Hyperbranched polyamide modified sodium alginate microsphere for heavy metal ion adsorption and preparation method thereof

A technology of hyperbranched polyamide and heavy metal ions, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problem of affecting the adsorption capacity of heavy metals, occupying sodium alginate, and failing to achieve adsorption. effect and other problems, to achieve the effect of low processing equipment requirements, enhanced adsorption effect, and simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

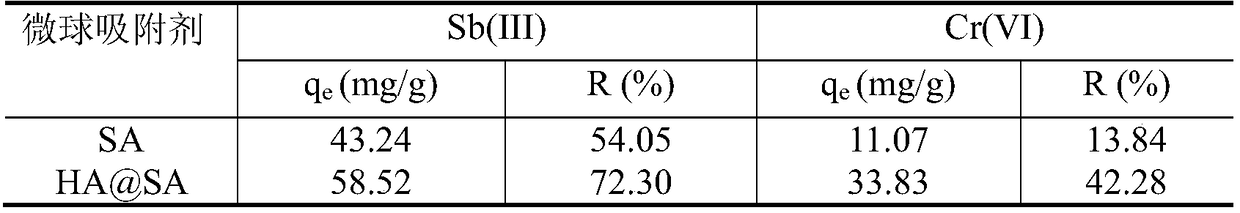

Embodiment 1

[0049] (1) 2g of sodium alginate powder was added to deionized water to prepare a 2wt% sodium alginate solution; then added dropwise to 5wt% CaCl 2 In the solution, the mass volume ratio of the two is 1:1.5, stirring while adding, the magnetic stirring speed is 800rpm, cross-linking at room temperature for 7 hours, filtering, and repeated washing with deionized water to obtain sodium alginate microspheres;

[0050] (2) Then put sodium alginate microspheres into 100mL glutaraldehyde solution with a concentration of 0.2mol / L, add 2mL hydrochloric acid with a concentration of 1mol / L, keep the temperature at 60°C, and react with magnetic stirring for 6 hours at a magnetic stirring speed of 600rpm , filter, and wash with deionized water; obtain sodium alginate microspheres containing aldehyde groups on the surface;

[0051] (3) Then put sodium alginate microspheres containing aldehyde groups on the surface into 100mL hyperbranched polyamide solution with a concentration of 2g / L, ke...

Embodiment 2

[0062] (1) Add 2g of sodium alginate powder into deionized water to prepare a 2wt% sodium alginate solution. Then add 1wt% CaCl dropwise 2 In the solution, the mass volume ratio of the two is 1:1, stirring while adding, the magnetic stirring speed is 800rpm, cross-linking at room temperature for 6 hours, filtering, and repeated washing with deionized water to obtain sodium alginate microspheres;

[0063] (2) Then put sodium alginate microspheres into 100mL glutaraldehyde solution with a concentration of 0.19mol / L, add 2mL hydrochloric acid with a concentration of 1mol / L, keep the temperature at 60°C, and react with magnetic stirring for 6 hours at a magnetic stirring speed of 600rpm , filtered, and repeatedly washed with deionized water to obtain sodium alginate microspheres containing aldehyde groups on the surface;

[0064] (3) Then put the sodium alginate microspheres containing aldehyde groups on the surface into 100 mL hyperbranched polyamide solution with a concentratio...

Embodiment 3

[0071] (1) Add 1 g of sodium alginate powder into deionized water to prepare a 1 wt % sodium alginate solution. Then add 5wt% CaCl dropwise 2 In the solution, the mass-to-volume ratio of the two is 1:1.2, stirring while adding, the magnetic stirring speed is 800 rpm, cross-linking at room temperature for 7 hours, filtering, and repeated washing with deionized water to obtain sodium alginate microspheres;

[0072] (2) Then put sodium alginate microspheres into 100mL glutaraldehyde solution with a concentration of 0.2mol / L, add 2mL hydrochloric acid with a concentration of 1mol / L, keep the temperature at 60°C, and react with magnetic stirring for 6 hours at a magnetic stirring speed of 600rpm , filtered, and repeatedly washed with deionized water to obtain sodium alginate microspheres containing aldehyde groups on the surface;

[0073] (3) Then put sodium alginate microspheres containing aldehyde groups on the surface into 100mL hyperbranched polyamide solution with a concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com