Preparation method of a degreasing and level dyeing composite emulsifier for polyester fabrics

A composite emulsifier, polyester fabric technology, applied in the direction of dyeing, textiles and papermaking, can solve the problems of high consumption of water and electricity, long production process, etc., to reduce phosphorus content, strong alkali resistance, simple and controllable synthesis process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

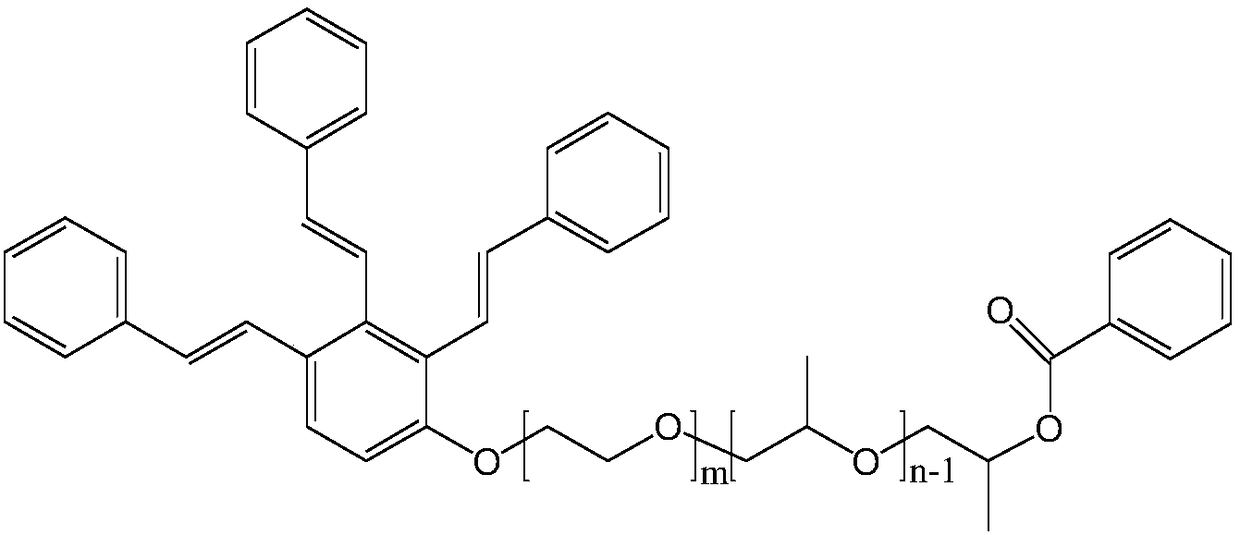

[0027] 1) Add 1200kg tristyrylphenol polyoxyethylene polyoxypropylene ether and 130kg benzoic acid into the reactor; start stirring, and raise the temperature to 80°C under the protection of nitrogen to completely dissolve the benzoic acid; then add 7kg of p-toluenesulfonic acid, heated up to 100°C, kept warm for 3 hours, and the reaction was completed to obtain tristyrylphenol polyoxyethylene polyoxypropylene ether benzoate;

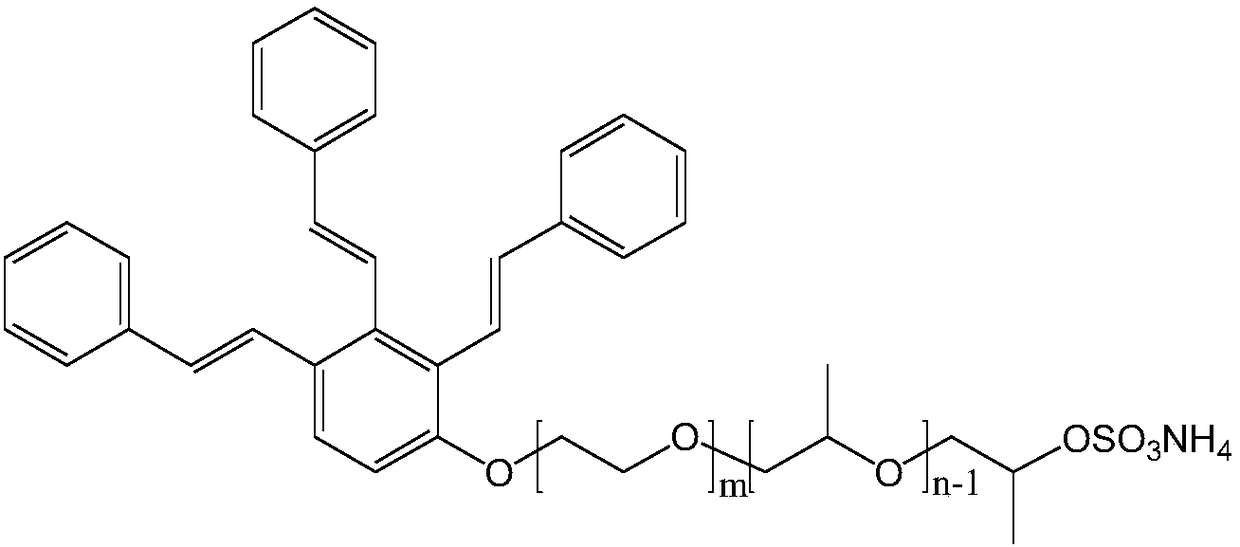

[0028] 2) Add 1200kg tristyrylphenol polyoxyethylene polyoxypropylene ether, 110kg sulfamic acid and 50kg urea into the reactor; start stirring, raise the temperature to 105°C under the protection of nitrogen, keep it warm for 3 hours, and the reaction is completed to obtain three Styrylphenol polyoxyethylene polyoxypropylene ether ammonium sulfate;

[0029] 3) Tristyrylphenol polyoxyethylene polyoxypropylene ether benzoate prepared in step 1, tristyrylphenol polyoxyethylene polyoxypropylene ether ammonium sulfate prepared in step 2, isomerized tridecyl...

Embodiment 2

[0031] 1) Add 1200kg tristyrylphenol polyoxyethylene polyoxypropylene ether and 140kg benzoic acid to the reactor; start stirring, and raise the temperature to 80°C under the protection of nitrogen to completely dissolve the benzoic acid; then add 8kg of p-toluenesulfonic acid was heated up to 110°C and kept for 3.5 hours. After the reaction was completed, tristyrylphenol polyoxyethylene polyoxypropylene ether benzoate was obtained;

[0032] 2) Add 1200kg tristyrylphenol polyoxyethylene polyoxypropylene ether, 120kg sulfamic acid and 60kg urea into the reactor; start stirring, raise the temperature to 110°C under the protection of nitrogen, keep it warm for 3.5 hours, and the reaction is completed to obtain three Styrylphenol polyoxyethylene polyoxypropylene ether ammonium sulfate;

[0033] 3) Tristyrylphenol polyoxyethylene polyoxypropylene ether benzoate prepared in step 1, tristyrylphenol polyoxyethylene polyoxypropylene ether ammonium sulfate prepared in step 2, isomerized...

Embodiment 3

[0035] 1) Add 1200kg tristyrylphenol polyoxyethylene polyoxypropylene ether and 150kg benzoic acid into the reactor; start stirring, and raise the temperature to 80°C under the protection of nitrogen to completely dissolve the benzoic acid; then add 10kg of p-toluenesulfonic acid, heated up to 115°C, kept warm for 4 hours, and the reaction was completed to obtain tristyrylphenol polyoxyethylene polyoxypropylene ether benzoate;

[0036] 2) Add 1200kg tristyrylphenol polyoxyethylene polyoxypropylene ether, 130kg sulfamic acid and 70kg urea into the reactor; start stirring, raise the temperature to 115°C under the protection of nitrogen, keep it warm for 4 hours, and the reaction is completed to obtain three Styrylphenol polyoxyethylene polyoxypropylene ether ammonium sulfate;

[0037] 3) Tristyrylphenol polyoxyethylene polyoxypropylene ether benzoate prepared in step 1, tristyrylphenol polyoxyethylene polyoxypropylene ether ammonium sulfate prepared in step 2, isomerized tridecy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com