A plastic deinking agent for woven bags

A technology of deinking agent and woven bag, applied in the field of plastic deinking agent for woven bags, can solve the problems of deinking of waste woven bags, low production efficiency, low profit, etc. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

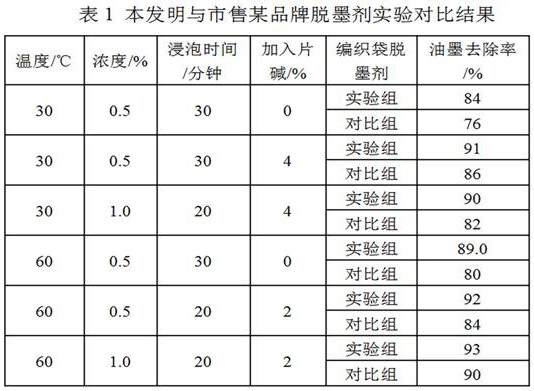

Image

Examples

Embodiment 1

[0019] A plastic deinking agent for woven bags, which is prepared from the following raw materials in parts by weight: 10-15 parts of fatty alcohol polyoxyethylene ether, 40-50 parts of fatty alcohol block polyether, 1-50 parts of polyether defoamer 3 parts, 1-2 parts of aliphatic alcohol ether, 3-5 parts of acrylic acid homopolymer, 60-70 parts of water. Wherein, the fatty alcohol polyoxyethylene ether is synthesized by fatty alcohol and 7mol or 9mol of ethylene oxide, and the carbon chain length of the fatty alcohol is C 12 -C 14, In the block of the fatty alcohol block polyether, ethylene oxide is located in the middle, and propylene oxide is located at the end. The number of ethylene oxide is 5-15, and the number of propylene oxide is 1-8. The fat The carbon chain length of the fatty alcohol of the alcohol block polyether is C 8 -C 14, The molecular weight of the acrylic acid homopolymer is 4000-5000, the solid content is 43.0-47.0%, and the pH value is 7.5-8.5.

[002...

Embodiment 2

[0023] A plastic deinking agent for woven bags, which is prepared from the following raw materials in parts by weight: 12.5 parts of fatty alcohol polyoxyethylene ether, 55 parts of fatty alcohol block polyether EH-8033, polyether defoamer DF663 2 parts, aliphatic alcohol ether JMC-50 1.5 parts, BASF polymer PA25CL 4 parts, water 65 parts. Wherein, the fatty alcohol polyoxyethylene ether is synthesized by fatty alcohol and 7mol of ethylene oxide, and the carbon chain length of the fatty alcohol is C 12 -C 14 .

[0024] The preparation method of described woven bag plastic deinking agent comprises the following steps:

[0025] Add the above weight parts of fatty alcohol polyoxyethylene ether, fatty alcohol block polyether EH-8033, fatty alcohol ether JMC-50, and BASF polymer PA25CL into the above weight parts of water, and after completely dissolving, add the above Stir the polyether defoamer DF663 in parts by weight until completely dissolved.

Embodiment 3

[0027] A plastic deinking agent for woven bags, which is prepared from the following raw materials in parts by weight: 14 parts of fatty alcohol polyoxyethylene ether, 42 parts of fatty alcohol block polyether, and 2.5 parts of polyether defoamer DF663 , 1.2 parts of aliphatic alcohol ether JMC-50, 3.3 parts of BASF polymer PA25CL, and 68 parts of water. Wherein, the fatty alcohol polyoxyethylene ether is synthesized by fatty alcohol and 9mol of ethylene oxide, and the carbon chain length of the fatty alcohol is C 12 -C 14 , in the block of the fatty alcohol block polyether, ethylene oxide is located in the middle, and propylene oxide is located at the end, the number of the ethylene oxide is 15, and the number of the propylene oxide is 8, and the fatty alcohol block The carbon chain length of the fatty alcohol of the polyether is C 8 -C 14 . Concrete preparation method is with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com