Universal wave power generation ship

A wave energy and power generation ship technology, which can be used in ocean energy power generation, engine components, special-purpose ships, etc., and can solve the problems of polluting the atmospheric environment, only working vertically, and unable to adapt to other directions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

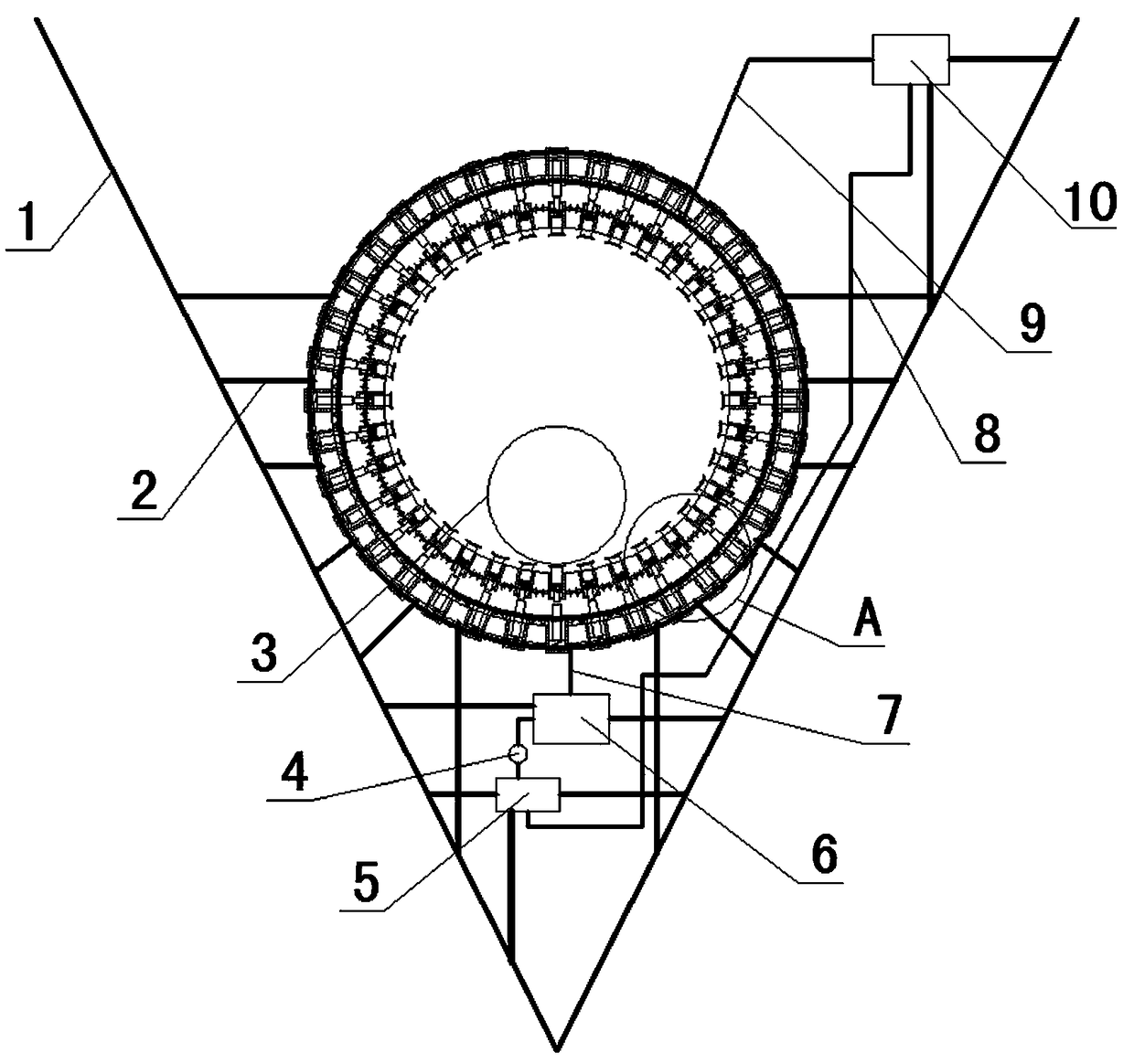

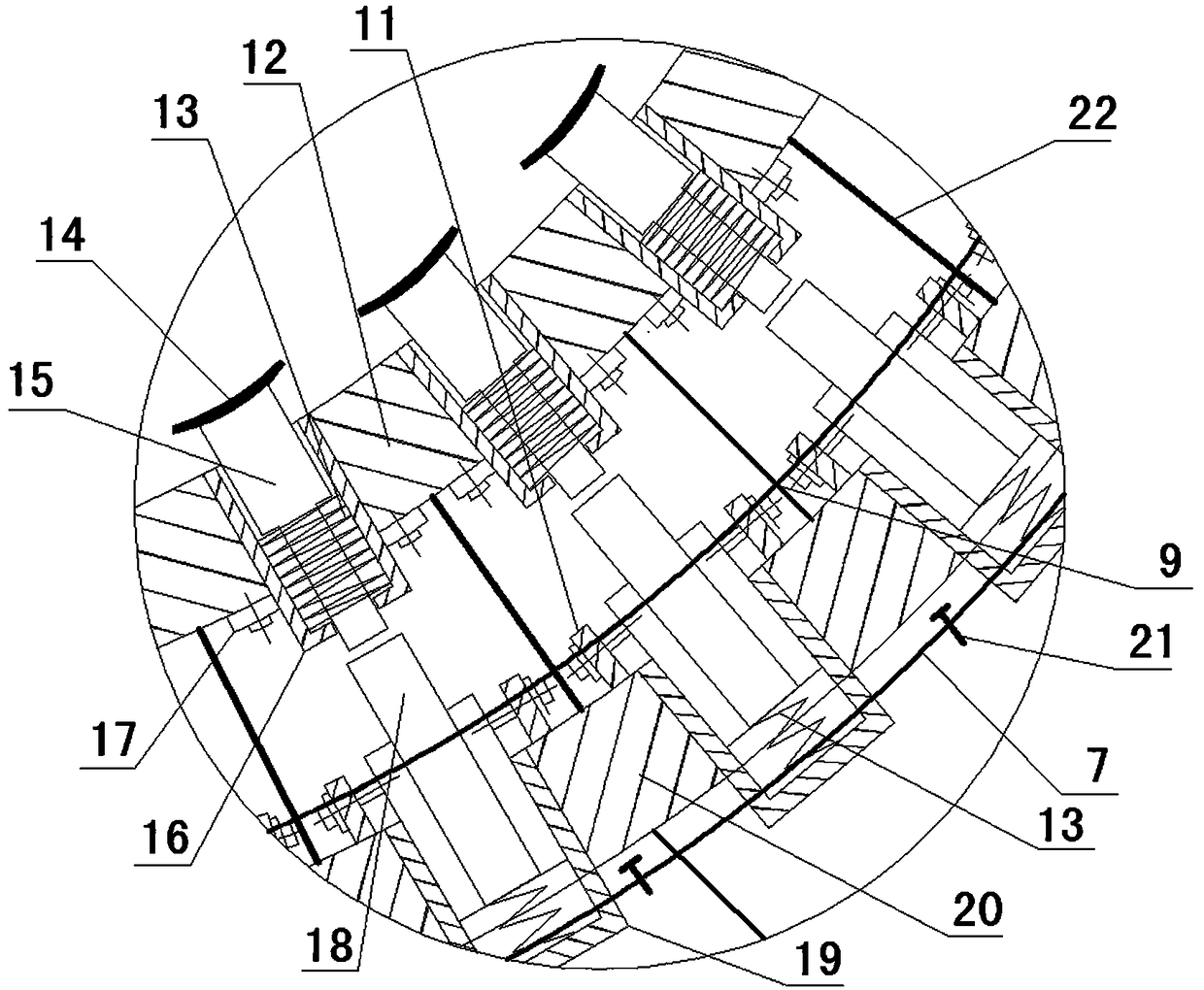

[0026] see figure 1 , figure 2 , a universal wave energy power generation ship, including a hull 1, the hull 1 has a V-shaped structure, and the hull 1 is respectively provided with a gravity fuel tank 10, an engine body 20, a high-pressure oil storage tank 6, a hydraulic motor 4, and a hydraulic generator 5, A spherical housing 12 is arranged in the engine body 20, and an engine roller 3 is arranged in the spherical housing 12. A plurality of guide sleeves 16 are evenly arranged on the spherical housing 12, and a sliding guide rod 15 is arranged in the guide sleeve 16. The return spring 13 is set on the rod 15, and the return spring 13 is used for the sliding guide rod 15 to return after being rolled by the engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com