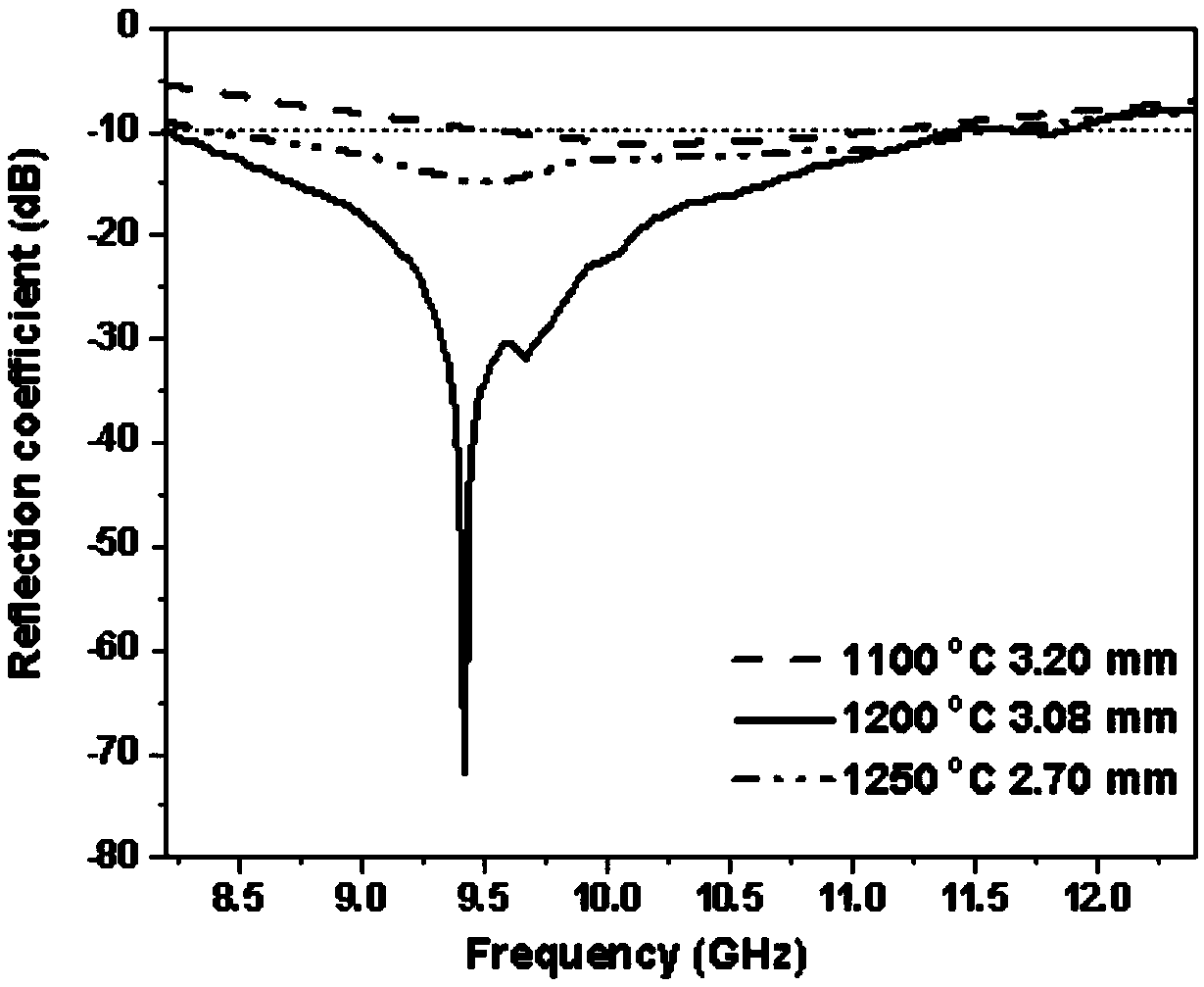

SiBCN metal-free ceramic wave-absorbing material obtained from cracking conversion of benzene ring-containing polymer and preparation method thereof

A wave-absorbing material, metal-free technology, applied in the field of wave-absorbing materials, can solve the problems of impedance matching imbalance, unfavorable material absorption performance stability, unfavorable ceramic material bearing capacity and practical application, etc., to achieve good effect of wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a benzene ring-containing polymer cracking conversion SiBCN metal-free ceramic wave-absorbing material, specifically comprising the following steps:

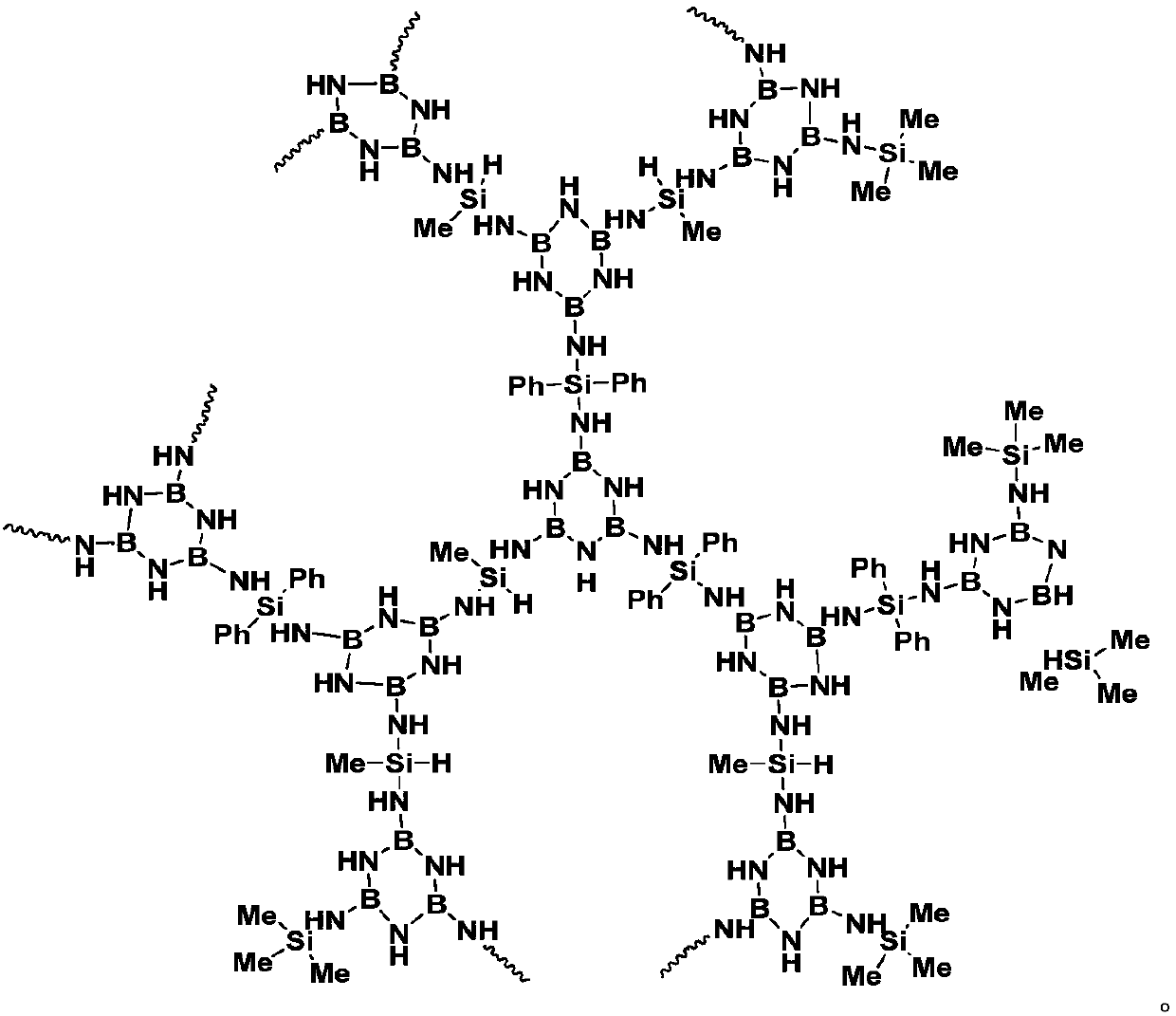

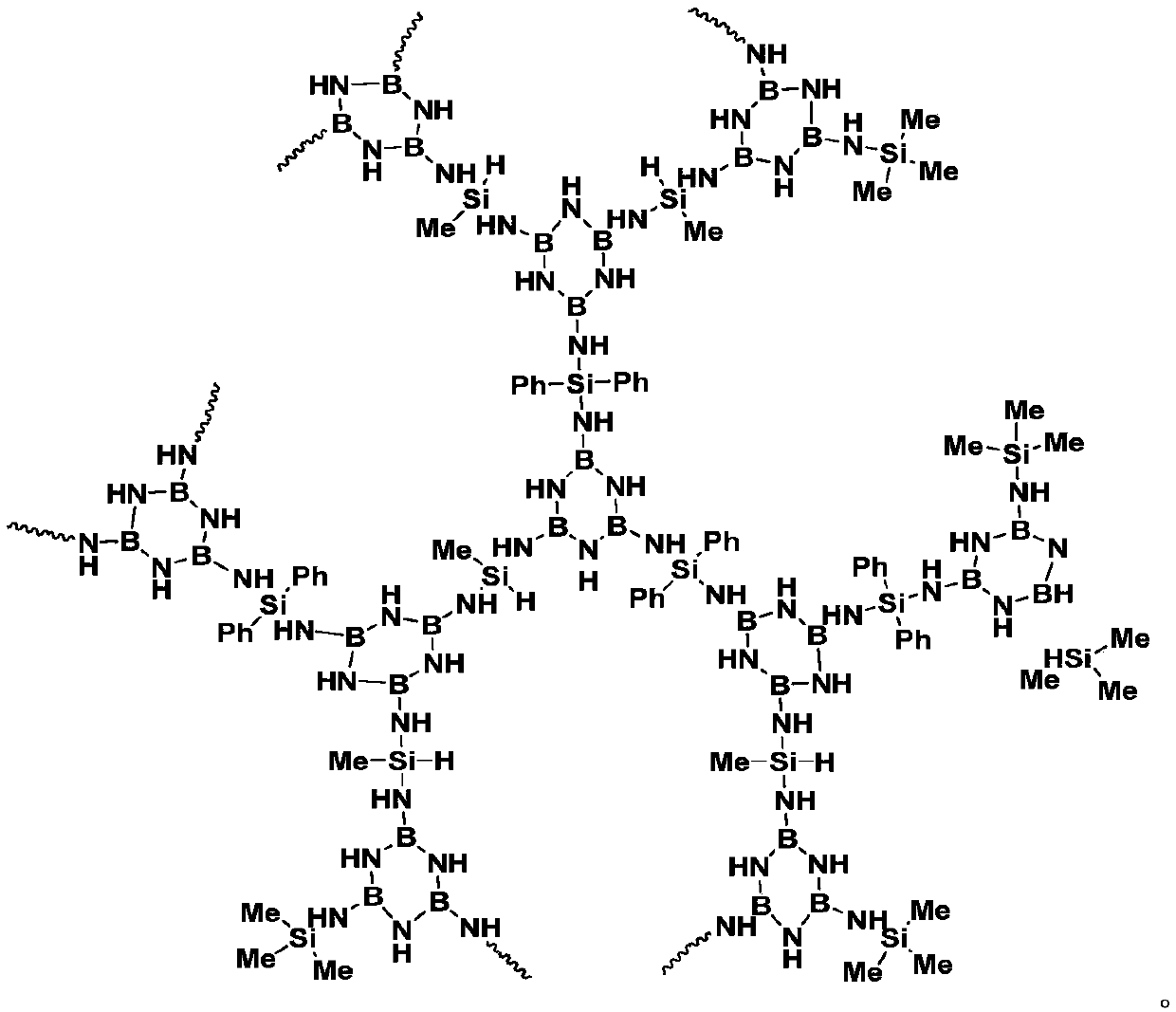

[0029] Step 1, synthesizing hyperbranched polyborosilazane containing benzene ring

[0030] 4.1g methyldichlorosilane, 9.0g dichlorodiphenylsilane and 35.5g boron trichloride are added to a dry flask of 100ml, mixed uniformly to obtain a mixed reactant; the mixed reactant is placed in an ice bath, and then At a stirring speed of 200-300r / min, dropwise add 20g of hexamethyldisilazane to the mixed reactant, react for 12h after the dropwise addition, and obtain a reaction solution 1;

[0031] Reaction solution 1 was heated to 50°C for 1 h to obtain reaction solution 2;

[0032] The temperature of the reaction solution 2 was raised to 110°C for 2 hours to obtain the reaction solution 3;

[0033] The temperature of the reaction solution 3 was raised to 250° C. for 4 hours to obtain the reaction solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reflection coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com