Low-temperature-resistant low-density polyurethane sole product composition material and preparation method thereof

A low-density, polyurethane technology, used in the field of polyurethane elastomers, can solve the problems of poor mutual solubility of polyester and polyether, no price, decreased mechanical properties, etc., and achieve the effect of excellent low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The low-temperature-resistant low-density polyurethane sole product composite material described in this embodiment 1, the composite material is composed of A component and B component with a weight and number ratio of A:B=100:65, wherein:

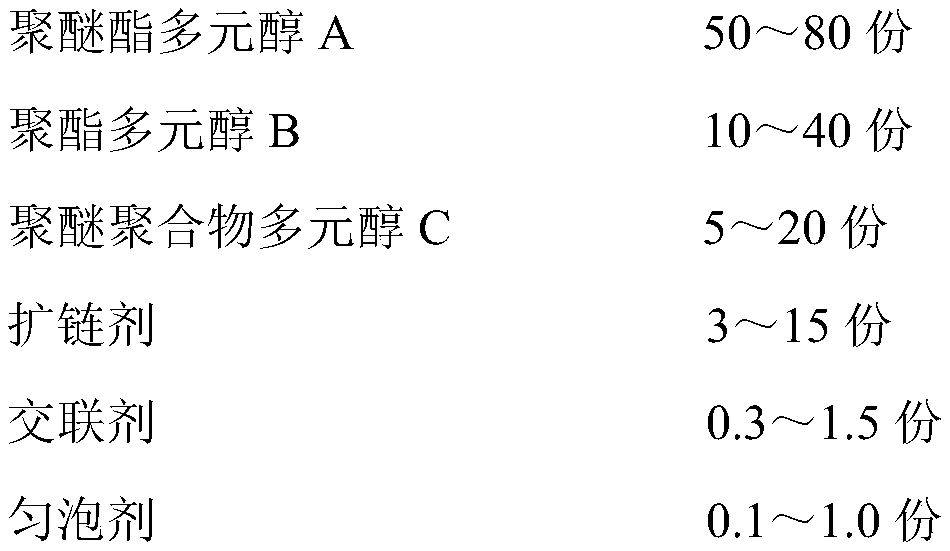

[0030] A component is measured in parts by mass, and the raw material composition is as follows:

[0031]

[0032] Component B is a polyol-modified isocyanate with an NCO content of 25%; in parts by mass, the composition of the raw materials is as follows:

[0033] Polyether ester polyol A 0 parts

[0034] Polyester polyol D 15 parts

[0035] 85 parts of isocyanate.

[0036] A component material: Polyether polyol A with a number average molecular weight of 2500 was prepared by polycondensation reaction of polyether polyol with a molecular weight of 500 and a functionality of 1.9, ethylene glycol, diethylene glycol and adipic acid; Use ethylene glycol, diethylene glycol and 1,4-butanediol to undergo polycondensation reaction wi...

Embodiment 2

[0040] The low-temperature-resistant low-density polyurethane shoe sole product composite material described in this embodiment 2, the composite material is composed of A component and B component with a weight and number ratio of A:B=100:85, wherein:

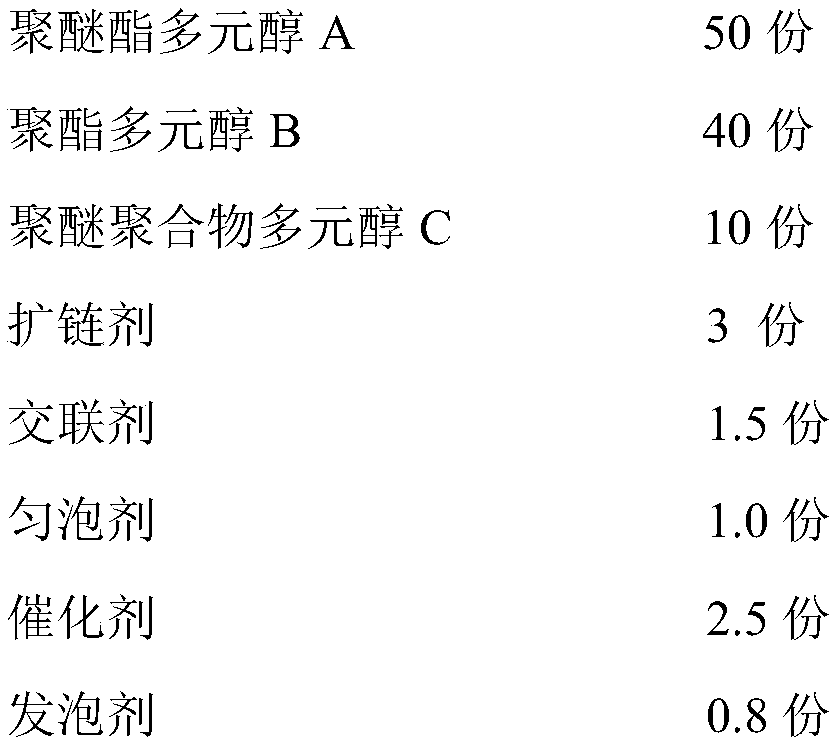

[0041] A component is measured in parts by mass, and the raw material composition is as follows:

[0042]

[0043] Component B is a polyol-modified isocyanate with an NCO content of 21%; in parts by mass, the composition of the raw materials is as follows:

[0044] Polyether ester polyol A 4 parts

[0045] Polyester polyol D 16 parts

[0046] 80 parts of isocyanate.

[0047] Component A material: Polyether polyol A with a molecular weight of 1500 and a functionality of 2.2, polyether polyol A with a number average molecular weight of 4000 was obtained through polycondensation reaction of diethylene glycol and adipic acid; , diethylene glycol and adipic acid undergo polycondensation reactions to obtain polyester polyol B w...

Embodiment 3

[0051] The low-temperature-resistant low-density polyurethane shoe sole product composite material described in this embodiment 3, the composite material is composed of A component and B component with a weight and number ratio of A:B=100:105, wherein:

[0052] A component is measured in parts by mass, and the raw material composition is as follows:

[0053]

[0054] Component B is a polyol-modified isocyanate with an NCO content of 18%; in parts by mass, the composition of the raw materials is as follows:

[0055] 10 parts of polyether ester polyol A

[0056] Polyester polyol D 15 parts

[0057] 75 parts of isocyanate.

[0058] A component material: polyether polyol with a molecular weight of 1000 and a functionality of 2.0, diethylene glycol, 1,4-butanediol and adipic acid are polycondensed to obtain a polyether ester polyol with a number average molecular weight of 2500 Alcohol A; use ethylene glycol, 1,4-butanediol and adipic acid, terephthalic acid through polyconde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com