308 alloy ingot and preparation method and application thereof

A technology for alloy ingot and aluminum alloy ingot, which is applied in the field of aluminum alloy and its preparation to achieve the effects of reducing casting speed, prolonging fatigue life, forming and good organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

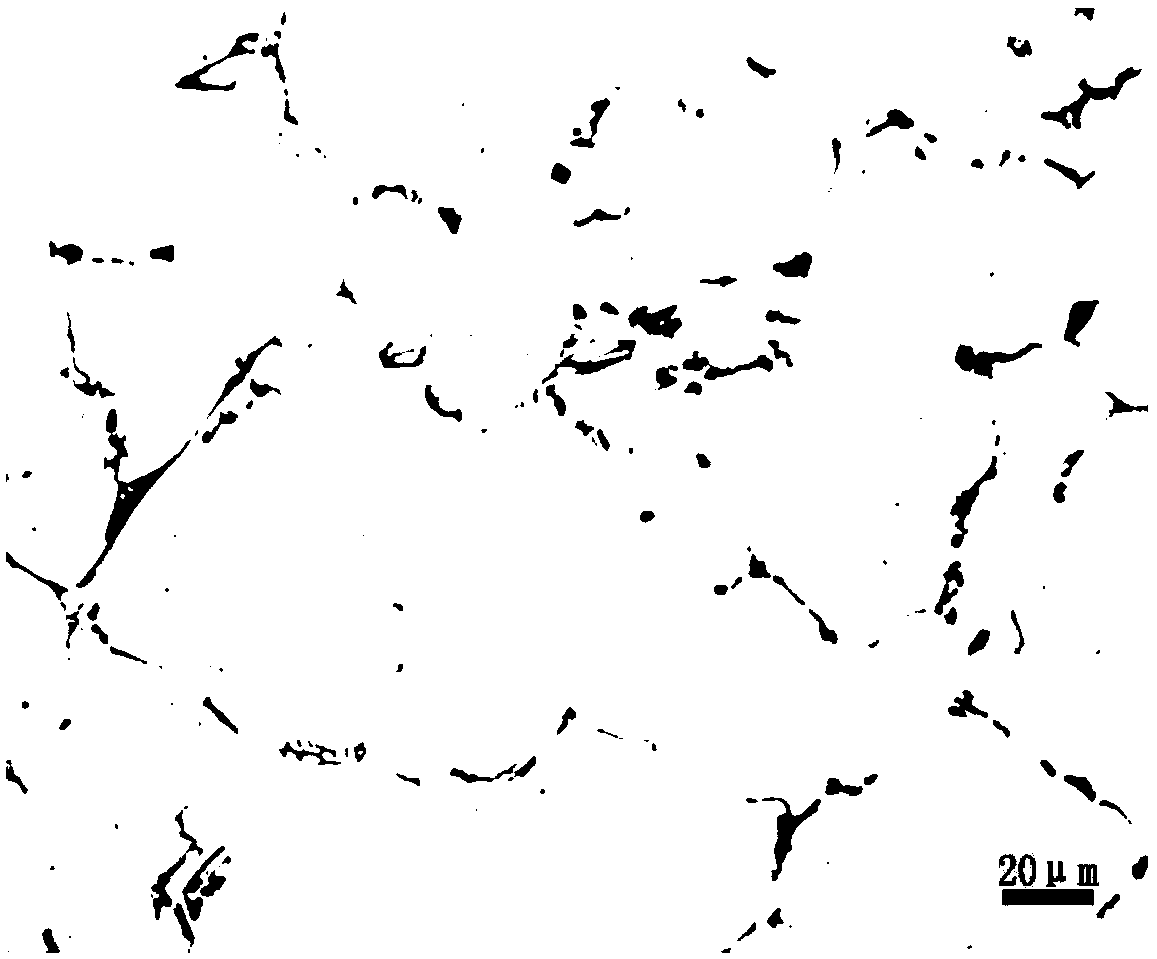

Image

Examples

specific Embodiment approach 1

[0018] Specific Embodiment 1: In this embodiment, a 308 alloy ingot, the mass percentage of each element in the 308 alloy ingot is as follows: Si: 0.2-0.6%, Fe: 0.2-0.7%, Cu: 0.3-0.8%, Mn Al production.

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass percentages of the elements in the 308 alloy ingot are as follows: Si: 0.4%, Cu: 0.6%, Mn: 1.3%, Mg: 0.6%, Zn: 0.2%, Fe: 0.4%, Ti: 0.03%, Mn+Fe≤1.8%, single impurity <0.05%, total impurity <0.15%, and the balance made of Al. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: the preparation method of a kind of 308 alloy ingot described in specific embodiment one specifically carries out according to the following steps:

[0021] 1. According to the mass percentage of each element: Si: 0.2-0.6%, Fe: 0.2-0.7%, Cu: 0.3-0.8%, Mn: 1.0-1.5%, Mg: 0.3-0.8%, Zn: 0.1-0.3%, Ti: 0.02~0.06%, Mn+Fe≤1.8%, and the balance is Al. Weigh pure aluminum ingots, pure magnesium ingots, pure zinc ingots, aluminum-silicon master alloys, aluminum-manganese master alloys, aluminum-copper master alloys, aluminum Iron master alloy and aluminum titanium boron grain refiner;

[0022] 2. Add the pure aluminum ingots, pure zinc ingots, aluminum-silicon master alloys, aluminum-manganese master alloys, aluminum-copper master alloys, and aluminum-iron master alloys weighed in step 1 into the melting furnace, and set the melting temperature to 720-760°C. After melting, stirring and slag removal, add pure magnesium ingots, and add No. 1 covering agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com