A design method of turbine high speed shaft

A design method and high-speed shaft technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as poor structural performance and long design cycle, achieve good structural performance, short design cycle, and reduce the number of cycles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

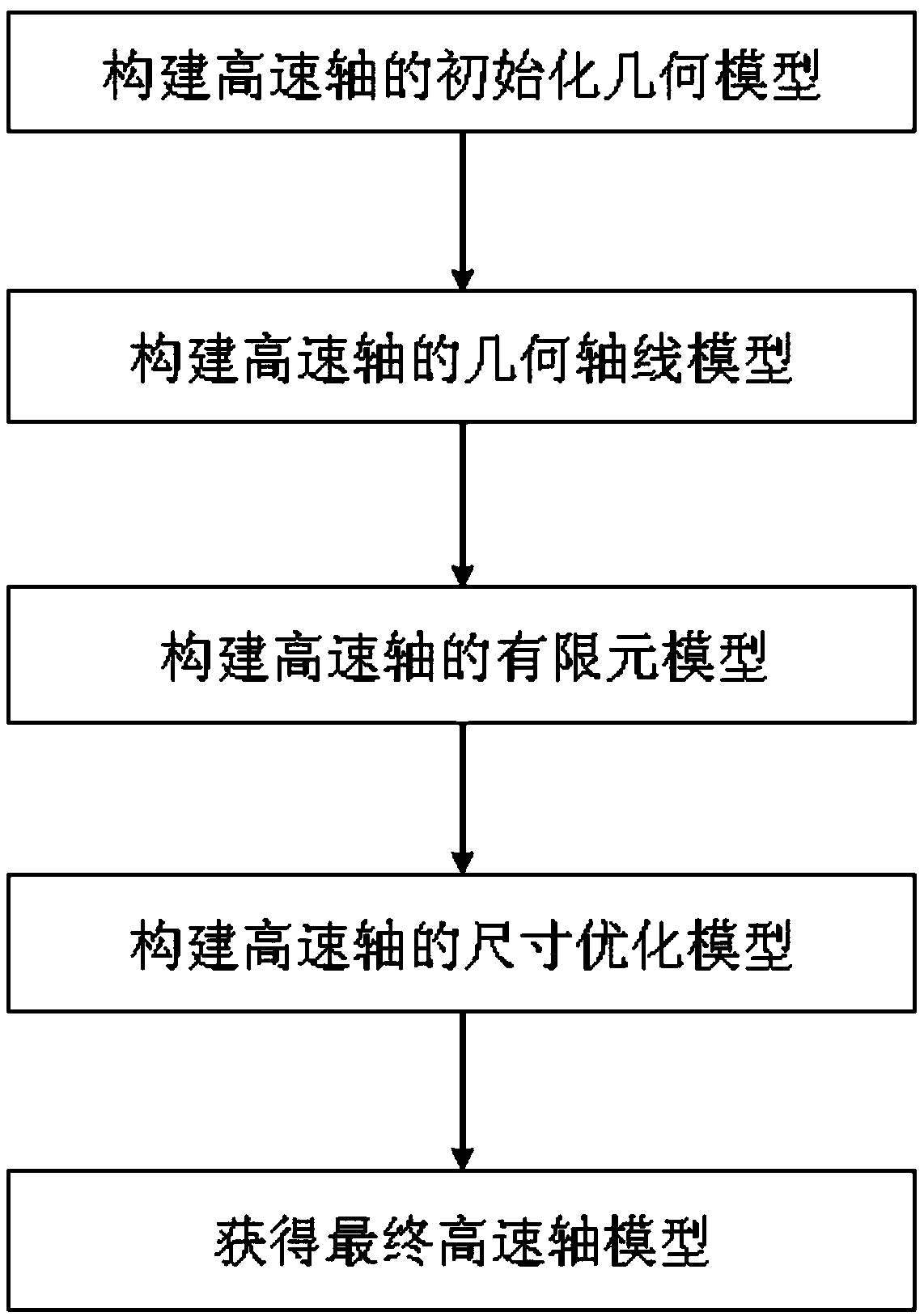

[0052] see figure 1 , a design method for a turbine high-speed shaft, the method comprising the following steps:

[0053] A. Construct the initialization geometric model of the high-speed axis

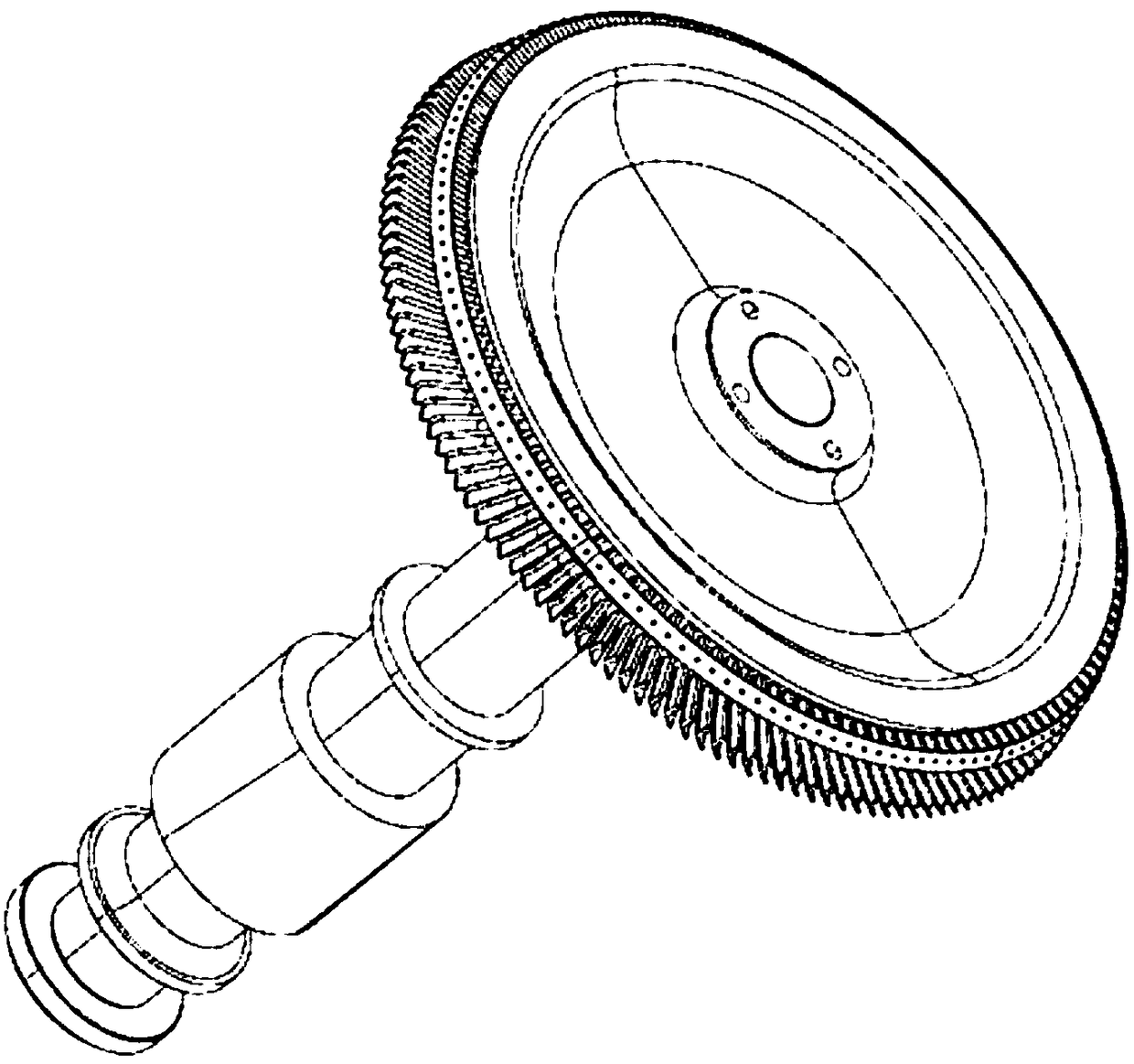

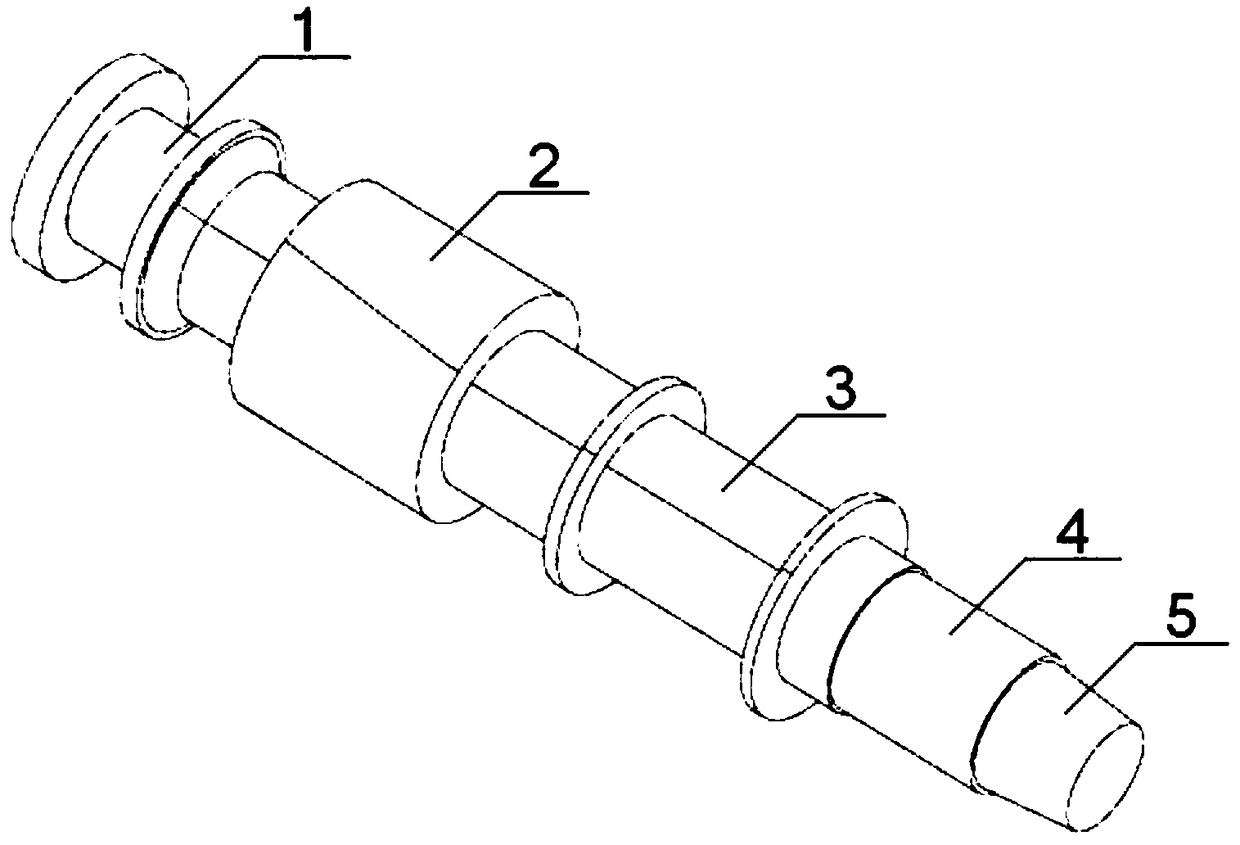

[0054] According to the design requirements and initial topology parameters, the initial geometric model of the high-speed shaft is obtained, and the initial geometric model is a three-dimensional solid model; the initial geometric model includes the No. 1 sliding bearing shaft section 1, the helical gear shaft section 2, and the No. 2 sliding bearing shaft Section 3, air seal shaft section 4, impeller assembly shaft section 5 and other intermediate transition shaft sections, such as figure 2 and image 3 shown;

[0055] B. Construct the geometric axis model of the high-speed shaft

[0056] Extract the axis of the initialization geometric model, and perform bonding processing to generate a geometric axis model of a high-speed axis composed of multiple axes, such as Figure 4 show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com