Fluid blowing roller

A fluid injection and fluid technology, applied in furnaces, heat treatment equipment, coiled strips, etc., can solve the problems of reducing the productivity of high-strength and ultra-high-strength steel plates, and achieve the effects of eliminating instability, reducing vibration, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be described in detail below with reference to the drawings. The following embodiments are only proposed to fully convey the idea of the present invention to those skilled in the art. The invention is not limited to the embodiments presented here, but may be embodied in other forms. In order to clarify the present invention, the figures that are not relevant to the description are omitted from the drawings, and the size of components may be slightly exaggerated to facilitate understanding.

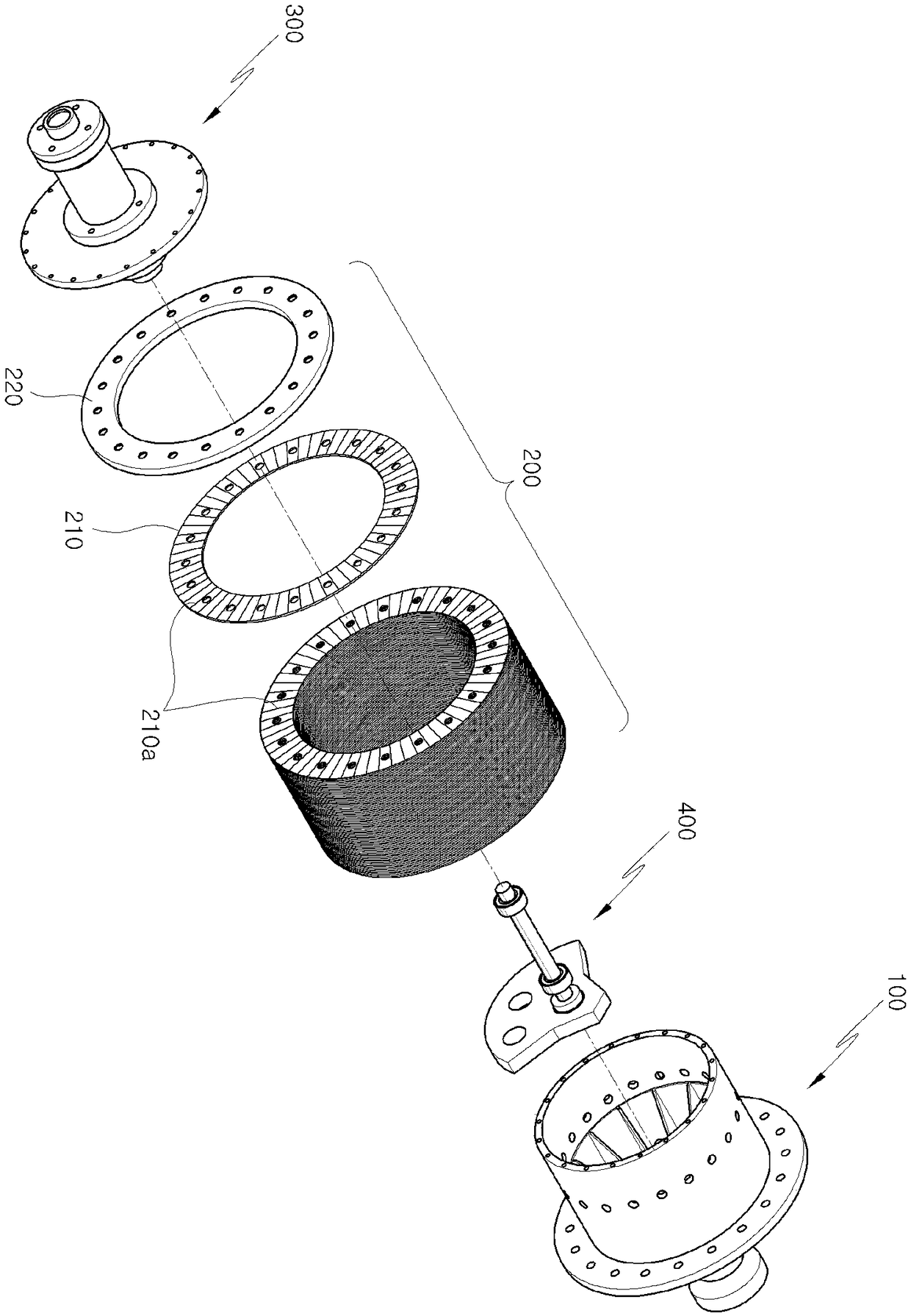

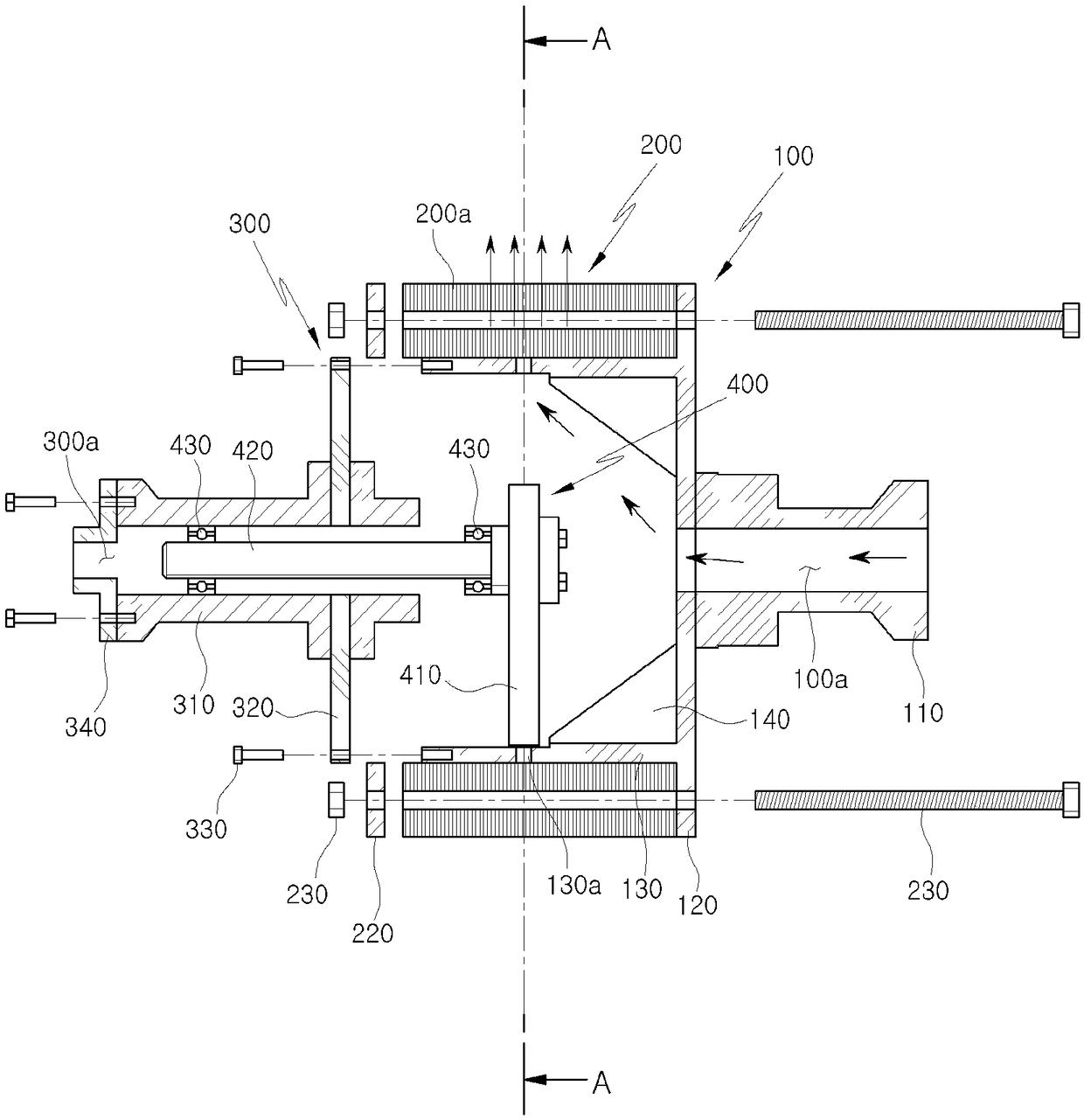

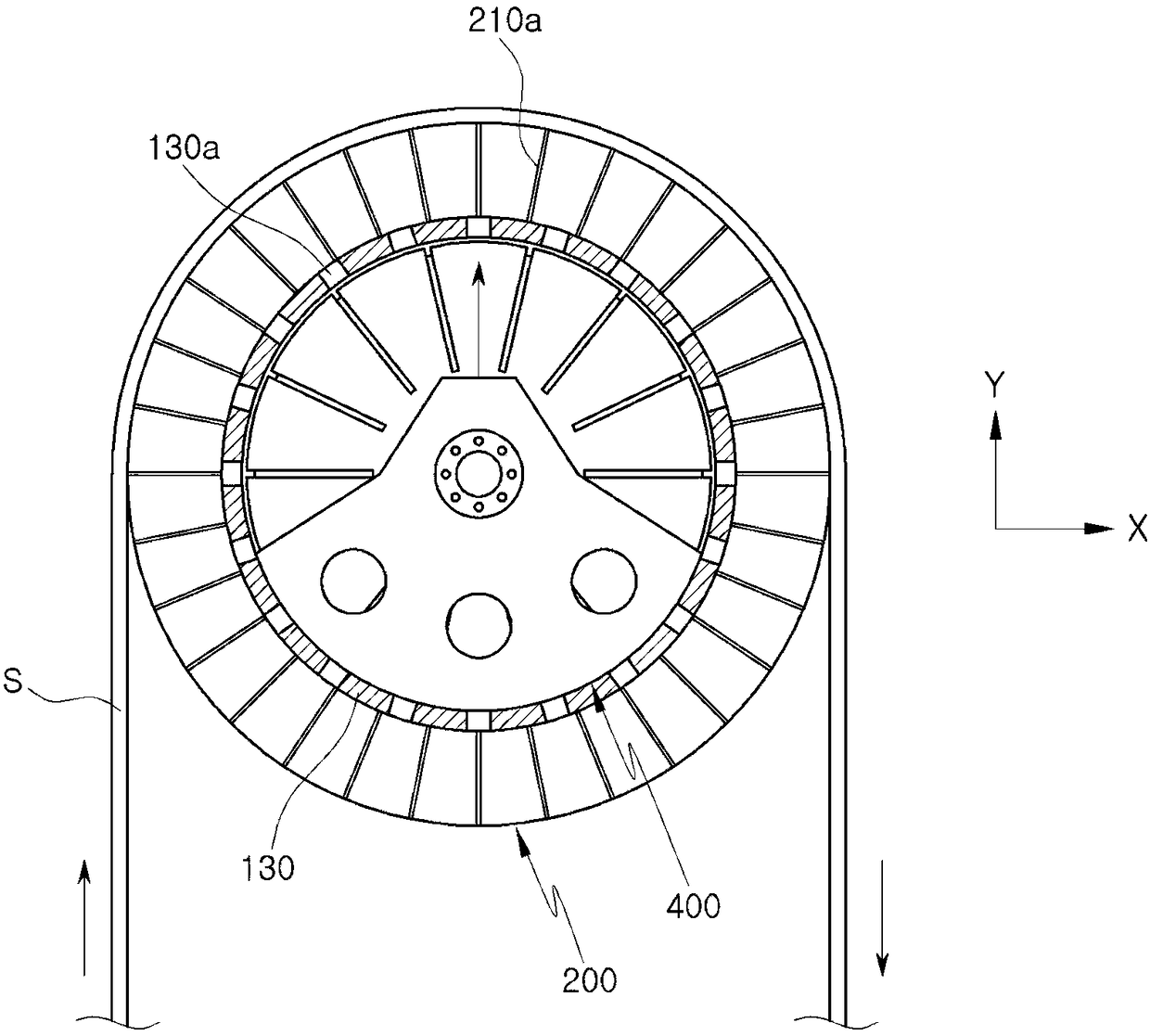

[0052] figure 1 is a structural diagram of a fluid ejection roller 10 according to an embodiment of the present invention, figure 2 is a side sectional view of a fluid ejection roller 10 according to an embodiment of the present invention, image 3 is for figure 2 A cross-sectional view of line A-A. and, Figure 4 It is a figure which shows the simulation result of the vortex which generate|occur|produces around the fluid ejection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com