Processing material for chemical wastewater, preparation method and system, and control method

A chemical wastewater and preparation system technology, applied in water treatment parameter control, water/sewage treatment, natural water treatment, etc., can solve problems such as poor product quality, high pollutant content, and many biodegradable substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

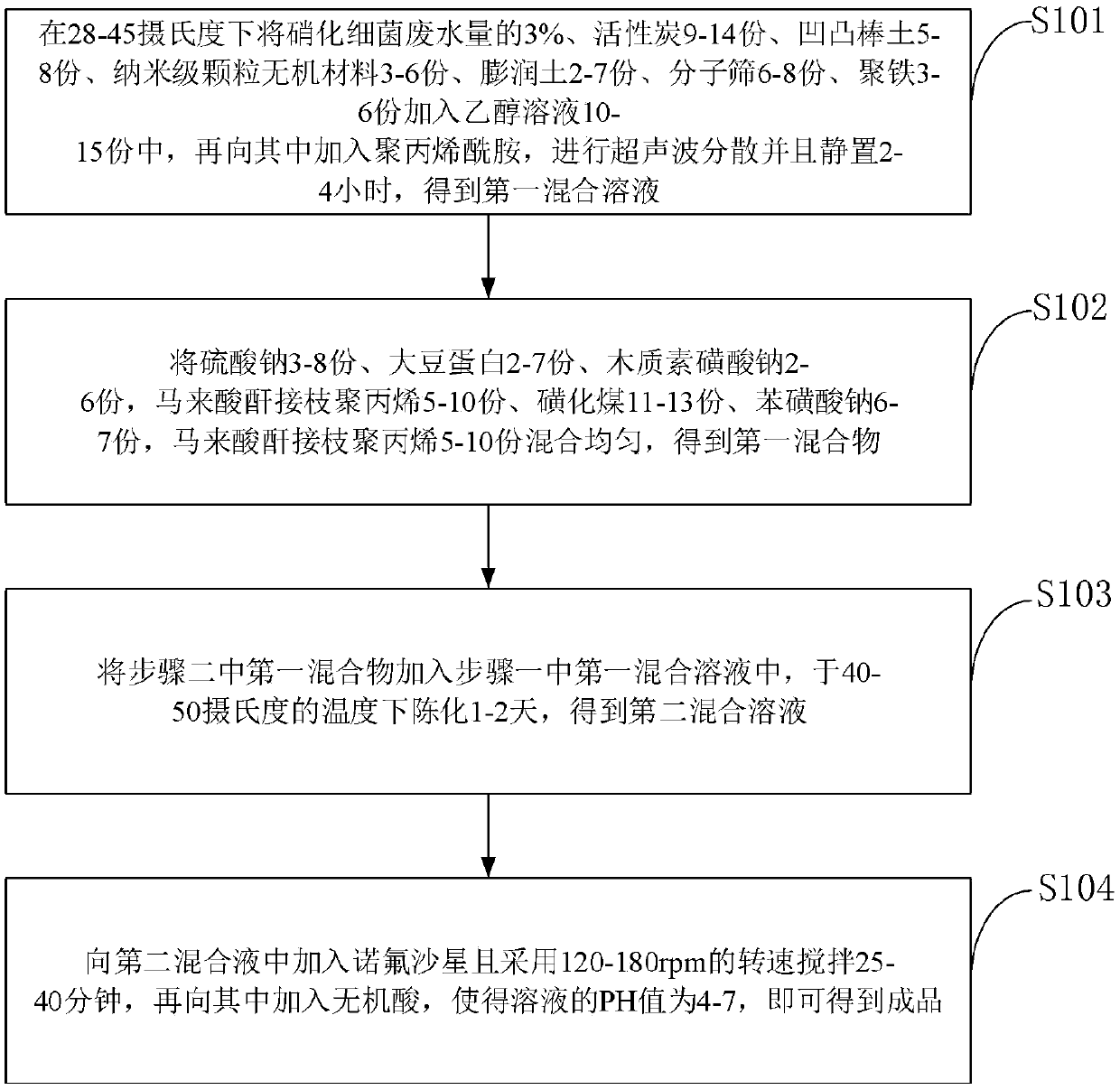

[0068] The treatment materials for chemical wastewater described in the embodiments of the present invention include: 6-8 parts of molecular sieves, 11-13 parts of sulfonated coal, 3-6 parts of polyiron, 8-11 parts of polyacrylamide, and 100% of the amount of nitrifying bacteria wastewater. 3%, 9-14 parts of activated carbon, 2-7 parts of soybean protein, 5-8 parts of attapulgite, 2-6 parts of sodium lignosulfonate, 6-7 parts of sodium benzenesulfonate, maleic anhydride grafted polypropylene 5-10 parts, 3-6 parts of nanoscale particle inorganic material, 2-7 parts of bentonite, and 3-8 parts of sodium sulfate.

[0069] The nitrifying bacteria are Cody nitrifying bacteria, which are added according to 3% of the waste water.

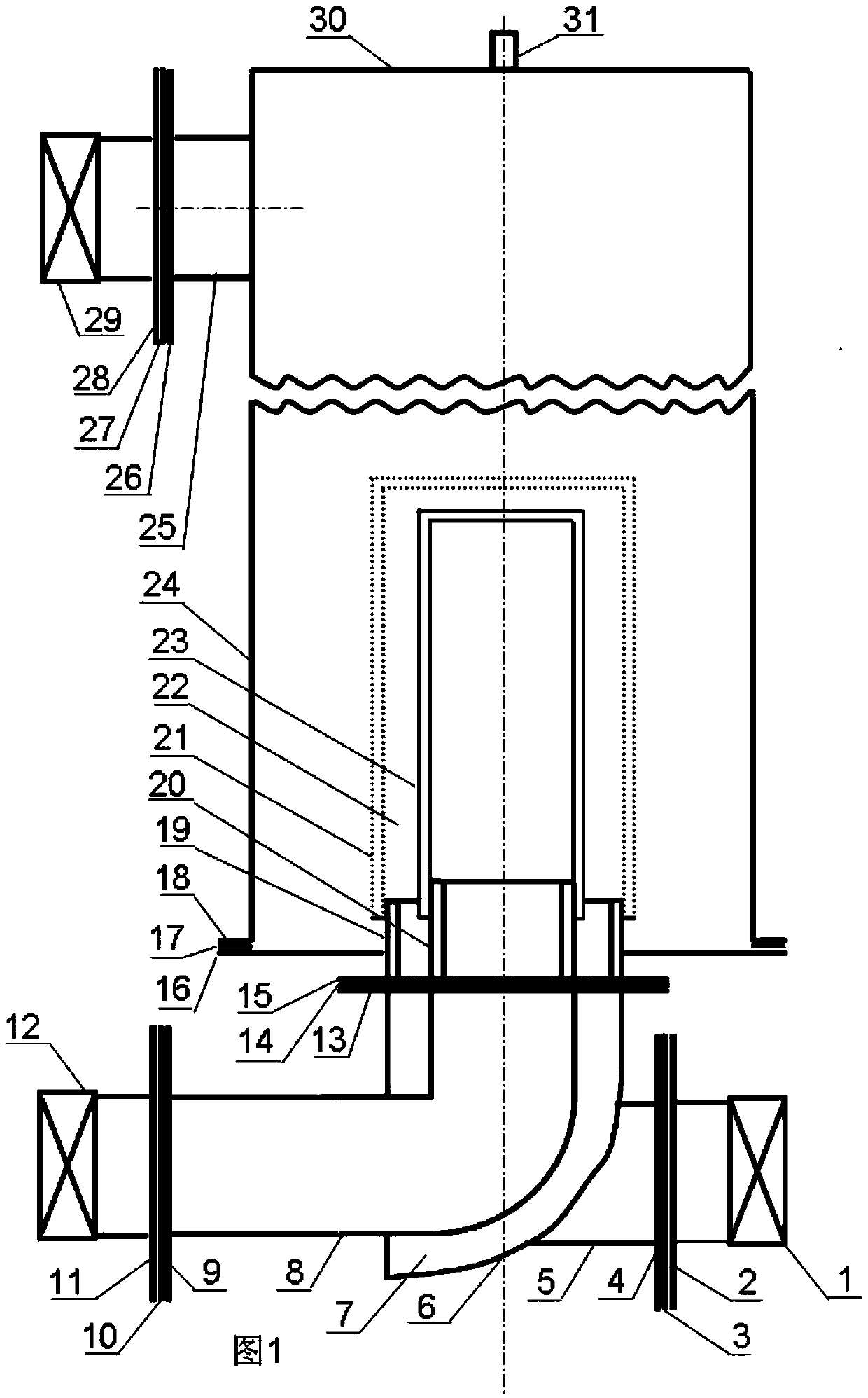

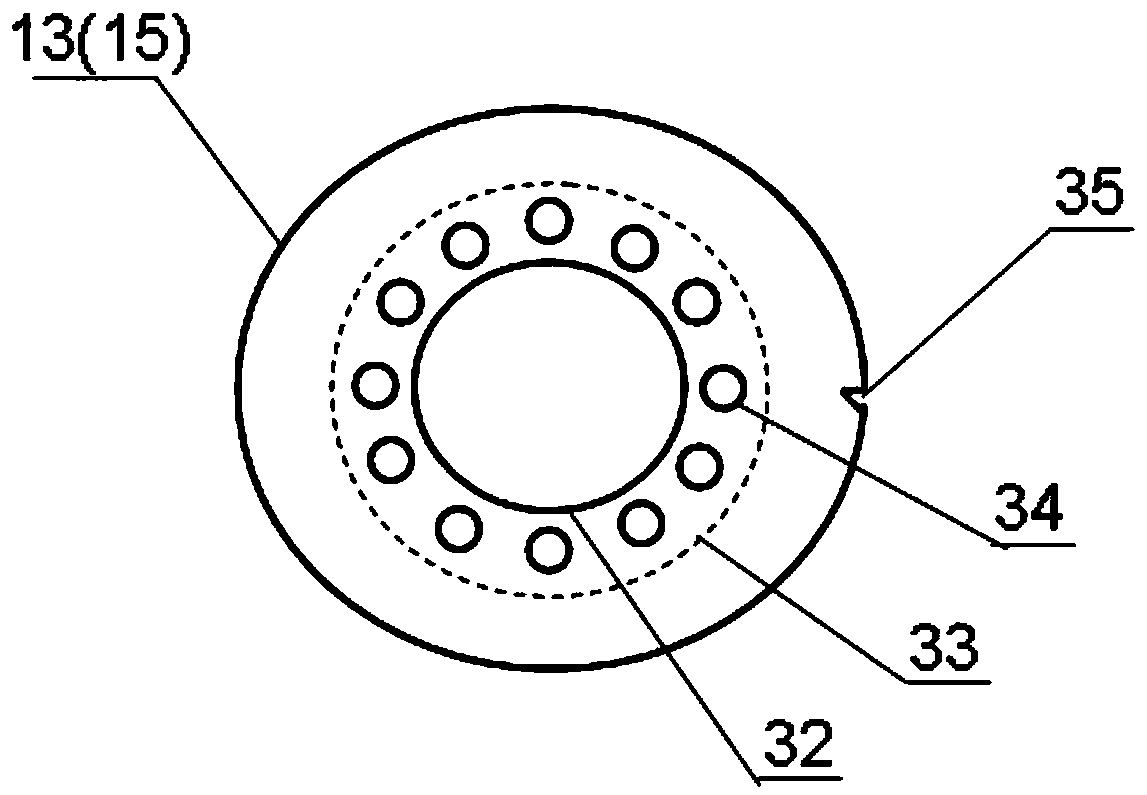

[0070] Such as figure 1 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com