Dechlorination method of titanium tailings and its products, slag fine powder and its application and its products

A technology for extracting titanium tailings and slag fine powder, which is applied in cement production, etc., can solve the problems of poor dechlorination effect, less heat of hydration, and high cost of concrete preparation, and achieve good hydration activity, improved dechlorination effect, and dechlorination Good effect of chlorine effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

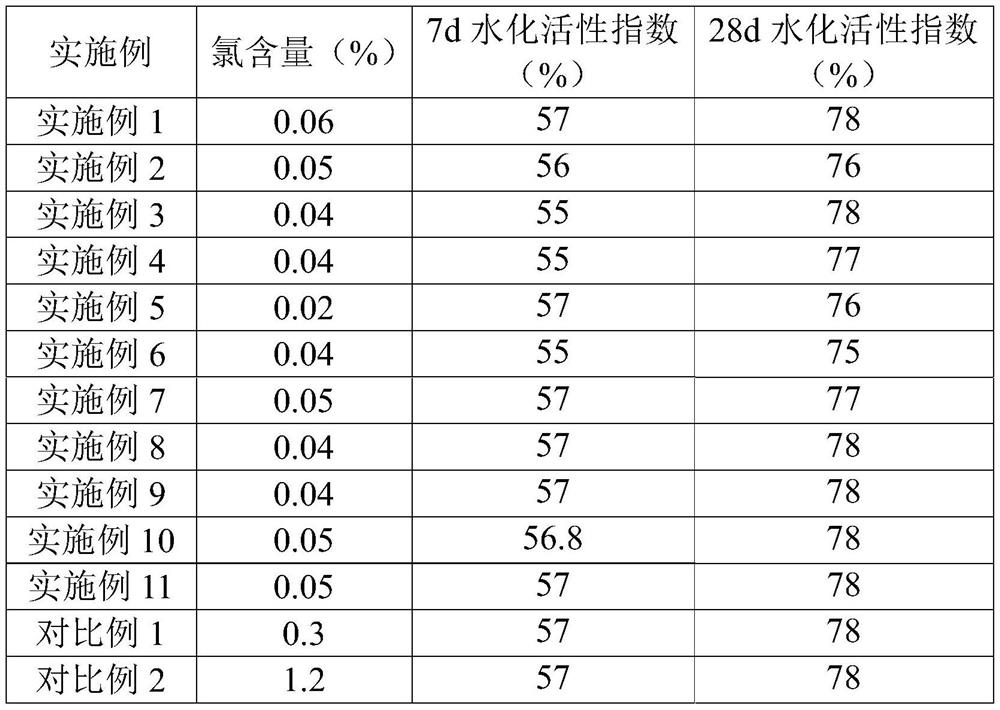

[0074] The slag micropowder can be used in the preparation of building materials, and can be used as a raw material to reduce the cost of building materials. Building materials include cement or concrete. The slag micropowder of the present invention can be used to prepare cement or concrete, thereby reducing the cost of cement and concrete.

[0075] In the fifth aspect, a construction material comprising the above-mentioned dechlorination and titanium extraction tailings or the above-mentioned slag fine powder;

[0076] The building material containing the above-mentioned dechlorination and titanium removal tailings or the above-mentioned slag fine powder also has the advantages of low cost, low chlorine content, and good hydration activity. In addition, the cost of this building material is relatively low.

[0077] Preferably, the building material comprises cement or concrete.

[0078] The cement or concrete containing the above-mentioned dechlorination and extraction of ti...

Embodiment 1

[0081] Pour the mixture of titanium extraction tailings and water with a mass ratio of 1:3 into the autoclave, the mixture of titanium extraction tailings and water accounts for 65% of the total volume of the autoclave, adjust The stirring speed is 600r / min, and the temperature is raised. After the autoclave is heated to a temperature of 100°C, the temperature is kept for 30 minutes, and then the temperature is lowered to a temperature of 25°C to obtain a turbid titanium extraction tailings liquid, and then the titanium extraction tailings turbid liquid Transfer to a plate and frame filter press for pressure filtration, and the wet dechlorination and titanium extraction tailings obtained after the pressure filtration are heated to 100°C in an oven for drying for 60 minutes to obtain the dechlorination and titanium extraction tailings.

Embodiment 2

[0083] The difference between embodiment 2 and embodiment 1 is only that, insulation 60min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com