Drum washing machine

A drum washing machine, washing machine technology, applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of inability to observe the amount of detergent in time, inconvenient use by consumers, troublesome use by consumers, etc., and achieve control of washing costs. and water cost, ensure convenience, and improve the effect of washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

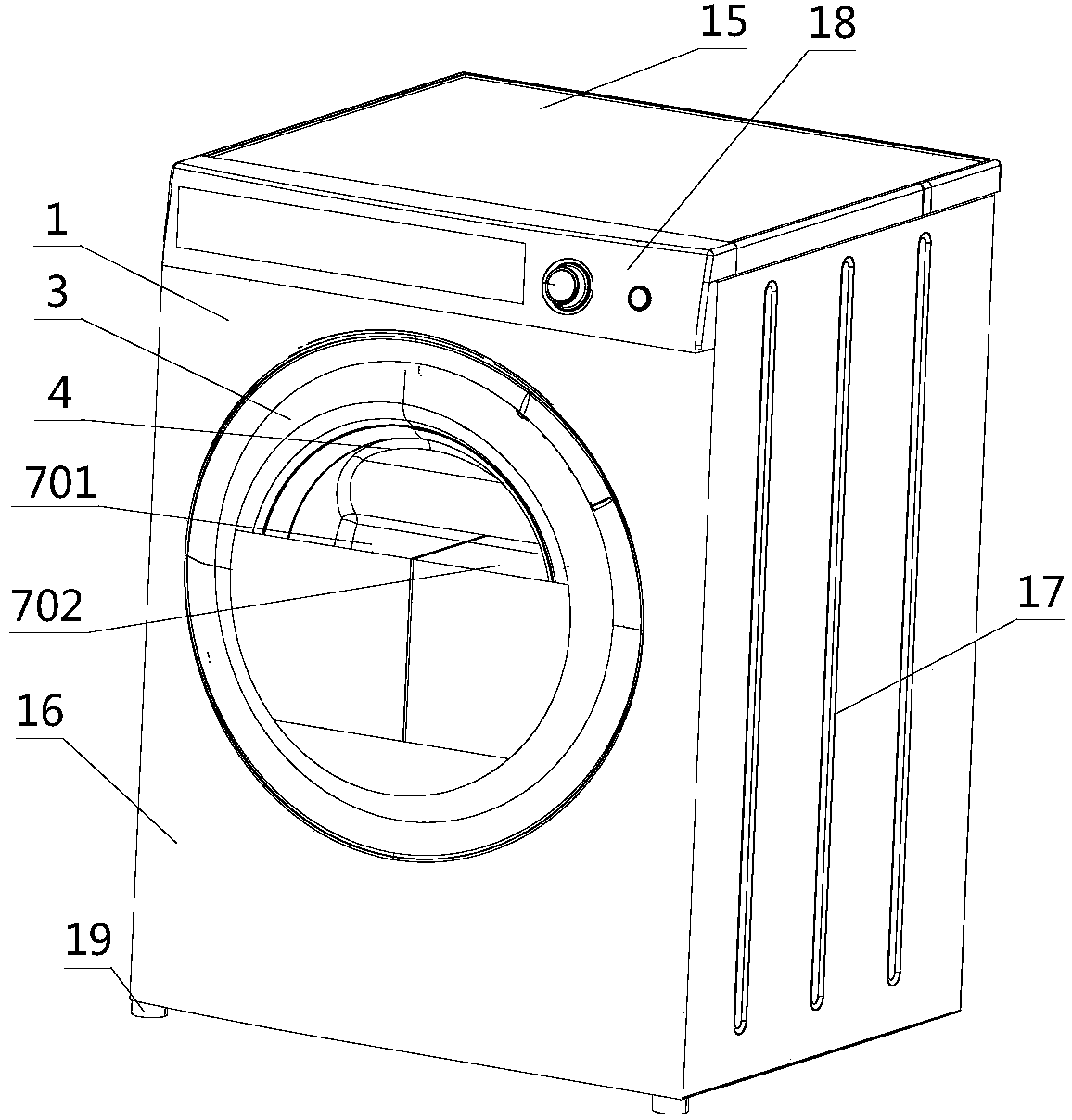

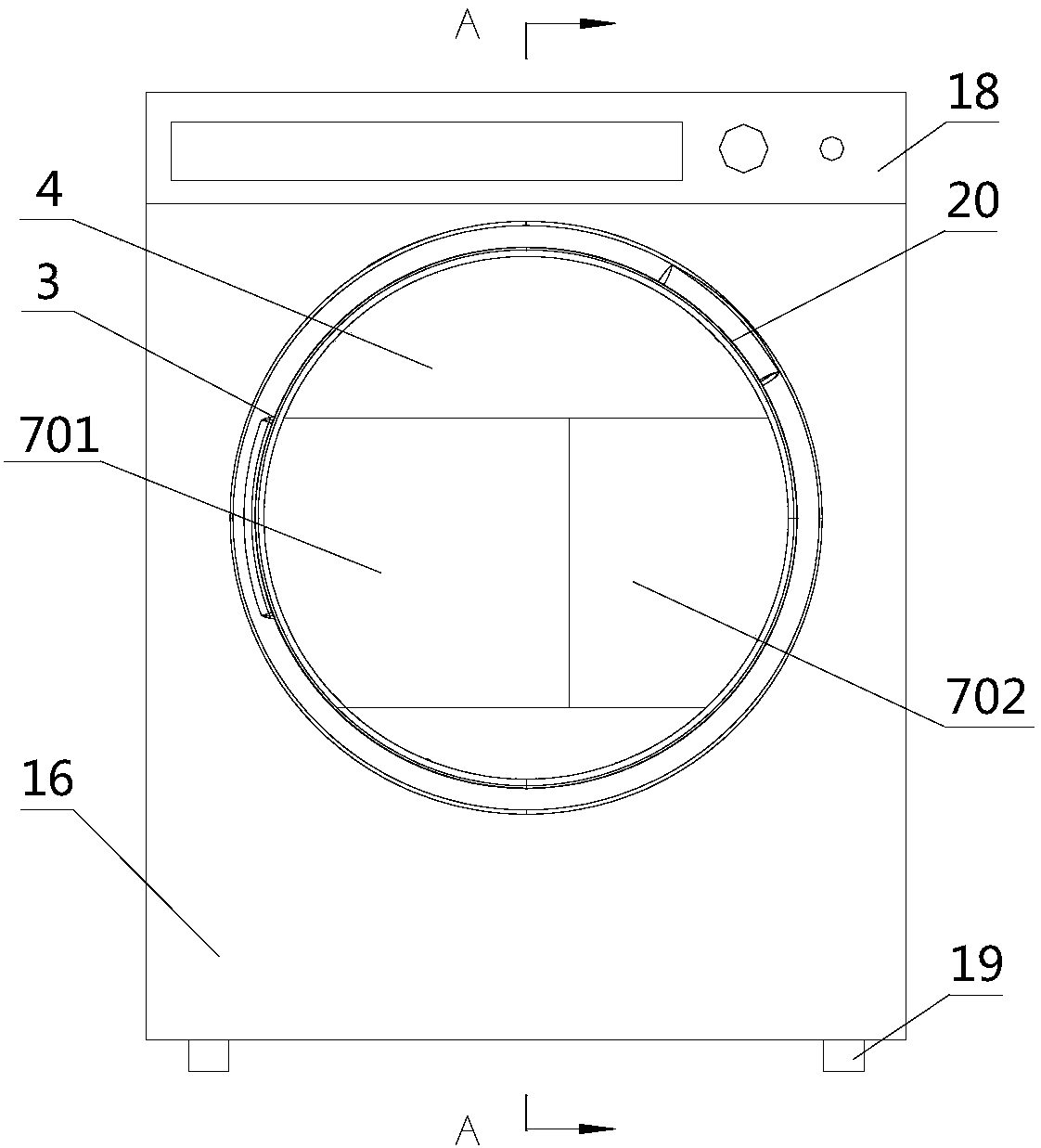

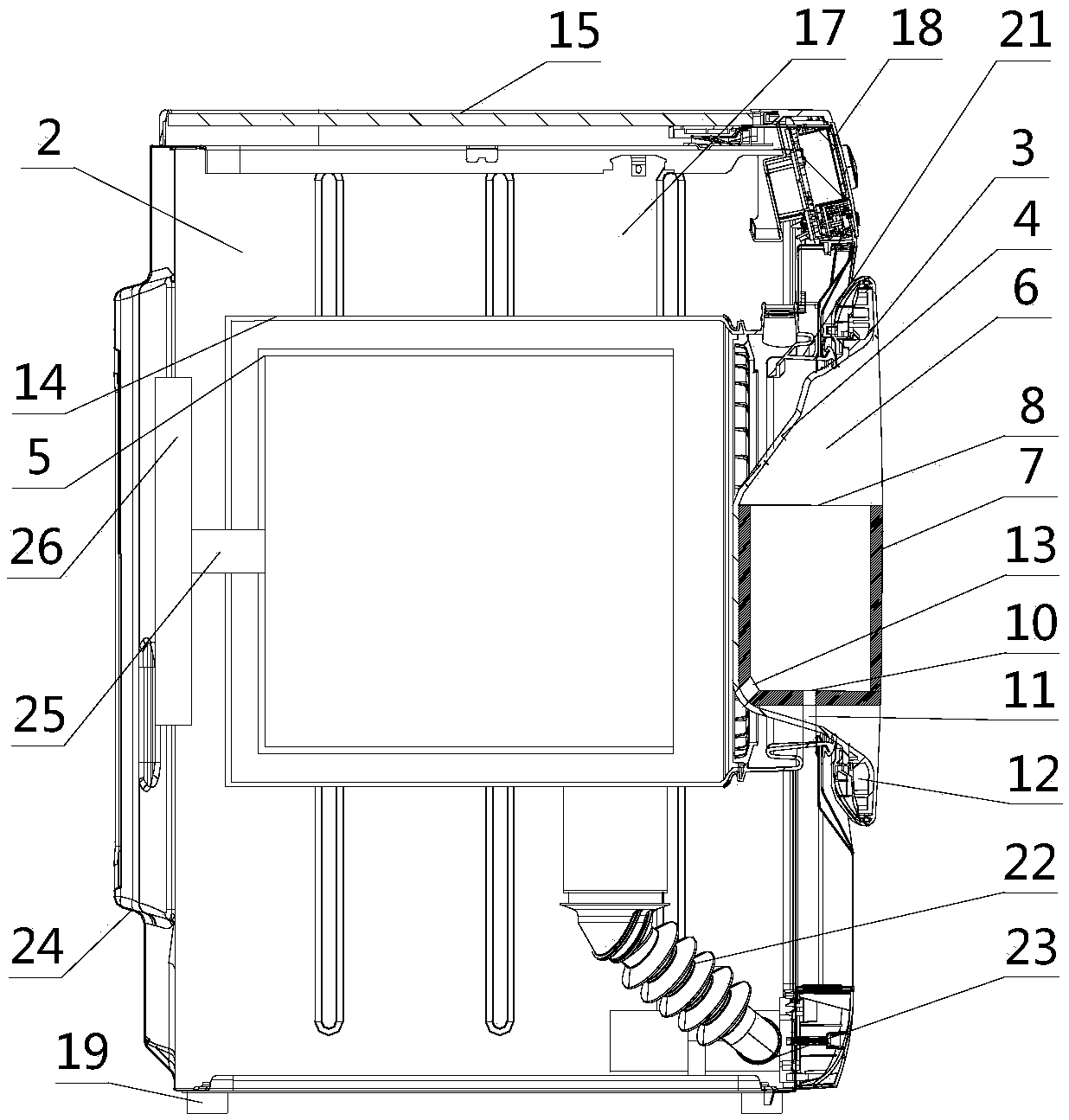

[0050] Such as Figure 1 to Figure 6 As shown, the drum washing machine described in this embodiment includes a body 1, and an accommodating chamber 2 is formed inside the body 1; a door body 3, which is movably arranged on the body 1, is used to open and close the accommodating chamber 2 Glass window 4, glass window 4 is arranged on the door body 3, in order to observe washing machine inner cylinder 5, described glass window 4 is sunken to the side of accommodating cavity 2 to form concave space 6, and described concave space 6 is outward Openings are provided for containing laundry detergent and softener, and additives are injected into the additive chamber 7 from the external opening, and at least one additive chamber 7 is arranged in the concave space 6 of the glass window 4, and the additive chamber 7 It is arranged in the concave space 6 close to the bottom side of the washing machine; the additive chamber 7 is a cavity structure with an opening at the top, and the top o...

Embodiment 2

[0057] Such as Figure 1 to Figure 6 As shown, this embodiment is a further limitation of Embodiment 1. The detergent storage box 701 and softener storage box 702 described in this embodiment are boxes of transparent materials, and consumers can observe the additive chamber 7 from the outside. According to the liquid reserves inside, it is decided before each use whether to continue to add related detergents, and detergents can also be added during use.

Embodiment 3

[0059] Such as Figure 1 to Figure 6 As shown, this embodiment is a further limitation of Embodiment 1 or Embodiment 2 above. The detergent storage box 701 and softener storage box 702 described in this embodiment are additive chambers 7 with the same size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com