as follows: the dyed polyester or polyester-containing fabrics are put into the above-mentioned compounded post-treatment auxiliary solution, the post-treatment auxiliary is 5g / L, and the liquor ratio is 1:10,30 The temperature was raised to 60 °C at a rate of 1 °C / min, and then kept at a temperature of 20 min. After the post-treatment, the fabric was taken out, washed, and dried.

Embodiment 2

[0021] In this embodiment, the composition of the low-temperature post-treatment auxiliary agent for pure polyester and polyester-containing fabrics after dyeing is as follows: 300g / kg Diabaite powder, 400g / kg biological enzyme, and 300g / kg Gemini cationic surfactant.

[0022] The post-dyeing process of pure polyester and polyester-containing fabrics in this example is as follows: the dyed polyester or polyester-containing fabrics are put into the above-mentioned compounded post-treatment auxiliary solution, the post-treatment auxiliary is 2g / L, and the liquor ratio is 1:4,30 The temperature was raised to 40°C at a rate of 0.8°C / min, and then kept at a temperature of 5 minutes. After the post-treatment, the fabric was taken out, washed, and dried.

Embodiment 3

[0024] In this example, the composition of the low-temperature post-treatment auxiliary agent for pure polyester and polyester-containing fabrics after dyeing is as follows: 600g / kg diabolite powder, 200g / kg biological enzyme, and 200g / kg Gemini cationic surfactant.

[0025] The dyeing post-treatment process of pure polyester and polyester-containing fabrics in this embodiment is as follows: the dyed polyester or polyester-containing fabrics are put into the above-mentioned compounded post-processing auxiliary solution, the post-processing auxiliary is 10g / L, and the liquor ratio is 1:30,30 The temperature was raised to 50°C at a rate of 0.4°C / min, and then kept at a temperature of 15 minutes. After the post-treatment, the fabric was taken out, fully washed, and dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com